Key Takeaways

- The Crisis is an Opportunity: While many see Puerto Rico’s 219% electricity cost premium as a crippling burden, savvy manufacturers are leveraging it to forge a powerful competitive advantage that insulates them from future shocks.

- A Hidden Lifeline Exists: Over $185 million in dedicated green energy funding is available to manufacturers, offering up to 50% rebates for renewable energy projects that many companies are not fully utilizing.

- Resilience Equals Revenue: By implementing independent microgrid solutions, companies like CooperVision and Eaton are not just surviving hurricane season—they are guaranteeing 100% uptime, protecting millions in revenue while competitors stand still.

- The ROI is Real and Rapid: With the right strategy, payback periods for comprehensive energy solutions are often less than 3 years, delivering sustained operational savings that drop directly to the bottom line.

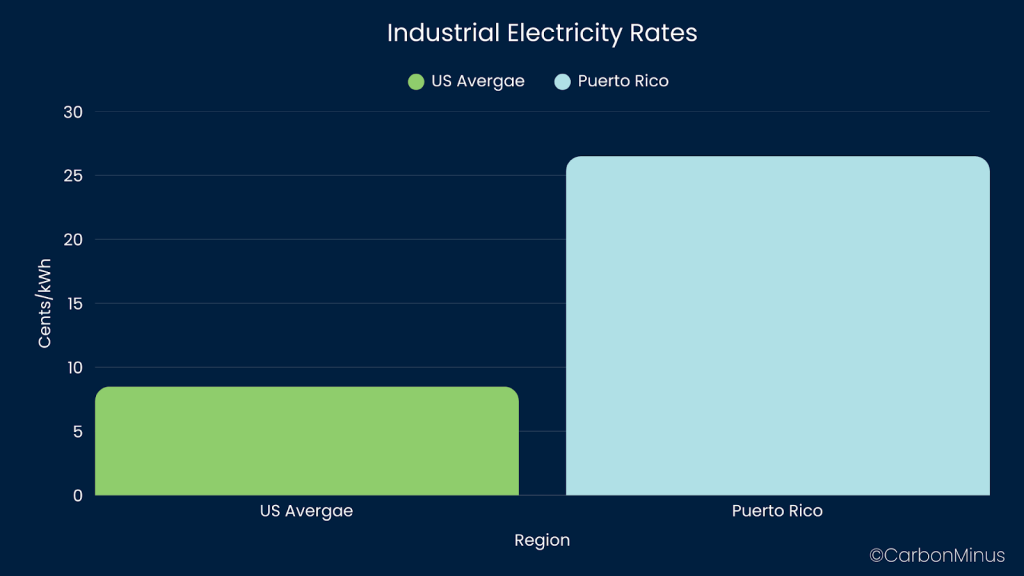

Two manufacturing facilities stand just miles apart in Puerto Rico. Both are pillars of the island’s high-tech manufacturing sector. Both face the same crippling reality: industrial electricity rates that are a staggering 219% higher than the U.S. mainland average.

Industrial Electricity Rates: Puerto Rico vs US Mainland – A 219% Cost Disadvantage

Then, the hurricane hits. The island’s fragile grid collapses, as it has time and time again.

For Factory A, the result is catastrophic. Production lines grind to a halt. Sensitive, multi-million-dollar equipment is damaged by power surges. For weeks, they are dark, bleeding over $2.3 million in lost revenue and repair costs.

But at Factory B, something different happens. The lights don’t even flicker. Production continues, orders are filled, and they post their highest profit margin of the year.

This wasn’t luck. It was the result of one strategic decision, a choice that most manufacturers in Puerto Rico are completely overlooking. What did the leaders at Factory B know that their competitors didn’t? The answer has nothing to do with waiting for the grid to be fixed and everything to do with seizing a hidden advantage buried within the crisis itself.

Puerto Rico’s Manufacturing Energy Crisis: The Crippling Cost of “Business as Usual”

For any Operations Director or CFO in Puerto Rico, the monthly energy bill is a strategic crisis in the making. Let’s be blunt: paying 26.48¢ per kilowatt-hour, while your mainland competitors pay an average of just 8.30¢, is not a sustainable position. This amounts to the 219% cost disadvantage we spoke about earlier that directly attacks your profitability and global competitiveness.

This is also about

For a mid-sized manufacturing facility, this premium can easily translate into an extra $1.5 to $2 million in annual energy spending compared to an identical facility in the mainland US. That’s capital that could be used for R&D, talent acquisition, or market expansion. Instead, it’s simply disappearing into an inefficient and unreliable grid.

That’s the reality of trying to compete with one hand tied behind your back. It forces you on the defensive by dimming lights, cycling air conditioning, and constantly worrying about the next power bill or blackout.

But what if the defensive posture is the very thing holding you back? While most companies are focused on Puerto Rico’s blackout risk mitigation for manufacturers, a select few have discovered how to turn it into their greatest strength.

The question is, how?

Why Smart Money Isn’t Fleeing Puerto Rico. It’s Doubling Down

Here lies the paradox that separates the victims of energy crisis from the victors. While many companies see the island’s energy instability as a reason to scale back, industry leaders are doing the exact opposite.

Consider CooperVision. In the face of this exact energy crisis, they didn’t retreat. They announced a $500 million expansion of their manufacturing facilities in Juana Díaz and Arecibo.

Why would a global leader make such a massive investment in a high-cost, unstable energy market?

Because they understood the secret: Puerto Rico’s manufacturing energy crisis is a forcing function. It forces you to solve the problem of energy independence now, years ahead of your mainland competitors who are still comfortably dependent on a fragile grid.

By investing in their own energy future, they built a competitive moat that insulates them from the very volatility that plagues their rivals.

Their solution? A state-of-the-art 23.3-megawatt Combined Heat and Power (CHP) system. This is a self-contained power plant that allows their facility to operate completely independently from the grid.

For the Operations Director, this means:

- 100% Uptime: Production never stops, even during island-wide blackouts or hurricanes. And that means a major step towards Puerto Rico’s blackout risk mitigation for manufacturers.

- Predictable Costs: They are no longer at the mercy of PREPA or LUMA’s fluctuating rates.

- Enhanced Quality: Stable, high-quality power protects sensitive equipment and ensures product consistency.

For the CFO, the logic is undeniable. The investment in the CHP system was a strategic move to de-risk their entire Puerto Rican operation. It guarantees revenue streams that would otherwise be lost and provides a long-term, predictable cost structure that makes financial planning reliable.

CooperVision solved their energy problem by turning their solution into a weapon. While competitors scramble during the next outage, CooperVision will be capturing market share.

This level of resilience and independence may seem like a luxury only a massive corporation can afford. But there’s another piece to this puzzle, a financial lifeline that puts this power into the hands of many more manufacturers.

A secret that makes the ROI on these projects not just feasible, but incredibly compelling.

Puerto Rico’s Manufacturing Energy Crisis Solutions for Factories

The idea of building your own independent power system might seem like an immense capital expenditure, justifiable only for the largest corporations. But what if you could cut the project cost nearly in half before you even break ground?

This isn’t a hypothetical. It’s the reality made possible by a powerful, yet underutilized, state-sponsored program: the Puerto Rico Green Energy Fund (GEF).

The government of Puerto Rico has allocated $185 million specifically to co-invest in renewable energy projects across the island. For the manufacturing sector, the most critical part of this program is “Tier 2,” designed for industrial-scale projects. This tier offers a game-changing incentive: a rebate of up to 50% of the eligible costs for renewable energy systems between 101 kW and 1 MW.

What This Means for Your Bottom Line

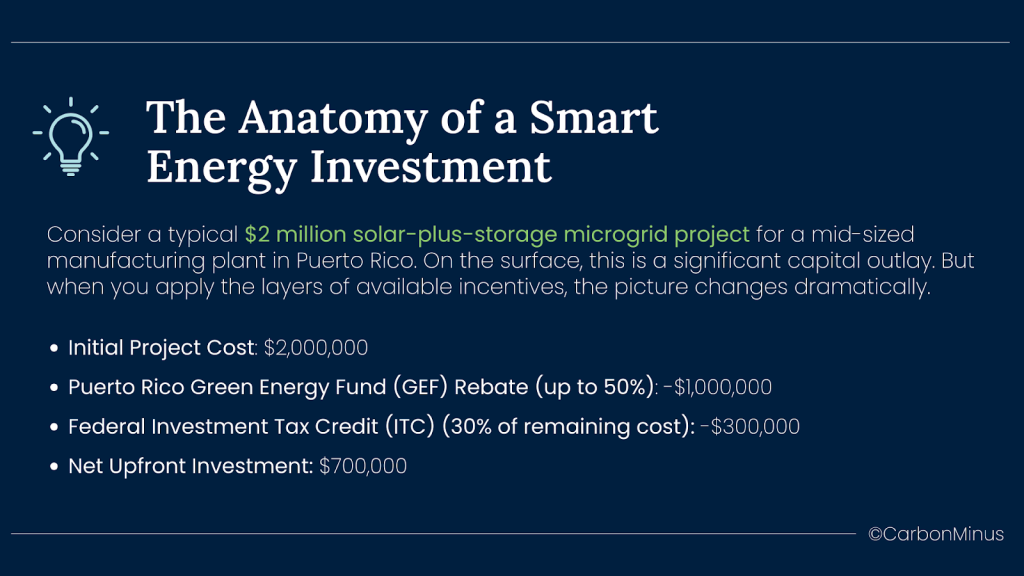

Let’s translate this for the C-Suite. Imagine a comprehensive solar and battery storage project with a price tag of $2 million. For a CFO, approving that expenditure is a major decision with significant risk. But through the Green Energy Fund, that project could receive a rebate of up to $1 million, effectively slashing your initial capital outlay in half.

Suddenly, the ROI calculations transform:

- Payback periods are cut dramatically, often from 5-7 years down to just 2-3 years.

- The internal rate of return (IRR) becomes far more attractive, making the project an easy “yes.”

- The risk profile of the investment is significantly lowered.

This isn’t free money, rather a strategic government co-investment in your resilience and Puerto Rico’s energy future. The process is competitive and requires a robust, well-documented application, but the rewards are immense.

And this is just the beginning. The GEF is part of a much larger ecosystem of incentives. The Puerto Rico Incentives Code (formerly Act 60) further sweetens the deal, offering businesses that generate their own green energy a fixed 4% income tax rate and up to a 75% exemption on property taxes for the equipment. When combined with Federal tax credits, the financial case becomes overwhelmingly positive.

The funds are there. The tax advantages are on the table. The government is actively incentivizing manufacturers to make this shift.

The only question is, what is the right technology to invest in to truly hurricane-proof your bottom line and secure this competitive edge? Just installing solar panels isn’t enough. The key lies in creating a truly intelligent, resilient, and independent energy ecosystem.

Hurricane-Proof Your Bottom Line: The Microgrid Advantage

So, how do you build an energy system that not only survives a Category 5 hurricane but thrives because of it? The answer is intelligently managing the power you generate. The solution is a microgrid: an independent, islandable energy ecosystem for your facility that is the backbone of modern energy resilience.

Look no further than Eaton’s circuit breaker manufacturing plant in Arecibo for a masterclass in microgrid implementation. Faced with the same challenges as every other manufacturer, Eaton partnered with Enel North America to build what is now the largest clean energy microgrid in Puerto Rico.

This isn’t just a few solar panels on the roof. It is a comprehensive system designed for ultimate resilience:

- 5 MW of solar power to generate clean energy during the day.

- 1.1 MW of battery storage to store excess energy and provide instant power when needed.

- Integration with existing on-site generators for multilayered redundancy.

- An intelligent microgrid controller that acts as the “brain,” optimizing all power sources and deciding when to draw from the sun, the battery, or the grid.

Crucially, the entire system is engineered to withstand Category 5 hurricane-force winds, ensuring that when the main grid goes down, Eaton’s facility does not.

The Blueprint for a Resilient Future

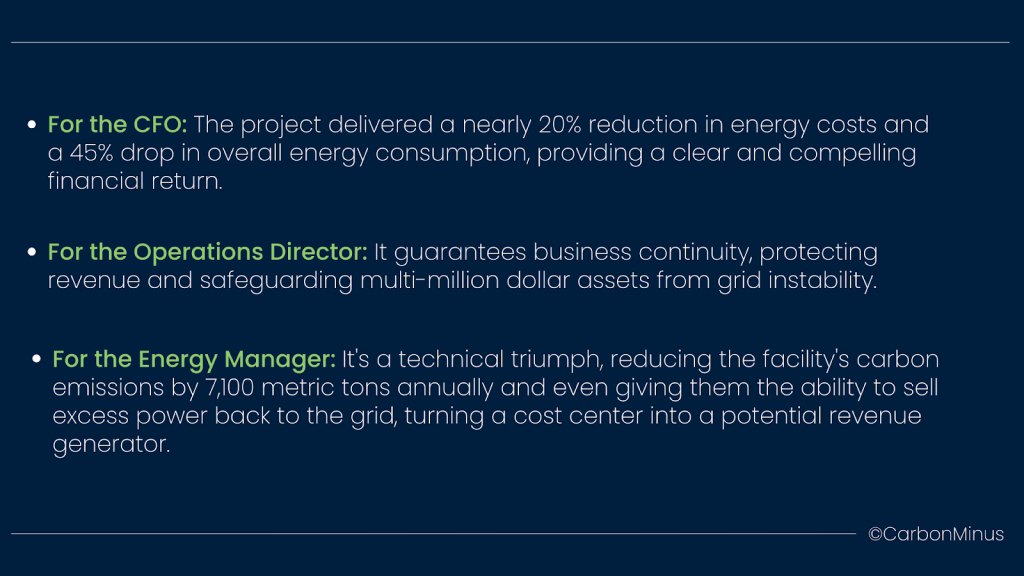

The results of Eaton’s “Everything as a Grid” approach are a blueprint for any forward-thinking manufacturer in Puerto Rico

Eaton and CooperVision prove that energy independence is not a dream. It’s an achievable strategy. They have laid the blueprint. The technology is proven, and the financial incentives are in place. Now, the final step is a clear, actionable plan to get there.

How to Reduce Industrial Electricity Costs in Puerto Rico’s Manufacturing Sector

Understanding the “what” and “why” is essential, but execution is what matters. Transforming your facility from a victim of Puerto Rico’s manufacturing energy crisis into a resilient, cost-efficient leader requires a disciplined, strategic approach.

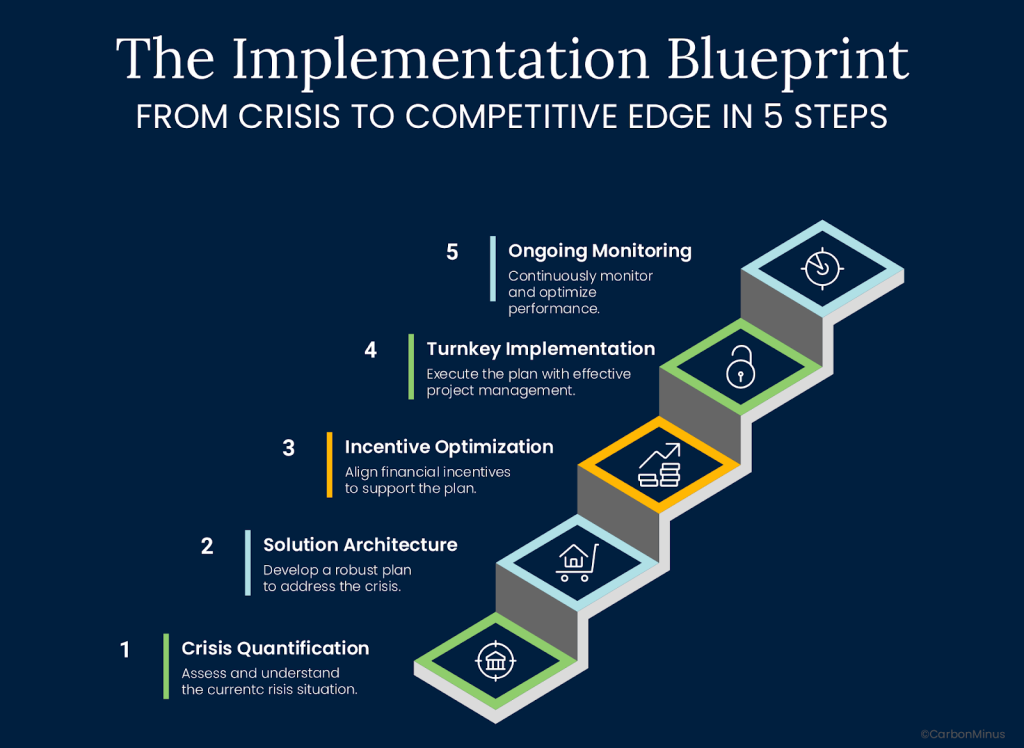

Here is the 5-step blueprint that successful manufacturers follow:

Step 1: Crisis Quantification & Energy Audit

Before you can solve the problem, you must measure it. The answer to how to reduce industrial electricity costs in Puerto Rico’s manufacturing sector starts with a comprehensive energy audit to identify your exact usage patterns, demand peaks, and vulnerabilities.

At CarbonMinus, we go deeper, quantifying the full cost of inaction including lost production from outages, equipment damage, and the opportunity to reduce Puerto Rico’s plant energy spend 20 to 40 percent. This provides the baseline data needed to build a powerful business case for the CFO.

Step 2: Solution Architecture & Resilience Planning

With the data in hand, the next step is to design your microgrid. This involves:

- Right-Sizing Generation: Determining the optimal mix of solar, battery storage, and existing generators to meet your critical loads.

- Intelligent Controls: Selecting a microgrid controller that can seamlessly manage these assets, ensuring you are always using the lowest-cost source of power.

- Hurricane Hardening: Engineering the system from panel mounts to battery enclosures to withstand Category 5 winds and ensure flawless operation during and after a storm.

Step 3: Incentive Optimization & Financial Modeling

This is where the financial case is made concrete. It involves more than just filling out a form for the Green Energy Fund. A true expert will model the complex interplay of local and federal incentives to maximize your financial return. This includes:

- Navigating the competitive Tier 2 application process for the $185M GEF to secure a rebate of up to 50%.

- Leveraging the 4% fixed income tax rate and 75% property tax exemption under the PR Incentives Code.

- Maximizing federal tax credits and depreciation benefits.

This turns a strong project into an undeniable investment.

Step 4: Turnkey Implementation & Project Management

Deploying a multi-megawatt microgrid is a complex undertaking involving permitting, interconnection agreements, construction, and commissioning. An experienced partner manages this entire process, ensuring the project is completed on time and on budget, with minimal disruption to your ongoing operations.

Step 5: Ongoing Monitoring & Performance Optimization

Your energy journey doesn’t end when the system is turned on. The final step is continuous monitoring and optimization. With CarbonMinus’s platform, you get real-time visibility into your energy generation, consumption, and savings.

Our system continuously optimizes performance, ensuring you are always maximizing your ROI and maintaining peak resilience.

This blueprint demystifies the path to energy independence. It’s a proven process that moves your facility from a position of vulnerability to one of strength, control, and long-term competitive advantage.

ROI Reality Check: What the Numbers Actually Look Like

For any C-suite executive, particularly the CFO, the final decision always comes down to the numbers. A technically elegant solution is irrelevant if it doesn’t deliver a strong, quantifiable return on investment.

Let’s break down the real-world financial impact of a strategic microgrid investment, moving beyond hypotheticals to the concrete data that drives decisions.

In this scenario, a robust incentive strategy has already reduced the initial capital required by 65%.

From Capital Cost to Payback Period

Now, let’s look at the operational savings. A well-designed microgrid can cut a facility’s grid dependence by 70–90%, delivering annual energy cost reductions of 20–40%. For a plant with a $1 million electricity bill, even a conservative 25% drop translates to $250,000 saved every year a clear example of how energy costs change equipment investment decisions across facilities.

- Simple Payback Period = Net Investment / Annual Savings

- Payback Period = $700,000 / $250,000 = 2.8 years

Without incentives, the payback period would have been 8 years. With a strategic approach, the investment pays for itself in under 3 years, unlocking positive cash flow for years to come.

The Hidden Financial Benefits

The ROI doesn’t stop there. This analysis doesn’t even include the “hidden” financial benefits that are critical for any operational leader:

- Revenue Protection: The value of avoiding even a single week of lost production during an outage can often exceed the entire cost of the project.

- Equipment Longevity: Clean, stable power from a microgrid reduces wear and tear on sensitive manufacturing equipment, lowering maintenance costs and extending asset life.

- Budget Certainty: It transforms a volatile, unpredictable operating expense into a fixed, predictable one, making financial planning far more accurate.

When you combine rapid payback, sustained long-term savings, and profound risk mitigation, the decision becomes clear. This is no longer an expenditure. It is one of the highest-return investments a manufacturer in Puerto Rico can make today.

Of course. Here are the concluding sections of the blog: the Conclusion and the FAQs. These are designed to summarize the core argument, reinforce the call to action, and address any lingering questions the reader might have.

The Choice Is Yours: Victim or Victor?

We began with the story of two factories facing the same crisis. One was plunged into darkness, suffering millions in losses. The other continued to operate, turning the crisis into its most profitable quarter.

The difference was never about luck. It was about foresight and recognizing that the immense challenge of Puerto Rico’s energy landscape also presented a once-in-a-generation opportunity to build a more resilient, independent, and ultimately more profitable business.

The path forged by leaders like CooperVision and Eaton is now clear. The technology is proven. The financial incentives, from the $185M Green Energy Fund to powerful tax advantages, have made the business case undeniable.

The question is no longer “if” but “when.” Every day you remain tethered to an unstable and expensive grid is a day you are actively choosing to be vulnerable. You are leaving money on the table, putting your production at risk, and falling a step behind competitors who are making the leap.

The choice is now in your hands. Will your facility be the next Factory A, a victim of the next inevitable blackout? Or will you join the ranks of Factory B, seizing the opportunity to turn crisis into a competitive weapon and securing your future in Puerto Rico for decades to come?

Your journey to energy independence starts with a single step. Don’t wait for the next outage to force your hand. Take control of your energy future today.

Know more at www.carbonminus.com. We are experienced in helping companies save costs drastically in energy-intensive industries without affecting operations – https://youtu.be/uk9dUWPhYQ0

FAQs

We are a smaller manufacturing facility. Is a microgrid still a viable option for us?

Absolutely. Microgrids are scalable. While large corporations like CooperVision have implemented massive systems, the same principles apply to smaller operations. The Green Energy Fund’s “Tier 1” is specifically designed for smaller projects (up to 100 kW) and offers rebates on a first-come, first-served basis, making it even easier for smaller facilities to get started.

How long does it take to implement a microgrid project?

A typical project, from initial assessment to full commissioning, can take anywhere from 9 to 18 months. The timeline is influenced by permitting, equipment availability, and the complexity of the installation. Starting the process now ensures you are prepared for future challenges.

What happens if our microgrid needs maintenance? Do we have to become energy experts?

Not at all. A key component of a modern energy solution is a comprehensive service and maintenance agreement. At CarbonMinus, we provide ongoing monitoring, preventative maintenance, and rapid-response support to ensure your system operates at peak performance, allowing you to focus on your core business.

Can we really operate completely independently from the grid?

Yes. A properly designed microgrid with sufficient solar generation and battery storage can allow your facility to operate in “island mode” indefinitely, as long as you have a fuel source for backup generators if needed for extended periods. During normal times, you can remain connected to the grid to sell back excess power or draw from it strategically, giving you the best of both worlds.

The incentive application process seems complex. Can you help with that?

Navigating the web of local and federal incentives is one of the most critical and challenging parts of the process. Our team at CarbonMinus has deep expertise in this area. We manage the entire application process on your behalf to ensure you maximize every available dollar, from the GEF rebates to federal tax credits.

References

- https://siteselection.com/leading-contact-lens-manufacturer-announces-multiple-projects-in-puerto-rico/

- https://www.coopercos.com/news-articles/coopervision-puerto-rico-increases-resiliency-through-combined-heat-and-power-system/

- https://www.prgef.com

- https://www.grantthornton.pr/insights/kevane-grant-thornton/articles/2-28-2025-tax-insight-tax-breaks-and-incentives-for-businesses-adopting-sustainable-and-eco-friendly-practices/

- https://www.ess-news.com/2024/08/29/u-s-doe-allocates-funding-for-community-solar-battery-storage-in-puerto-rico/

- https://www.energy.gov/articles/doe-announces-intent-fund-solar-and-battery-storage-community-healthcare-facilities-and

- https://www.energy.gov/sites/default/files/2024-09/Puerto-Rico-Energy-Resilience-Fund-Webinar-Overview-Slides-English-508.pdf

- https://nuevaenergia.pr.gov/en/

- https://www.fundacionborincana.org/en/green-energy-incentives-in-puerto-rico-opportunities-for-local-businesses/

- https://energia.pr.gov/wp-content/uploads/sites/7/2025/08/20250814-MI20220001-Motion-to-Subm-FY2025-Q4-Consolidated-Trans-Period.pdf

- https://grupocne.org/2024/05/21/lets-get-going-next-steps-in-puerto-ricos-energy-transformation/

- https://energia.pr.gov/wp-content/uploads/sites/7/2025/07/20250722-MI20220001-Motion-to-Subm-Amended-Energy-Efficiency-1.pdf

- https://solarquarter.com/2024/07/23/u-s-doe-launches-325-million-program-to-enhance-energy-resilience-in-puerto-rico/

- https://www.energy.gov/eere/solar/federal-tax-credits-solar-manufacturers

- https://taxsummaries.pwc.com/puerto-rico/corporate/tax-credits-and-incentives

- https://www.epa.gov/greenhouse-gas-reduction-fund/frequent-questions-about-solar-all

- https://www.cleanenergyauthority.com/solar-rebates-and-incentives/puerto-rico

- https://www.energy.gov/gdo/puerto-rico-grid-recovery-and-modernization

- https://energia.pr.gov/wp-content/uploads/sites/7/2025/07/20250703-AP20230003-Motion-Submitting-Rate-Review-Petition.pdf

- https://programs.dsireusa.org/system/program/detail/3185

- https://finance-commerce.com/2025/05/puerto-rico-manufacturing-tariff-opportunity/

- https://incentivosolar.pr.gov/en/