Key Takeaways

- Annual carbon audits miss real-time operational waste.

- AI tools can’t optimize emissions without live data.

- CBAM and ESG frameworks demand timestamped reporting.

- Real-time systems shift carbon from lagging indicator to live decision point.

- Competitive advantage now lies in carbon visibility—hour by hour.

Most plants don’t have an emissions problem.

They have a time problem.

Annual carbon audits don’t drive performance. They just document it—after the fact, when it’s too late to intervene. If emissions were an actual fire, most industrial systems are still reading the smoke detector once a year.

This lag doesn’t just slow down decarbonization. It kills it.

By the time you identify a spike in fuel consumption or fugitive emissions, the damage is already baked into your compliance report—and your carbon costs. While the market and regulators move in real time, your plant is reacting on a 12-month delay.

That gap between action and insight?

It’s where energy gets wasted. Targets get missed. Carbon credit opportunities disappear.

Time isn’t just a reporting detail anymore. It’s a competitive liability.

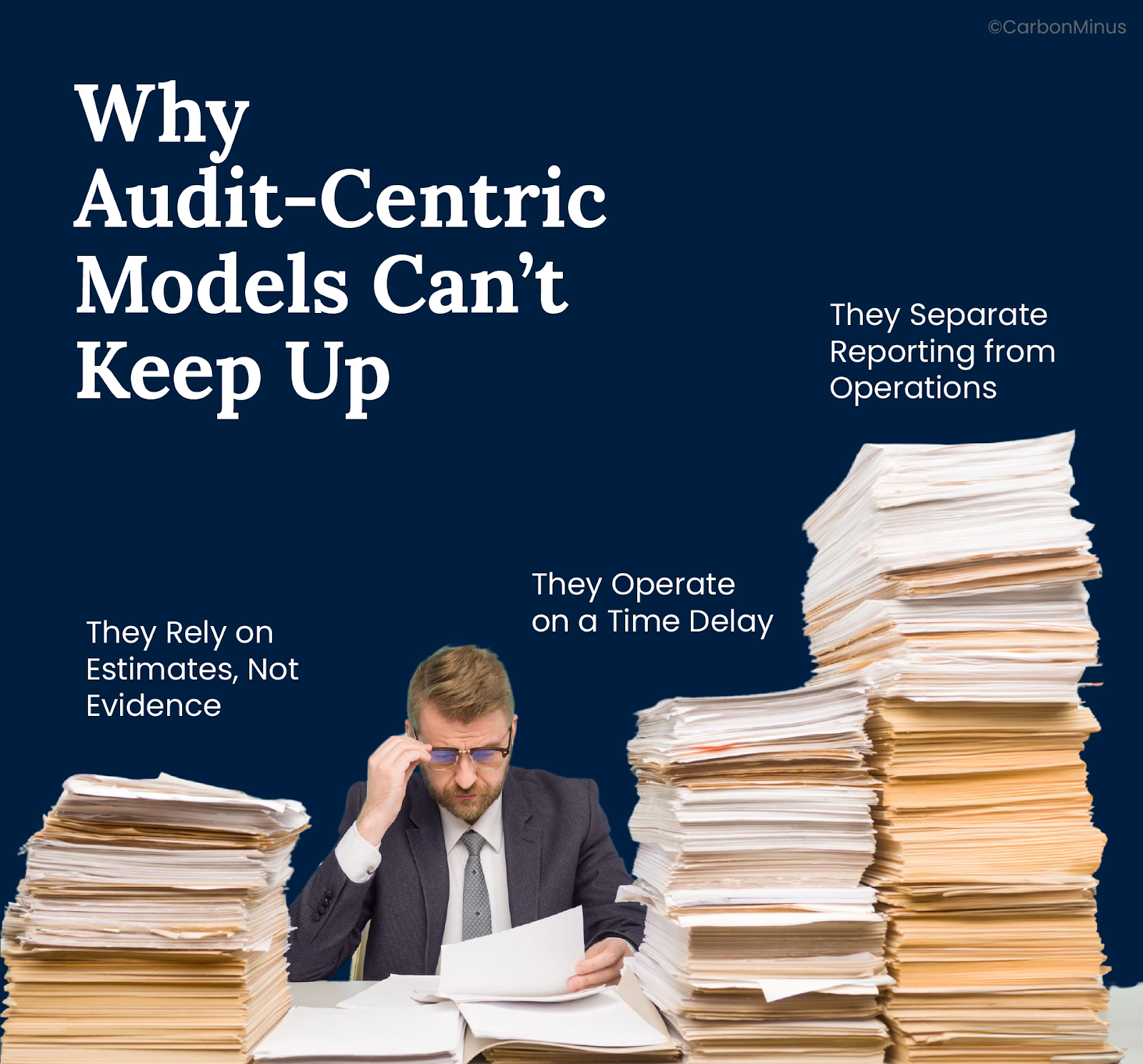

Why Audit-Centric Models Can’t Keep Up

Most industrial carbon strategies still run like it’s 2005:

Spreadsheets. Quarterly reviews. Annual compliance deadlines.

This model wasn’t built to mislead.

It was built when carbon was a cost center—not a compliance metric, a market price, and a reputational risk rolled into one.

But in today’s landscape, audit-led approaches fail on three fronts:

1. They Rely on Estimates, Not Evidence

Manual reporting often blends assumptions, outdated emission factors, and averaged energy data. That doesn’t hold up when regulators, or buyers, want timestamped proof tied to real output.

2. They Operate on a Time Delay

By the time anomalies show up in reports, the opportunity to adjust has passed. Energy waste becomes locked-in carbon. A leak becomes a liability. You don’t get to intervene—you only get to explain.

3. They Separate Reporting from Operations

Carbon remains a box to check, handled by sustainability teams while the real levers sit with plant ops, maintenance, and procurement. That split means insights don’t translate into action fast enough to matter.

In short:

- Audits show what happened.

- But decarbonization depends on what’s happening now.

The CBAM Wake-Up Call

The Carbon Border Adjustment Mechanism (CBAM) isn’t just a carbon tax.

It’s a forensic exam of your emissions data—line by line, shipment by shipment.

Starting now, exporters to the EU must provide product-level emissions figures. Not estimates. Not annual averages. Auditable, primary data tied to actual production.

If your plant can’t verify emissions in real time, your goods could face penalties at the border even if your total footprint is “compliant.”

Why It Matters Beyond the EU

CBAM is the blueprint. Other regions are watching.

Buyers are already asking for carbon transparency in tenders. Investors want granularity in ESG disclosures. Suppliers with missing data risk being priced out of green supply chains even if they hit every internal KPI.

And make no mistake: CBAM won’t stop with cement, steel, and aluminium. Chemicals, textiles, and machinery are already under review for future inclusion.

What CBAM Actually Signals

- Retrospective reporting is over

- Third-party audits aren’t enough

- Continuous data is now the default

You’re no longer competing on price or quality alone.

You’re competing on carbon, and the burden of proof is shifting upstream.

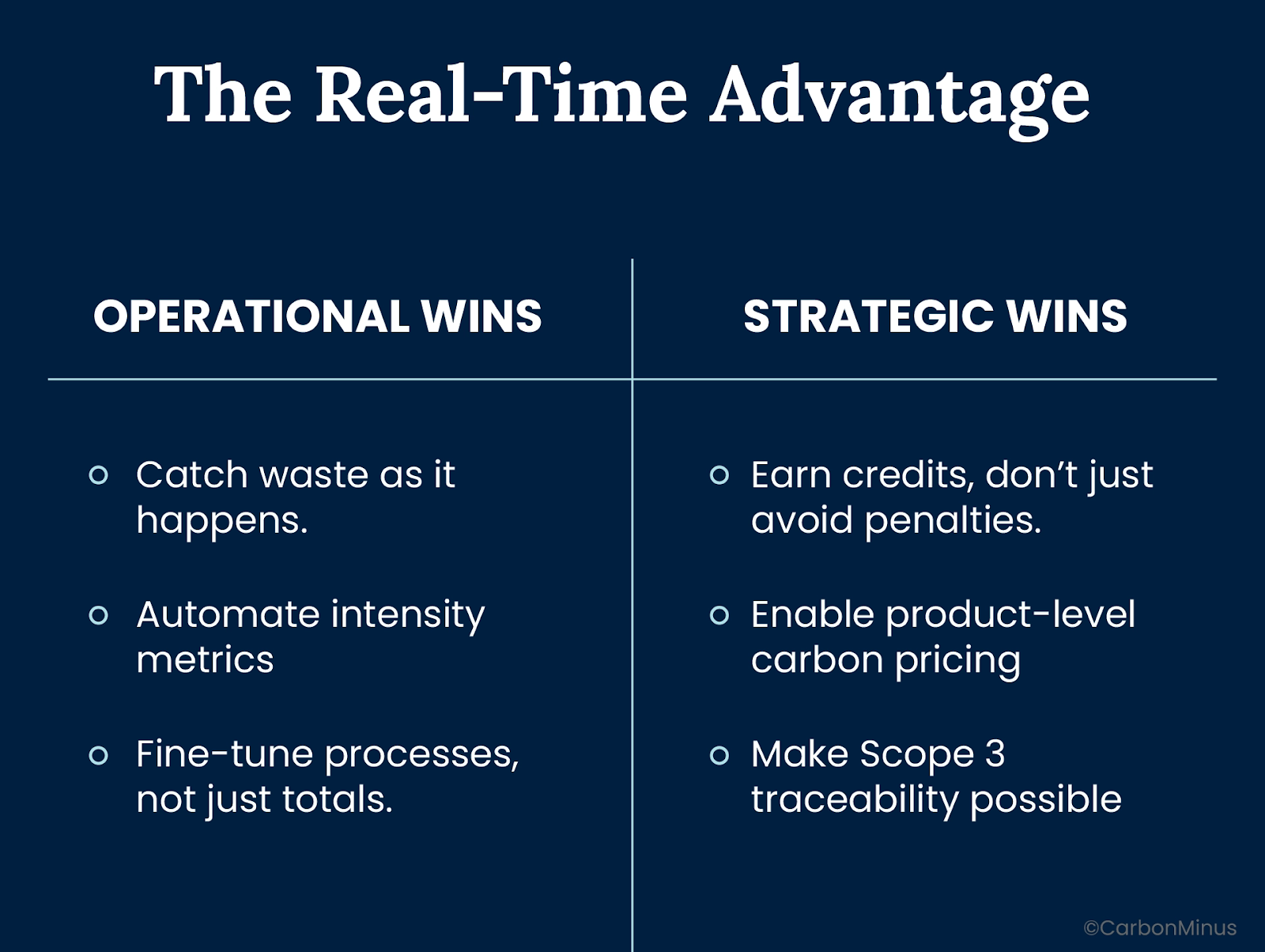

The Real-Time Advantage

Decarbonization isn’t just about targets. It’s about timing. And in industrial systems, timing is everything.

When emissions data is real-time, it stops being a cost report and becomes a control signal.

Operational Wins

- Catch waste as it happens. Real-time energy and emissions tracking lets teams respond before overconsumption locks in.

- Automate intensity metrics. Tie fuel, steam, and electricity consumption directly to unit-level output—hour by hour, not just quarterly.

- Fine-tune processes, not just totals. Track anomalies in combustion, batch load efficiency, or process flow that create silent spikes in Scope 1 and 2.

Strategic Wins

- Earn credits, don’t just avoid penalties. The faster you surface carbon savings, the faster you can monetize them in schemes like CCTS.

- Enable product-level carbon pricing. Real-time data supports carbon-intensity tracking per batch, per line, per SKU.

- Make Scope 3 traceability possible. Live Scope 1 and 2 data feeds directly into downstream buyer frameworks.

When emissions are tracked live, carbon stops being a reporting burden and becomes a lever for performance, compliance, and market advantage.

You can’t cut what you can’t see in time.

The AI-CBAM Collision Course

Everyone’s talking about AI in industrial decarbonization.

But here’s what they’re not saying: AI can’t optimize what it can’t see.

You can build the smartest model on paper but if it’s running on stale, static, or proxy data, you’re just automating the wrong decisions faster.

Where This Breaks Down

Take a cement kiln. An AI model might dial back temperature to save fuel. Sounds great—until you realize the trade-off pushed carbon intensity beyond CBAM thresholds for that batch.

Or consider a compressor. A predictive system might reduce runtime, but without emissions tagging, it can’t account for a fugitive refrigerant leak that quietly doubles your Scope 1 footprint.

What Real-Time Data Actually Enables

- Adjust fuel mix or process settings based on live carbon readings—not just energy use

- Spot when you’re headed toward an emissions breach before a single non-compliant batch leaves the line

- Weigh energy savings against carbon costs in real time—so optimization doesn’t backfire under CBAM or internal ESG targets

Without current emissions data, AI systems can only guess.

With it, they can act with precision that reflects not just efficiency, but carbon accuracy.

Beyond Compliance: Real-Time as a Competitive Edge

Real-time carbon data isn’t just a compliance tool.

It’s the foundation of competitive advantage for the companies serious about staying ahead.

Prove ESG performance—instantly.

Live dashboards show investors where your carbon stands now, not where it was 12 months ago. That’s credibility you can’t fake.

Price carbon into decisions.

When emissions are visible at the unit level, you can factor them into product costing, procurement strategy, and production planning just like fuel or labor.

Preempt regulation.

Regulatory expectations are rising fast. When your reporting already matches what BRSR, ISO 14064, or CSRD will demand next year, you don’t have to scramble to keep up, you’re already there.

Carbon-tracked trade is no longer theory. It’s here.

CBAM is already live. Other regions are watching. And downstream buyers are asking for emission records at the invoice level. If you don’t have timestamped data, you’re not in the game.

Negotiate better procurement contracts.

Buyers are scoring suppliers on carbon. Real-time data gives you leverage—because you’re not just promising sustainability, you’re proving it.

Avoid supply chain delays.

When you can’t produce emissions documentation on demand, your product stalls. Real-time systems keep you audit-ready—batch by batch, shipment by shipment.

Carbon visibility isn’t a checkbox anymore. It’s a source of speed, certainty, and strategic control.

The Future Is Timestamped

The shift is already underway. From compliance officers to CFOs, from regulators to trade partners, everyone wants the same thing:

Proof.

Not averages. Not estimates. But proof.

That proof has a timestamp. And if your emissions data doesn’t have one, your claims won’t hold up for audits, for ESG reports, or for border checks.

This Isn’t a Tech Problem

The tools exist. The infrastructure exists.

What’s missing is the shift in mindset from reporting lag to operational visibility.

Real-time carbon data isn’t just a future trend. It’s the minimum requirement for staying relevant in an emissions-priced economy.

So if you’re still relying on quarterly audits and backdated spreadsheets, here’s the question:

How long can you afford to manage carbon blind?

FAQs

Is real-time carbon tracking too complex for legacy plants?

It’s rarely the hardware that holds things back. Most plants already collect useful data—they just don’t use it for emissions. The hard part is getting teams to treat carbon like any other performance metric: tracked, tagged, and tied to output.

We already track energy in real time. Isn’t that enough?

Not quite. Two plants with the same energy use can have very different emissions—depending on what fuels them, when they run, and how well they manage losses. Without carbon-specific data, you’re only seeing half the picture.

How does real-time data help with audits?

It gives you a live record—so you’re not digging through months-old spreadsheets when the auditor shows up. Every reading has a time and a source. That means less guesswork, fewer gaps, and no scrambling to explain where a number came from.

What types of industries need this most?

The pressure’s highest in sectors with heavy fuel use or regulatory scrutiny—like cement, steel, or chemicals. But it’s spreading fast. Any exporter, or anyone in a Scope 3-heavy value chain, is next in line.

What’s the business case for investing in real-time carbon tools?

Start with what it helps you avoid: rushed audits, reporting errors, and blocked shipments. Then look at what it opens up—green financing, faster contract approvals, and fewer last-minute surprises during ESG reviews. That’s ROI your CFO understands.