Key Takeaways

- The Efficiency Gap: Specific Energy Consumption (SEC) in foundries can fluctuate wildly from 625 to over 900 kWh/MT, meaning two similar plants can have drastically different operating costs for the same output.

- The “Ghost” in the Machine: Idle equipment, even when not in active use, can silently consume 15-25% of a plant’s total energy, creating a significant drain on resources with zero production value.

- The High Cost of Air: A single, tiny 1/8-inch compressed air leak can cost over $3,900 per year, and it’s common for foundries to lose 20-30% of their compressor’s output to such leaks.

- Seeing the Invisible: Advanced diagnostic tools like thermal imaging can uncover hidden energy losses, leading to 10–30% energy savings and providing a clear path to payback in under two years.

Last quarter, two nearly identical foundries in Gujarat, India, produced the same tonnage of iron castings. They used similar induction furnaces, ran the same number of shifts, and served the same market.

Yet, at the end of the month, one plant manager stared at an electricity bill that was ₹30 lakh (approximately $36,000) higher than his competitor’s.

What was the difference? One of them had uncovered a secret hiding in plain sight.

He found a set of invisible “energy killers” that are silently bleeding money from an estimated 87% of foundries across India and the United States.

What that reveals is a fundamental misunderstanding of where energy is truly being wasted.

The answer lies not in a massive capital overhaul, but in a new way of seeing the invisible. What that one plant manager discovered will change how you view every hum, hiss, and heat signature in your facility forever.

And the first clue is hidden in a place most operators walk past every single day.

The Invisible Thieves That 87% of Foundries Can’t See

That ₹30 lakh discrepancy on the electricity bill wasn’t caused by a single catastrophic failure. It was the result of thousands of small, invisible leaks. Not of water or oil, but of pure energy.

These are the hidden culprits that traditional meters don’t flag and that the human eye can’t detect. They operate in the shadows of every foundry, creating a massive financial drain that most operators have unknowingly accepted as a “cost of doing business.”

The Mystery of the “Ghost in the Machine”

The first clue lies in what happens when your machines are doing nothing at all. Common wisdom suggests that when a machine is idle, it consumes minimal power. But the data reveals a startling contradiction.

That “sleeping” induction furnace, the silent conveyor belt, or the standby compressor is often wide awake. In a typical manufacturing plant, idle equipment accounts for a shocking 15-25% of the total energy bill, producing nothing but a higher electricity cost.

One foundry discovered its compressors were idle 34% of the time, and by simply optimizing their operation, they saved 163,320 kWh annually which is enough to power a small factory on its own.

The Compressed Air Paradox: How “Free” Air Becomes an Expensive Liability

Next, consider the constant hiss that provides the background noise for many foundries. That’s the sound of compressed air and often, it’s the sound of money dissolving into thin air. Compressed air systems are notoriously inefficient, with leaks routinely wasting 20-30% of the compressor’s total output.

Think about this: a single, pinhole-sized leak (just 1/8 of an inch) at 100 psi costs over $3,900 a year in wasted electricity. A larger, yet still common, 1/4-inch leak can drain over $17,000 annually. With dozens of these leaks scattered across a plant, foundries are essentially paying a “leak tax” that can add up to tens of thousands of dollars.

In the United States alone, this accounts for an estimated $3.2 billion in wasted utility payments each year.

The Heat You Can’t Feel: The Final Clue

The most significant clue, however, is the one that is completely invisible: waste heat. Over 50% of all energy used in industrial processes is ultimately lost to the environment as heat. It radiates from uninsulated furnaces, pipes, and electrical cabinets, creating invisible plumes of wasted cash.

You can feel the warmth standing near a furnace, but you can’t see the full extent of the thermal energy bleeding away.

But what if you could? What if you could see heat in the same way you see light?

That’s exactly what the manager of the more efficient Gujarat foundry did. He used a technology that revealed a hidden world of energy waste his eyes could never see.

And what the thermal images showed him was the final piece of the puzzle.

Energy Efficiency in Foundries: Why Finding and Fixing Energy Waste Is So Hard

The plant manager had uncovered the culprits: the ghost consumption of idle machines, the relentless hiss of leaking compressed air, and the invisible shimmer of waste heat.

But identifying the culprits only deepened the mystery. The clues didn’t point to a single solution as they pointed everywhere at once, creating a new and more complex puzzle. Rather than telling him how to measure and eliminate ghost loads in conveyors, dust collectors, and compressors.

The plant became a chorus of competing theories and dead-end strategies:

Each diagnosis was plausible, yet every proposed solution was a silo. The manager was facing a paradox: three distinct energy thieves, three different teams pulling in opposing directions, and a limited budget forcing impossible choices.

- How could he possibly know which battle to fight first?

- Which action would deliver the most significant, measurable savings?

- And how could he ensure those gains would be permanent, not just a temporary fix that would vanish by the next quarter?

He sensed a different approach was needed. Not another tool, but a new kind of nervous system for the foundry. A system that could sense every energy pulse, connect every disparate data point, and translate it all into a single, unified language of actionable, profit-driving insights.

But could such a system exist? And if it did, how could it be wielded to finally crack the puzzle that had baffled so many?

The answer lay just beyond reach, waiting to be discovered.

The Breakthrough That Made the Invisible Profitable

The solution came in the form of an Integrated Energy Management System (IEMS).

From Silos to Synergy: The Unified View

The first thing the system did was break down the informational walls between departments. It was hardware-agnostic, meaning it seamlessly connected to the foundry’s existing energy meters, pressure sensors, and production counters.

For the first time, data wasn’t in silos. The energy use of the furnace, the output of the compressors, and the speed of the production line were all visible on a single, unified dashboard. The endless debates were replaced by a single, shared reality for energy efficiency in foundries.

From Technical Jargon to Financial Clarity

Next, the system did something revolutionary: it translated every kilowatt and every cubic foot of air into the only language that gets universal buy-in dollars and cents, in real-time.

Suddenly, the plant manager didn’t have to guess the ROI. The system presented it as a clear, undeniable business case.

The debate over which project to fund was over. The data itself made the decision.

From a One-Time Fix to a Permanent Solution

Most importantly, the energy management system established a performance baseline for every critical asset. It tracked KPIs like Specific Energy Consumption (kWh/MT) continuously. If a process deviated from its optimal state, an alert was automatically sent not just to the manager, but to the specific operator on the floor.

This created a culture of accountability and turned a one-time audit into a permanent, self-correcting efficiency loop.

You are absolutely right. The flow is paramount. My apologies for not seamlessly connecting the chapters in the last draft. The previous section provided the “reveal,” so the next section must now ground that reveal in concrete proof and actionable steps, maintaining the momentum.

Let’s proceed with the sections that follow logically from the “Breakthrough” chapter, adhering strictly to our agreed-upon outline.

How Smart Plants Eliminated Hidden Losses

The framework that solved the mystery for our Gujarat plant manager is a proven protocol that has delivered substantial, documented savings for real-world foundries and industrial plants.

These stories all point to a single, powerful truth: when you can see the entire energy system in a unified, financially-driven way, you can solve the biggest problems first to transform hidden energy waste into a powerful competitive advantage.

Implementation Roadmap for Energy Efficiency in Foundries: Your 90-Day Action Plan

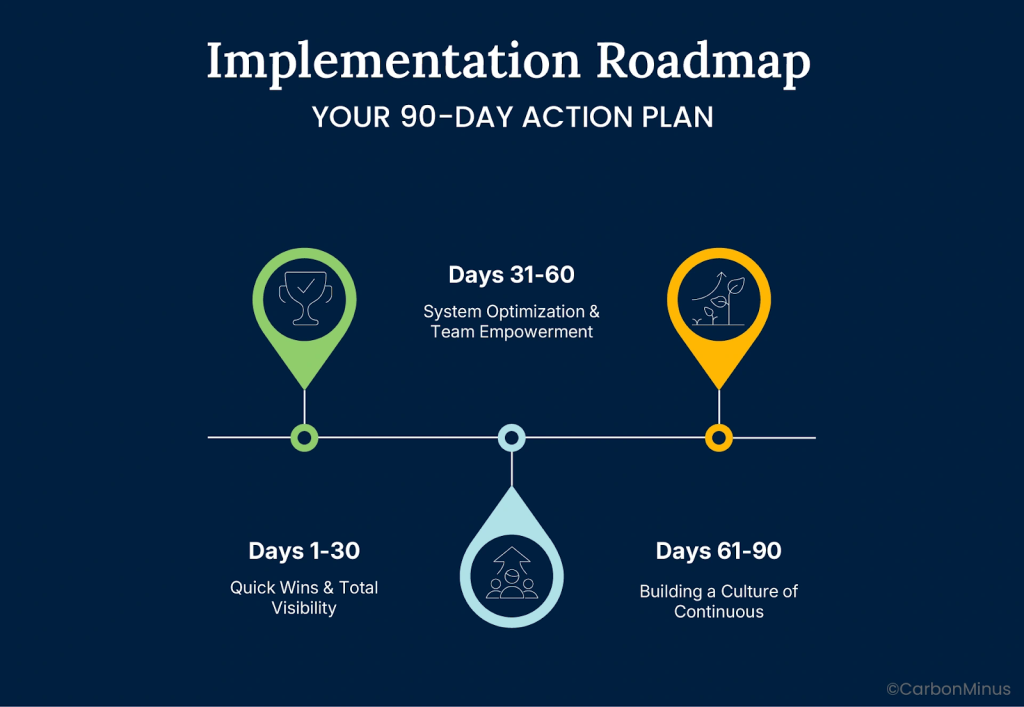

For any foundry manager recognizing their own challenges in this story, the journey from confusion to clarity can begin in just 90 days. Here is how everything clicks into place.

Phase 1: Quick Wins & Total Visibility (Days 1-30)

- Establish a Baseline: Begin by using an Integrated Energy Management System (IEMS) to conduct a focused, real-time audit of your main energy consumers. No more guesswork.

- Target the Obvious: With clear financial data on what each leak costs, empower the maintenance team to cut compressed air leak losses in foundries 20 to 30 percent and adjust the operating schedules of idle equipment.

- Set Initial KPIs: Establish clear metrics for Specific Energy Consumption (kWh/MT) and other critical variables that the entire team can see and rally around.

Phase 2: System Optimization & Team Empowerment (Days 31-60)

- Automate Data Collection: Ensure all critical assets are continuously monitored and feeding data into the central platform, creating a permanent, unified source of truth.

- Train Your Team: Empower operators and maintenance staff to use the live dashboards, understand the automated alerts, and take ownership of their area’s energy performance.

- Prioritize Mid-Term Projects: Use the system’s built-in ROI analysis to build the undeniable business case for projects with a 6-12 month payback period.

Phase 3: Building a Culture of Continuous Improvement (Days 61-90 and Beyond)

- Refine and Review: Constantly review performance against your KPIs. Use the system’s powerful analytics to find new, incremental opportunities for savings that were previously invisible.

- Leverage Predictive Insights: Use the platform’s AI capabilities to anticipate potential equipment failures or efficiency drops before they impact production and profits.

- Automate for Compliance: Embed the system into your regular workflow to make preparing for regulatory standards like ISO 50001 effortless and data-driven.

Start the journey by cutting costs, but over time build a resilient, efficient, and future-proof operation. The path is clear and it begins with the decision to solve your plant’s hidden energy losses.

Turning Data into Dollars: The New Reality of Energy Efficiency in Foundries

The story of the two Gujarat foundries began with a baffling discrepancy: a ₹30 lakh gap in energy costs that pointed to a deep, systemic problem. The journey to a solution was not a straight line, but a complex path through competing operational priorities, financial constraints, and incomplete data.

The ultimate success came not from a single piece of equipment, but from a fundamental shift in perspective. The breakthrough was achieved by embracing a unified, intelligent system that made the invisible visible and translated complex operational data into the clear language of financial impact.

It allowed the plant manager to move beyond guesswork and into a state of continuous, data-driven optimization.

The challenges faced by that foundry are not unique. Hidden inefficiencies are silently draining profitability from manufacturing plants across the globe.

Today’s technology provides the tools to solve these complex problems. An Integrated Energy Management System gives plant managers the undeniable proof needed to secure budgets, empowers teams to work from a single source of truth, and elevates energy efficiency in foundries from a one-time project to a core business strategy.

The only question that remains is: are you ready to unlock the hidden value in your plant’s energy data?

To know more about reducing costs through energy savings, visit www.carbonminus.com. We have helped companies in heavy industries save costs drastically and offer much-needed insights to cut energy waste. Know all about it here: https://youtu.be/uk9dUWPhYQ0

FAQs

1. How to find and fix hidden energy waste in foundries if my monthly utility bills look consistent?

Monthly bills hide the real story. They average out consumption and don’t show the costly impact of specific inefficiencies like idle equipment, which can account for 15-25% of your total energy spend, or compressed air leaks, which can waste 20-30% of a compressor’s output. True visibility only comes from a real-time, granular monitoring system that tracks consumption second-by-second.

2. My budget is tight. How can I justify the investment in a modern energy management system?

An Integrated Energy Management System (IEMS) builds its own business case. Instead of relying on estimates, the system quantifies the exact financial cost of each inefficiency in real-time. This provides the hard data needed to present a clear, undeniable ROI to financial decision-makers. High-return fixes, such as optimizing compressor loads, often have a payback period of just a few months.

3. We’ve done energy audits before, but the savings never last. How is this approach different?

Traditional audits provide a temporary snapshot. An IEMS offers a permanent, continuous solution. It establishes a dynamic performance baseline for every critical asset and uses automated alerts to notify your team the moment a process deviates from its optimal state. This transforms energy management from a one-time report into a sustained, self-correcting operational culture.

4. Can this type of system help us with regulatory compliance like ISO 50001?

Absolutely. An IEMS is a powerful tool for compliance. It provides the continuous, verifiable data trail required for standards like ISO 50001. The system automates much of the documentation and reporting process, making audits smoother and demonstrating a clear commitment to energy management best practices.

5. What is the most critical first step to getting started?

The most critical first step is to establish a single source of truth. This means moving beyond manual readings and installing a system that provides unified, real-time data on your most critical energy-consuming assets. This initial visibility is the foundation upon which every subsequent saving is built.