A groundbreaking new cancer drug is developed, offering hope to millions. It goes through years of research, rigorous clinical trials, and complex manufacturing before reaching the hands of patients.

The world celebrates a medical breakthrough, but behind the scenes, another story unfolds.

For every life-saving drug produced, large amounts of water, energy, and chemicals are consumed.

Waste is generated, emissions are released, and supply chains stretch across continents. The same industry that improves global health also has an environmental footprint that is rarely discussed.

Pharmaceutical companies are making huge strides in innovation, but the challenge now is ensuring that these advancements don’t come at the cost of sustainability.

A High-Impact Industry Facing a New Challenge

The pharmaceutical sector is one of the most resource-intensive industries. Not because companies aren’t trying to be sustainable, but because drug manufacturing is inherently complex.

1. High Energy Demand – Many pharmaceutical processes require temperature-controlled environments, high-powered machinery, and 24/7 operations, leading to a significant carbon footprint.

2. Waste & Water Concerns – The production of active pharmaceutical ingredients (APIs) involves chemical solvents and byproducts that can end up in wastewater systems, affecting marine ecosystems and public health.

3. Global Supply Chains – The industry’s reliance on multiple suppliers, long-distance transportation, and cold-chain logistics makes it difficult to track and reduce emissions effectively.

Companies are increasingly investing in green initiatives, but the traditional approach to sustainability still relies on periodic audits, manual tracking, and reactive compliance.

The problem? That’s not enough anymore.

For companies still using traditional compliance models, financial and operational challenges loom in the near future. Failing to meet environmental targets is a business risk that can lead to higher costs, reputational damage, and competitive disadvantages.

The Path Forward: Can AI Revolutionize Pharma’s Sustainability Efforts?

As sustainability regulations become more complex, companies need smarter, data-driven solutions, and AI is emerging as a game-changer in this space.

In this blog, we’ll explore:

1. Why current compliance and waste management strategies aren’t enough.

2. How AI can provide real-time monitoring of emissions, wastewater, and supply chain inefficiencies.

3. How predictive analytics can optimize chemical usage and minimize waste before it happens.

4. How AI-powered energy management systems can improve efficiency while reducing operational costs.

Let’s dive in.

Big Pharma’s Environmental Burden: A Crisis Hiding in Plain Sight

For years, the conversation around industrial pollution has focused on oil, gas, and manufacturing, while the pharma industry has largely flown under the radar.

The truth? Big Pharma’s carbon footprint rivals some of the most emissions-heavy industries in the world.

Pharmaceutical waste, energy consumption, and inefficient supply chains contribute significantly to the industry’s environmental impact.

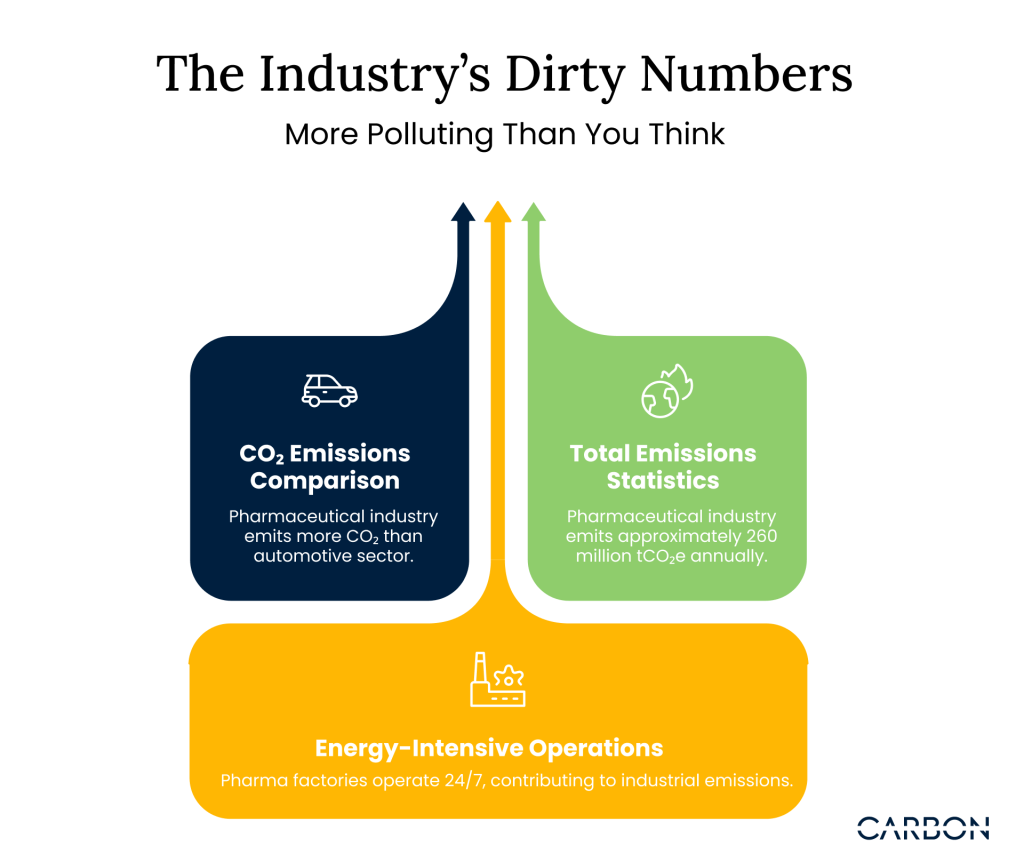

The Industry’s Dirty Numbers: More Polluting Than You Think

The pharmaceutical sector is not only resource-intensive, but its emissions far exceed what most people expect.

1. The global pharmaceutical industry emits more CO₂ than the automotive sector—a shocking reality for an industry focused on health.

2. The entire pharmaceutical industry emits around 260 million tCO₂e—a statistic that raises concerns about how sustainable current practices really are. [1]

3. Many pharma factories operate 24/7, using energy-intensive processes that require continuous heating, cooling, and chemical processing, making them major contributors to industrial emissions.

And while carbon emissions are a serious concern, they are just one part of the problem.

Beyond CO₂: The Hidden Waste Problem

Pharmaceutical manufacturing generates various types of waste, many of which have long-term environmental consequences.

Toxic Wastewater: When Medicine Becomes a Pollutant

Pharmaceutical factories release solvents, chemicals, and active pharmaceutical ingredients (APIs) into water systems, a growing issue in countries with less stringent waste disposal regulations.

1. Traces of antibiotics, hormones, and painkillers have been found in rivers and drinking water supplies worldwide.

2. This contamination disrupts aquatic ecosystems and is contributing to antimicrobial resistance (AMR)—one of the biggest global health threats today.

High-Energy Drug Manufacturing: The Cost of Precision

Producing pharmaceutical ingredients requires high temperatures, specialized equipment, and energy-intensive processes.

1. API production alone contributes to nearly 25% of pharma’s total emissions. [2]

2. The industry relies on petrochemical-based solvents, many of which are hazardous to both the environment and factory workers.

Supply Chain Waste: Overproduction & Inefficiency

Pharmaceutical supply chains are complex and global, leading to significant emissions and material waste.

1. Overproduction of drugs leads to expired medications being discarded, resulting in millions of tons of pharmaceutical waste each year.

2. Cold-chain logistics—which require constant temperature control for vaccines, insulin, and biologics—consume massive amounts of energy.

3. Packaging waste—from single-use plastics to multilayer blister packs—adds to the growing waste crisis.

Regulatory Backlash Is Coming: The Pressure to Clean Up

With growing awareness of the industry’s environmental impact, regulators are stepping in to enforce stricter sustainability policies.

1. The EU’s Green Deal & Carbon Border Tax will place higher scrutiny on pharma’s supply chain emissions, forcing companies to prove sustainability at every stage of production.

2. The U.S. SEC’s climate disclosure rules will make it mandatory for pharmaceutical companies to report their carbon emissions, increasing transparency and accountability.

3. China’s tougher environmental policies will impact global supply chains, pushing pharma companies to adopt cleaner production methods to maintain access to key markets.

For companies that aren’t prepared, this means more audits, higher operational costs, and the risk of non-compliance penalties.

But there’s another challenge. Most companies aren’t tracking their environmental impact in real time.

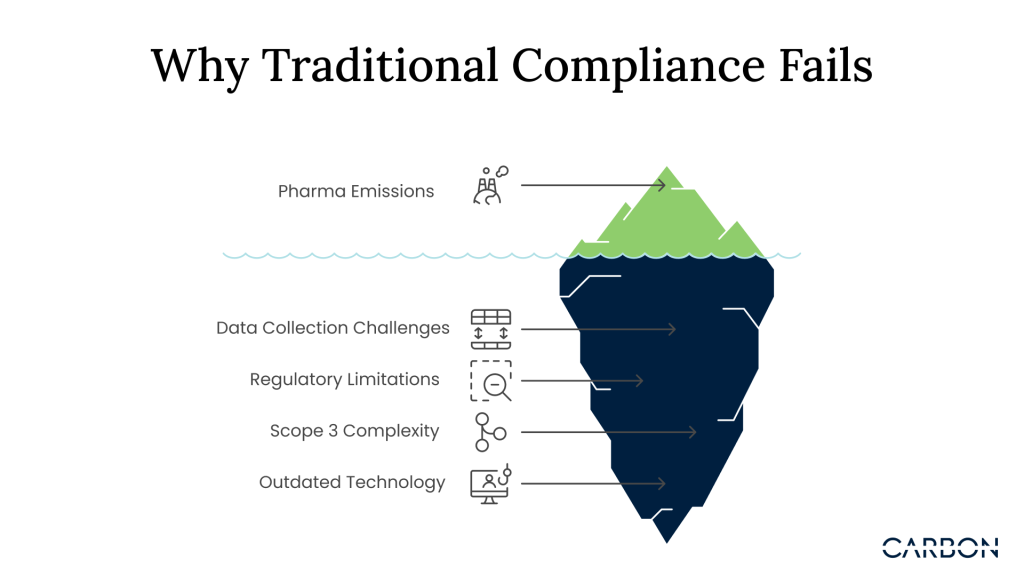

Why Traditional Compliance Fails

The biggest issue? Most pharma companies still rely on outdated, manual methods for emissions tracking and waste management.

1. Data collection is slow and inconsistent, relying on spreadsheets, periodic audits, and self-reported supplier estimates.

2. Regulatory audits only capture a snapshot in time, meaning pollution spikes can go undetected for months.

3. Companies struggle with Scope 3 emissions tracking, making it difficult to accurately measure supply chain emissions.

Without real-time monitoring, predictive insights, and automated compliance tracking, companies are always reacting to sustainability challenges instead of proactively preventing them.

That’s where AI comes in.

With AI-powered monitoring, predictive analytics, and smart compliance tools, pharmaceutical development can turn sustainability from a challenge into an opportunity.

Up next: How AI is transforming the pharmaceutical industry’s approach to waste and emissions management.

How Artificial Intelligence in the Pharmaceutical Industry is Reducing Toxic Waste & Emissions

If there’s one thing we know about the pharmaceutical manufacturing process, it’s that precision is everything. Every drug, every batch, every ingredient has to be carefully measured and controlled.

But when it comes to waste, emissions, and energy use, things aren’t always so exact. Despite the industry’s best efforts, hazardous wastewater, excessive chemical waste, and sky-high energy consumption remain big challenges.

That’s where AI is stepping in to change the game, helping pharma go from reactive cleanup to proactive prevention.

Let’s look at how AI is making sustainability smarter, faster, and more effective.

Real-Time Wastewater & Emissions Monitoring

Pharma plants deal with a lot of wastewater. We’re talking solvents, active pharmaceutical ingredients (APIs), and other chemical byproducts that, if not managed properly, can end up in rivers, lakes, and even drinking water.

The problem? Most facilities test wastewater periodically, which means pollution can go unnoticed for weeks or months.

1. AI-powered sensors monitor wastewater 24/7, detecting pollutants in real time.

2. Machine learning algorithms flag unusual spikes before they become a regulatory nightmare.

3. AI-driven treatment systems optimize chemical dosing, ensuring wastewater is treated efficiently without excess resource use.

Real-World Example: AI in Wastewater Treatment

Researchers have been using AI to optimize pharmaceutical wastewater treatment, making it more efficient, cost-effective, and reliable. AI-driven systems can:

1. Monitor contaminants in real time instead of waiting for lab tests.

2. Predict and optimize treatment processes, reducing waste and costs.

3. Detect water quality issues early, preventing environmental violations.

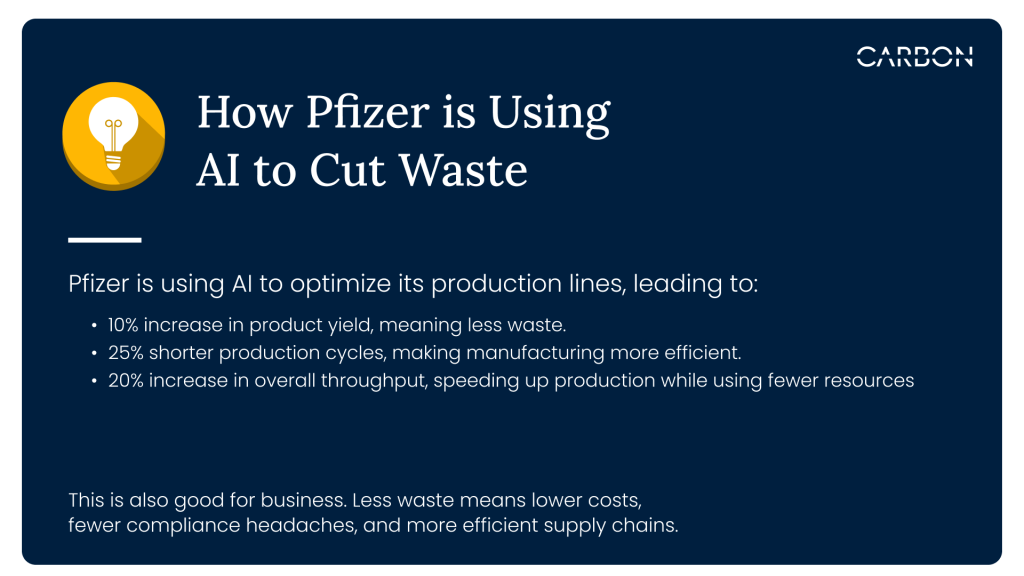

Predictive Analytics for Waste Reduction

A huge part of pharma industry waste comes from overproduction, excess chemical use, and inefficient processes. AI is fixing that by making manufacturing smarter.

1. AI forecasts exactly how much of each ingredient is needed, preventing waste before it happens.

2. Self-learning models adjust production processes, minimizing hazardous byproducts.

3. AI analyzes market demand to prevent overproduction, reducing expired drug waste.

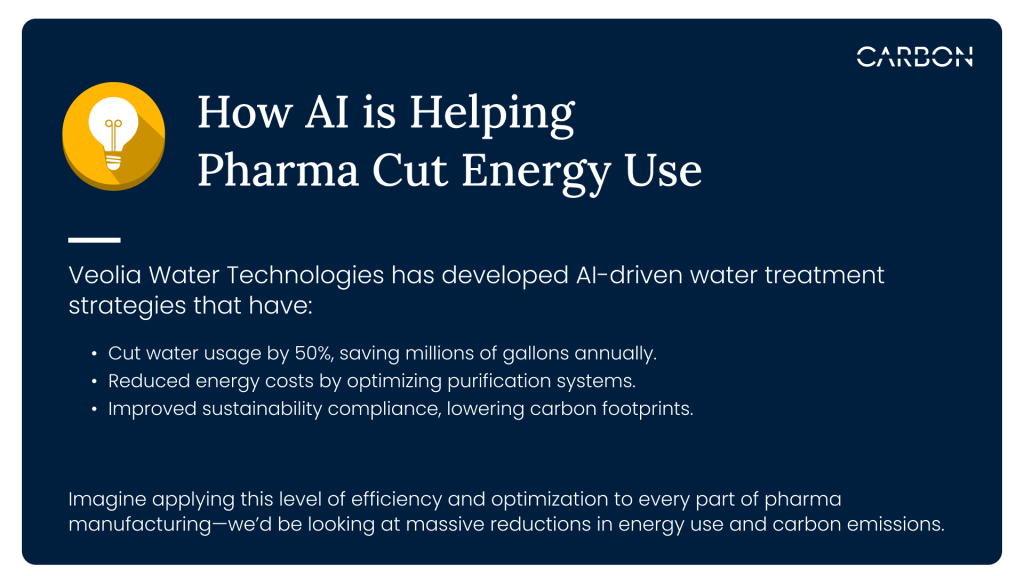

Smart Energy Optimization in Drug Manufacturing

Pharma plants consume a ridiculous amount of energy. Between 24/7 cleanroom operations, cold storage, and complex chemical processing, it adds up fast.

AI is helping slash energy consumption without disrupting production.

1. AI predicts peak energy demand and shifts operations to off-peak hours.

2. It optimizes heating, cooling, and ventilation to reduce excess power use.

3. AI integrates renewable energy sources, helping companies rely less on fossil fuels.

Up next: How AI is helping pharma stay ahead of environmental regulations while ensuring full transparency and accountability.

AI & Regulatory Compliance: The Future of Environmental Accountability

For years, compliance in the pharmaceutical industry has been treated as a process of filing reports, passing audits, and meeting minimum legal requirements. But the game is changing.

Regulators, investors, and even consumers are no longer satisfied with periodic reports and estimated emissions data. They want real-time transparency, accurate carbon tracking, and full supply chain accountability.

Pharma companies that continue reacting to regulations rather than proactively managing sustainability risks will face hefty fines, reputational damage, and operational setbacks.

That’s why AI is now an essential compliance tool for turning sustainability into a competitive advantage.

Why Compliance is No Longer Just About Avoiding Penalties

Historically, compliance was about staying out of trouble, making sure emissions didn’t exceed limits, waste disposal followed guidelines, and audits were clean. But today, compliance is about much more than avoiding penalties.

1. Regulators are tightening the screws: New policies require companies to prove they are actively reducing emissions, not just reporting them.

2. Scope 3 emissions are now under scrutiny: Pharma companies must track and disclose emissions from their entire supply chain, including suppliers, transportation, and product disposal.

3. ESG performance is a business metric: Investors and partners are ranking companies based on sustainability performance, not just profitability.

The takeaway? Compliance is now a business issue. Companies that lag behind in sustainability reporting will lose contracts, investors, and consumer trust.

Why Pharma Companies Struggle With Compliance

Even the most well-intentioned sustainability teams face major challenges in tracking emissions and waste across complex global supply chains.

1. Data silos and inconsistent reporting: Many pharma companies collect environmental data manually—leading to incomplete, outdated, or inaccurate reports.

2. Regulatory audits are static: Traditional audits happen once or twice a year, meaning pollution or waste spikes go unnoticed for months.

3. Hidden supplier emissions: Many companies lack visibility into the carbon footprint of their suppliers, making it easy to underestimate their true environmental impact.

Without real-time tracking and predictive insights, companies can’t act fast enough to prevent compliance failures, leading to last-minute regulatory scrambles and financial risk.

This is where AI is a game-changer.

AI as a Compliance Game-Changer

Apart from tracking, AI can predict, prevent, and optimize compliance related tasks.

Automated Scope 1, 2, and 3 emissions tracking: AI maps every part of the supply chain in the pharmaceutical industry, from raw material extraction to final product distribution, giving companies full visibility into emissions data.

Predictive risk analysis: AI can flag potential compliance violations before they happen, allowing companies to adjust production processes, supply chain choices, or waste disposal methods proactively.

Real-time AI-powered audits: AI eliminates human error in compliance reporting, ensuring consistent, verifiable environmental records without the manual workload.

AI + Blockchain integration for tamper-proof records: AI-driven compliance platforms use blockchain to create immutable records, preventing greenwashing or manipulated emissions data.

Example: Pharma companies can automatically verify supplier emissions data, ensuring sustainability claims are backed by actual, traceable metrics.

The result? Companies using AI stay ahead of audits, reducing legal risk, lowering compliance costs, and proving their ESG leadership to investors and regulators.

The Rise of ESG in The Pharmaceutical Industry: Why AI-Driven Compliance Matters

Investors are prioritizing ESG-driven pharma companies

- Investment funds and institutional investors are putting their money into companies with transparent sustainability records.

- Companies that fail to provide verifiable emissions data may lose funding opportunities.

Consumers demand greener pharma brands

- Public awareness of pharmaceutical pollution and carbon footprints is growing.

- Companies with clear, AI-driven sustainability strategies will have a competitive edge.

AI builds credibility, trust, and long-term resilience

- Sustainability helps businesses stay relevant, competitive, and future-proof.

- AI-powered compliance systems help pharma companies shift from defensive sustainability (reacting to regulations) to offensive sustainability (leading the market in green innovation).

AI is Turning Pharma Compliance Into a Strategic Advantage

Companies that view compliance as a regulatory burden will struggle to keep up.

But companies that use AI to turn compliance into a proactive, automated, and data-driven strategy will:

1. Lower legal and financial risks by avoiding last-minute compliance scrambles.

2. Reduce operational costs by streamlining sustainability tracking and reporting.

3. Win investor confidence by proving real-time ESG transparency.

4. Attract eco-conscious consumers looking for sustainable pharma brands.

The next step? Moving beyond compliance and into full-scale sustainability transformation.

Next up: How AI is driving the pharmaceutical industry’s transition to a Net-Zero future.

The Road Ahead: AI’s Role in Pharma’s Net-Zero Transition

Regulatory compliance isn’t enough anymore.

Governments, investors, and consumers want more than legal minimums—they want real commitments to carbon neutrality, waste reduction, and sustainable operations. In short, pharma needs to go beyond compliance and prove it’s on a net-zero path.

That’s where AI is stepping in. From drug repurposing to smart waste disposal to ethical supply chains, AI is making sustainability in pharma smarter, more efficient, and actually achievable.

The Shift from Pharma Compliance to Carbon-Neutral Drug Manufacturing

AI is helping design drugs with lower carbon footprints from the start

- Traditional drug production relies on petrochemical-based solvents and energy-intensive synthesis pathways, creating large amounts of hazardous waste.

- AI is accelerating the discovery of “green chemistry” alternatives, helping scientists develop low-carbon formulations that don’t depend on fossil-derived ingredients.

Example: AI-driven predictive modeling is being used to identify solvent-free synthesis methods for Active Pharmaceutical Ingredients (APIs), reducing hazardous waste by up to 40% in some production processes.

Cold-chain logistics optimization—AI is cutting emissions where pharma needs it most

- Vaccines, biologics, and temperature-sensitive drugs require 24/7 cold storage and precise transportation controls—one of the most energy-intensive parts of the supply chain in the pharmaceutical industry.

- AI-powered logistics platforms optimize routes, predict cooling needs, and prevent energy waste in cryogenic storage, reducing carbon-intensive overcooling.

Example: AI-driven cryogenic monitoring systems are now being used in mRNA vaccine storage, helping reduce excessive refrigeration energy while maintaining drug stability.

AI-powered drug repurposing—waste reduction at the molecular level

- Every year, billions of dollars worth of medications expire before they’re used, leading to unnecessary waste and emissions.

- AI is helping scientists identify new therapeutic applications for surplus drugs, preventing waste and extending the lifecycle of existing medications.

Example: AI-based repurposing models helped discover that certain expired antiviral drugs could be reformulated for new treatments, reducing unnecessary pharmaceutical waste in early-stage studies.

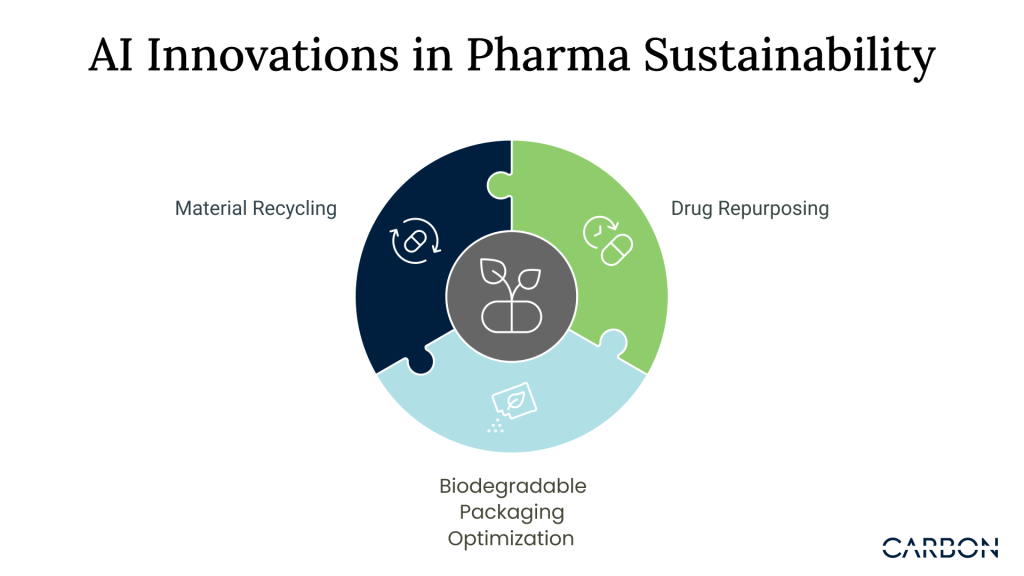

AI-Powered Circular Economy in Pharma

Pharma waste is a massive problem. Expired drugs, unused raw materials, overproduction—it all adds up to billions of dollars lost and tons of unnecessary waste.

AI is changing that by making waste reduction a built-in part of the system, not an afterthought.

Machine Learning for Drug Repurposing

- AI can analyze expired or surplus drugs and identify alternative uses, preventing them from going to waste.

- Example: Instead of discarding medications after their patent period, AI can help researchers find new formulations or applications, extending their lifecycle.

AI-Driven Biodegradable Packaging Optimization

- AI is helping pharma companies redesign packaging to be biodegradable, compostable, or easily recyclable.

- Example: AI-assisted material science is identifying bio-based alternatives to traditional plastic pill bottles and blister packs.

AI-Assisted Material Recycling

- AI models sort and process pharma waste into usable raw materials for new drug production, reducing dependence on virgin materials.

- Example: Solvent recovery systems, optimized by AI, help recapture chemicals from drug manufacturing for reuse, reducing toxic waste.

By using AI in drug repurposing, packaging innovation, and material recycling, pharma can reduce landfill waste and cut emissions before they even happen.

Decentralized AI for Smarter Waste Disposal

Not all waste can be reused or recycled, but that doesn’t mean it has to be wasted. AI is helping turn pharmaceutical waste into energy, making disposal smarter and more sustainable.

AI-Powered Waste-to-Energy Conversion

- Instead of landfilling non-recyclable pharma waste, AI helps identify the best ways to convert it into alternative fuels.

- Example: AI-driven gasification processes break down organic waste from drug production, turning it into biofuels or synthetic gas.

AI-Powered Waste-to-Hydrogen Tech

- Some pharma byproducts can be used to produce hydrogen, an emerging clean energy source.

- AI optimizes waste-to-hydrogen systems, ensuring that as much usable fuel as possible is extracted.

Predictive Analytics for Real-Time Waste Tracking

- AI ensures every waste product is properly categorized and repurposed, reducing landfill dependency.

- Example: AI can help pharma companies map out their waste streams and redirect materials to secondary industries for reuse.

This is waste disposal done right—using data, automation, and advanced energy conversion to turn what was once useless into something valuable.

AI & Smart Supply Chains: The Key to Carbon-Neutral Pharma

A huge part of pharma’s carbon footprint doesn’t come from manufacturing, it comes from moving products across the globe.

Logistics, storage, cold-chain transportation, every step adds emissions. AI is helping cut those emissions at the source.

Predictive Analytics for Carbon-Efficient Logistics

- AI ensures shipments are grouped, routed, and scheduled in the most energy-efficient way possible, reducing unnecessary fuel consumption.

- Example: AI logistics platforms are helping pharma reduce transport-related emissions.

AI Models Optimizing Cold Chain Transportation

- AI continuously monitors and adjusts storage conditions to prevent unnecessary energy use while keeping medications stable.

- Example: AI-powered sensors in vaccine storage facilities can reduce cooling energy demand, helping lower costs and carbon impact.

AI-Powered Ethical Sourcing Models

- AI helps pharma companies evaluate and select suppliers that meet sustainability criteria, ensuring raw materials come from vetted, low-carbon sources.

- Example: AI-driven audits are helping companies eliminate high-carbon suppliers from their value chains, cutting emissions at the source.

With AI optimizing logistics, energy use, and supplier selection, pharma companies can reduce emissions across their entire supply chain, moving closer to true carbon neutrality.

In short, pharma’s sustainability challenges are massive, but with AI, they’re solvable.