Key Takeaways

- Carbon taxes on imports are rising fast

- High-emission supply chains are a financial liability

- Scope 3 emissions drive brand, investor, and regulatory risk

- Carbon shoring = competitive advantage, not just compliance

- Visibility is the first step toward control

- Real data > estimates when tackling Scope 3

- Cutting emissions requires systemic supply chain changes

- CSB turns scattered efforts into a repeatable strategy

- Continuous monitoring fuels long-term resilience

You’re about to face a carbon tax bill you never saw coming.

The EU CBAM (Carbon Border Adjustment Mechanism) is just the opening act. Global carbon taxes are spreading fast, targeting industries that rely on high-emission supply chains.

Steel, cement, chemicals—if your suppliers are pumping out carbon, your bottom line is about to take a hit.

But this isn’t about compliance. It’s about profit, competitiveness, and staying relevant in a market where low-carbon supply chains are quickly becoming the gold standard.

Every executive worth their salt is rethinking supply chains right now. Because the ones who adapt first?

They’re the ones who’ll dominate the future.

And it’s not just regulation driving the change. Consumers want low-carbon products. Investors demand ESG performance.

Every weak link in your supply chain is a compliance risk and a reputational bomb waiting to go off.

This article breaks down the forces pushing companies toward carbon shoring and restructuring supply chains to minimize Scope 3 emissions.

We’ll explore why this shift is happening, where it’s heading, and how you can stay ahead of the curve using a general model called the Carbon Shoring Blueprint (CSB).

Because while most companies are scrambling to catch up, the smart ones are already making the switch.

Why Carbon Shoring Is Becoming Impossible to Ignore

You can feel the pressure building. Regulations are tightening, markets are shifting, and investors are demanding supply chains decarbonization.

Ignoring Scope 3 emissions used to be a blind spot. Now, it’s a flashing red light.

The term “carbon shoring” is everywhere because it’s a survival strategy now.

And if you’re still clinging to high-emission supply chains, you’re about to get left behind.

Regulatory Pressure: The Noose Tightens

The EU CBAM (Carbon Border Adjustment Mechanism) is just the start. Introduced to level the playing field between carbon-regulated industries and those operating with fewer restrictions, CBAM places a carbon price on imports based on their embedded emissions.

And right now? It’s only aimed at a handful of industries—steel, cement, aluminum, fertilizers, electricity, and hydrogen.

But the list is expanding. And if your industry isn’t on it yet, it’s only a matter of time.

According to the European Commission, CBAM could be extended to cover more sectors like chemicals, textiles, and machinery by 2030. And it’s not just Europe.

The U.S., Canada, Japan, and India are all moving toward similar carbon tax frameworks.

Here’s the bottom line: If your supply chain stretches across borders, your carbon footprint is no longer just your problem. It’s a cost you’ll have to pay for unless you find a way to cut it down.

Market Demand: The Consumer Shift You Can’t Ignore

Regulation isn’t the only force driving carbon shoring. Consumer expectations are evolving just as fast.

The 2025 Edelman Trust Barometer found that 64% of consumers worldwide are now “belief-driven buyers.” They actively choose brands based on social, environmental, and political commitments.

And when it comes to climate action? They’re not willing to wait.

Investors are on the same page. BlackRock, Vanguard, and other institutional giants are doubling down on ESG performance. They want data, not promises.

And if your supply chain is dragging down your ESG score, you’re already losing ground.

But it’s not about placating consumers or investors. It’s about building resilience.

Because the companies that anticipate these shifts? They’re the ones who stay profitable when everyone else is playing catch-up.

Brand Reputation & Competitive Advantage: What Happens When You Ignore Scope 3

If you think a strong reputation will protect you from backlash, think again. Consumers and stakeholders are growing savvier.

They understand that your emissions aren’t just what happens inside your factories. They’re about everything that touches your supply chain.

Here’s the truth: Companies that aren’t investing in carbon shoring are falling behind and putting their entire business model at risk.

Case Studies: How Companies Are Staying Ahead

Some companies are already making the shift, meeting regulations while setting the standard.

1. ArcelorMittal (Steel)

Faced with mounting regulatory pressure, ArcelorMittal has implemented carbon shoring strategies across its European operations. By integrating renewable energy sources and collaborating with low-carbon suppliers, the company has reduced Scope 3 emissions in targeted processes.

2. Holcim (Cement)

Holcim, a global leader in building materials, has rolled out a carbon shoring initiative to reduce emissions from cement production. By working with suppliers to adopt alternative fuels and optimizing transportation logistics, the company has cut a quarter of its total Scope 3 footprint.

3. BASF (Chemicals)

The chemical giant BASF is applying carbon shoring principles to its procurement and logistics operations. By optimizing supply routes, integrating renewable energy sources, and partnering with low-carbon suppliers, BASF has reduced its Scope 3 emissions over the past five years.

These companies aren’t waiting for regulations to force their hand. They’re acting now because they understand that compliance is just the baseline.

The real goal is profitability and competitive advantage.

Predictive Analysis for Supply Chain Emissions: Where Carbon Shoring Is Headed

The writing is on the wall. As regulations tighten and consumer expectations shift, companies that fail to address Scope 3 emissions will find themselves boxed in.

By 2030, it’s estimated that over 70% of global carbon emissions will be subject to carbon pricing mechanisms. And as these frameworks expand to include more industries and supply chain segments, the cost of ignoring Scope 3 emissions will only rise.

But it’s not just about avoiding penalties. The bigger game is seizing opportunities.

Digital carbon accounting tools, predictive analytics, and AI-driven monitoring systems are making it easier than ever to track, optimize, and reduce your supply chain emissions.

The companies that invest in these technologies now? They’re the ones who’ll lead the market when carbon shoring becomes the standard.

Framework to Build Low-Carbon Industrial Supply Chains

Now you know why carbon shoring is becoming impossible to ignore.

The next step? Building a low-carbon supply chain that survives regulation and also thrives because of it.

And it’s not limited to cutting emissions. It’s about creating a supply chain that’s efficient, resilient, and profitable.

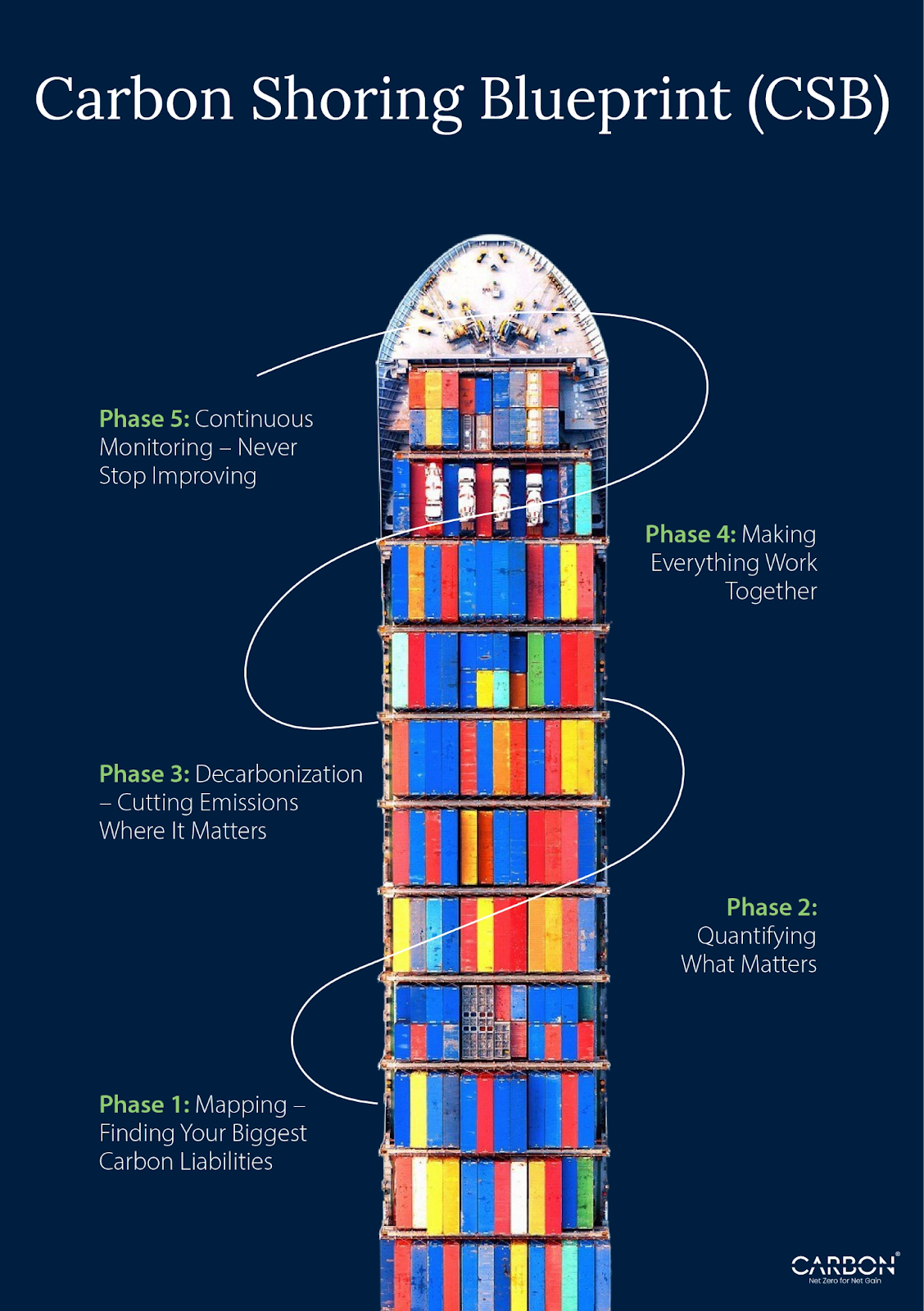

That’s where the Carbon Shoring Blueprint (CSB) comes in. It’s a general framework designed to help companies identify, reduce, and optimize Scope 3 emissions across their supply chains.

Why Existing Models Fall Short

Most carbon reduction strategies fall apart because they’re too narrow. They focus on Scope 1 and Scope 2 emissions, leaving Scope 3 as an afterthought.

And even when companies do try to tackle Scope 3, they treat it like a box-ticking exercise.

The problem?

- Lack of Visibility: If you can’t see your Scope 3 emissions clearly, you can’t control them.

- Fragmented Solutions: Tackling emissions with isolated tools instead of a comprehensive framework leads to inefficiencies.

- Inconsistent Measurement: Without accurate data, you’re just guessing. And guesswork doesn’t cut it when the stakes are this high.

The Carbon Shoring Blueprint (CSB)

This is a way of rethinking your supply chain from the ground up. And it starts with visibility.

Phase 1: Mapping – Finding Your Biggest Carbon Liabilities

Before you can reduce emissions, you need to know where they’re coming from. And for most companies, that’s not as straightforward as it sounds.

Your supply chain is a network. And every node in that network is a potential carbon emitter. Raw material extraction, manufacturing processes, transportation, distribution—it’s all connected.

The first step is mapping. And it’s more than just a rough estimate.

It’s about creating a detailed map of your entire supply chain, pinpointing where emissions are generated and where they can be cut.

Industry Examples:

- Steel: Raw material extraction is one of the largest contributors to Scope 3 emissions. Companies need to map their suppliers’ practices, transportation routes, and manufacturing processes to identify inefficiencies.

- Cement: High-carbon production processes are well-known, but transportation and distribution often go overlooked. Mapping these emissions is critical for building a low-carbon supply chain.

- Chemicals: Distribution processes contribute heavily to Scope 3 emissions. Mapping routes, storage methods, and transportation logistics is the first step toward cutting emissions.

Phase 2: Measurement – Quantifying What Matters

You can’t optimize what you can’t measure. And when it comes to Scope 3, most companies are relying on guesswork.

The Measurement phase of the CSB involves gathering precise data from every part of your supply chain.This helps you make better estimates and build a database that gives you real-time insights.

Tailored Solutions for Various Industries:

- Steel: Using advanced sensors and real-time monitoring tools to track emissions from raw material extraction, processing, and transportation.

- Cement: Implementing carbon accounting software to monitor emissions from kilns, coolers, and transport fleets.

- Chemicals: Leveraging digital tracking tools to optimize distribution networks and reduce logistical inefficiencies.

- Manufacturing: Monitoring energy use across multiple facilities to pinpoint inefficiencies.

- Food & Beverage: Tracking emissions tied to refrigeration, transportation, and raw material sourcing.

This phase is about collecting data, and turning that data into actionable insights.

Phase 3: Decarbonization – Cutting Emissions Where It Matters

Once you have a clear map of your supply chain and precise data to work with, it’s time to start cutting emissions. And that means more than just tweaking processes.

It means rebuilding them.

Three Key Strategies for Decarbonization:

- Renewable Energy Integration:

- Using solar, wind, or hydropower wherever possible to replace carbon-intensive energy sources.

- Example: Steel companies adopting renewable energy to power electric arc furnaces.

- Using solar, wind, or hydropower wherever possible to replace carbon-intensive energy sources.

- Efficient Transportation:

- Optimizing logistics networks to reduce fuel consumption and emissions.

- Example: Chemicals and petrochemicals firms consolidating shipping routes to minimize carbon output.

- Optimizing logistics networks to reduce fuel consumption and emissions.

- Supplier Standards:

- Collaborating with suppliers to improve their own carbon footprints.

- Example: Cement manufacturers partnering with low-carbon raw material suppliers to reduce overall emissions.

- Collaborating with suppliers to improve their own carbon footprints.

Decarbonization is a process. And the companies that excel are the ones who make it a continuous improvement cycle.

Phase 4: Integration – Making Everything Work Together

Here’s where most companies drop the ball. They install new tools, run them for a while, and then go back to business as usual.

But real carbon shoring requires integration. Every tool, every process, every improvement needs to work together seamlessly.

This phase focuses on creating a unified system where monitoring, measurement, and decarbonization efforts feed into each other.

This ensures your entire organization is aligned with your carbon reduction goals.

Phase 5: Continuous Monitoring – Never Stop Improving

Even the best systems need maintenance. And when it comes to carbon shoring, continuous monitoring is essential.

Using predictive analytics helps identify inefficiencies before they cause problems, ensuring you can fix issues and decarbonize supply chains that improves itself over time.

Behavioral Science Integration

Why do companies resist carbon shoring? It’s not always about cost. Sometimes, it’s psychological.

- Endowment Effect: Companies overvalue their existing supply chains, making them reluctant to change.

- Bystander Effect: When no one else is innovating, it feels safer to stick with the status quo.

- Primacy Effect: The first models companies implement often become the default, even when better options are available.

Understanding these biases is essential for making real progress. The companies that succeed are the ones willing to challenge their own assumptions.

Make the Shift Before the Shift Moves You

You’ve seen where the pressure is coming from.

Regulations tightening. Consumers demanding change. Investors demanding data.

Carbon shoring goes beyond mere compliance by helping you stay relevant. And if you’re still waiting for the perfect moment to overhaul your supply chain, you’re already behind.

The companies that win are the ones who see carbon shoring as an opportunity, not just a compliance hurdle. They’re building supply chains that are resilient, efficient, and profitable.

And here’s the truth: You don’t have to start from scratch.

You already have the pieces. You just need to rearrange them.

The Carbon Shoring Blueprint (CSB) isn’t a silver bullet either. It’s a framework, a way to map your emissions, measure what matters, cut what you can, integrate your systems, and keep improving.

The ones who figure this out now will own the future. The rest? They’ll be left catching up.

Know more at https://carbonminus.com/contact-us/

FAQs

Q: How is carbon shoring different from nearshoring or reshoring?

Carbon shoring isn’t about geography—it’s about carbon. It’s the practice of restructuring supply chains to reduce embedded emissions, regardless of location.

Q: Where do most Scope 3 emissions come from in a supply chain?

It varies by industry, but top contributors often include raw material extraction, manufacturing processes of suppliers, and transportation.

Q: Is it possible to reduce Scope 3 without changing suppliers?

Yes—start with better visibility, energy-efficient logistics, and collaborative decarbonization plans. But long-term impact often requires rethinking supplier standards.

Q: What kind of tech is needed to implement CSB?

Carbon accounting platforms, AI-driven monitoring tools, and integration systems that connect supply chain, procurement, and ESG reporting.

Q: What’s the business case for carbon shoring?

It reduces tax exposure, improves ESG ratings, satisfies investor and customer demands, and strengthens your brand against future disruption.