Key Takeaways

- Climate volatility is the new normal

- Static resilience strategies are obsolete

- Hydroclimate extremes disrupt water, energy, and infrastructure

- Operational downtime = emissions, waste, and lost revenue

- Resilience must be predictive, adaptive, and real-time

- DROM turns chaos into continuous improvement

- Real-time data + AI = smarter, faster adaptation

- Early adopters will lead on compliance and continuity

- Fortresses fail—flexible systems survive

Forget about gradual warming. The real threat is extreme volatility.

Climate change isn’t moving in a straight line. It’s lunging from one extreme to another—droughts that parch resources dry, followed by floods that wipe away infrastructure.

This cycle of hydroclimate whiplash is the new normal. And for industrial giants that rely on stable conditions, it’s a nightmare.

Cooling systems that dry up when water supplies run low. Processing facilities that shut down when floods knock out transportation networks. Infrastructure weakened by constant temperature swings.

The worst part? Most companies aren’t ready.

They’re still treating resilience like it’s about building walls and bolting down equipment.

But real resilience isn’t about fortification. It’s about dynamic, adaptive energy and resource management—the kind that shifts and responds in real-time.

This article introduces a structured approach called the Dynamic Resilience Optimization Model (DROM)—a framework that combines predictive analytics, real-time monitoring, and adaptive management to keep operations running smoothly no matter what the climate throws at them.

Because in a world where weather systems have gone haywire, the only companies that survive are the ones that adapt faster than the chaos around them.

Why Your Resilience Strategy Isn’t Ready For What’s Coming

The playbook you’ve been using for resilience? It’s outdated.

Infrastructure fortification, redundancy systems, disaster recovery plans—these are the tactics companies have relied on for decades.

But in a world where hydroclimate whiplash is becoming the norm, those static approaches aren’t enough.

Because here’s the truth: You can’t outbuild chaos.

Droughts one year. Floods the next. Temperatures swinging from record highs to record lows within months.

Climate change isn’t following a predictable path, and neither can your resilience strategy.

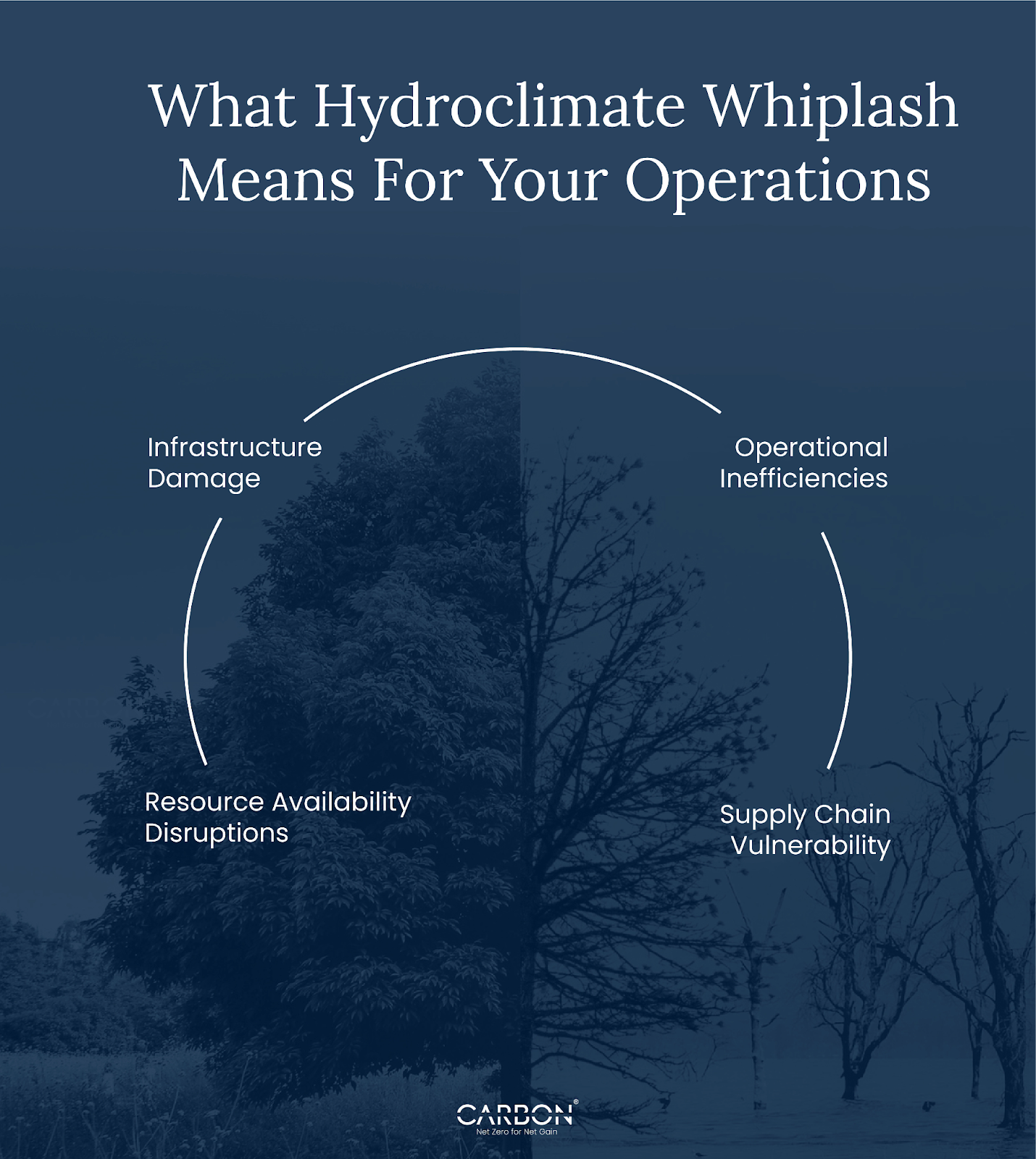

What Hydroclimate Whiplash Means For Your Operations

Hydroclimate whiplash isn’t a theoretical threat anymore. It’s already causing massive disruptions across industries.

And the worst part? Most companies don’t even see it coming until it’s too late.

Resource Availability Disruptions

Droughts are wiping out water supplies in regions that once relied on consistent rainfall. For industrial giants that need water for cooling systems, processing, and material handling, this is a critical vulnerability.

Example: A cement plant relying on water-cooled kilns could see operational efficiency drop during severe drought conditions, leading to higher energy consumption and emissions.

The irony? The more inefficient the system becomes, the more it contributes to the very climate instability that’s causing the problem.

Infrastructure Damage

Flooding, subsidence, and erosion are wreaking havoc on facilities built for predictability. When extreme weather strikes, physical infrastructure takes the hit.

- Flooding: Submerges equipment, weakens foundations, and disrupts transportation networks.

- Erosion: Slowly eats away at structural integrity, leading to costly repairs or outright failures.

- Subsidence: Shifting ground destabilizes heavy machinery and damages buildings.

Example: A steel manufacturing facility located near a river could face extended downtime during flood events, losing millions in revenue while simultaneously pumping out excess carbon from backup systems.

Operational Inefficiencies

Temperature fluctuations are a silent killer of efficiency. They might not cause immediate shutdowns, but they erode productivity bit by bit.

- Chemical Processes: Variability in temperature can disrupt chemical reactions, leading to inconsistent product quality and increased waste.

- Food Processing: Rapid shifts from heat to cold can compromise refrigeration systems, spoiling products and increasing energy consumption.

- Manufacturing: Thermal stress on equipment can accelerate wear and tear, shortening lifespans and driving up maintenance costs.

Example: A food and beverage company operating in a climate-vulnerable region could see refrigeration energy costs spike during heatwaves, leading to increased emissions and operational costs.

Supply Chain Vulnerability

It’s not just your own operations at risk. Your suppliers are just as vulnerable to hydroclimate whiplash. And if they go down? You do, too.

Extreme weather disrupts transportation networks, delays shipments, and damages critical infrastructure. And when your suppliers are spread across regions with different climate risks, the problem multiplies.

Example: A chemical company relying on raw materials shipped through ports could face severe delays if those ports are temporarily closed due to flooding or hurricane damage. Even a delay of a few days could result in production slowdowns and lost revenue.

Why Current Resilience Strategies Fail

If you’re relying on physical infrastructure alone to handle these disruptions, you’re missing the point. Because the threats you’re facing are dynamic, not static.

Here’s why current strategies aren’t cutting it:

Reactive Approaches

Most resilience plans are built around the assumption that disruptions are occasional, predictable, and easily manageable. But when extreme weather events are becoming more frequent, more severe, and less predictable, a reactive approach is a recipe for failure.

By the time you respond to a problem, the damage is already done.

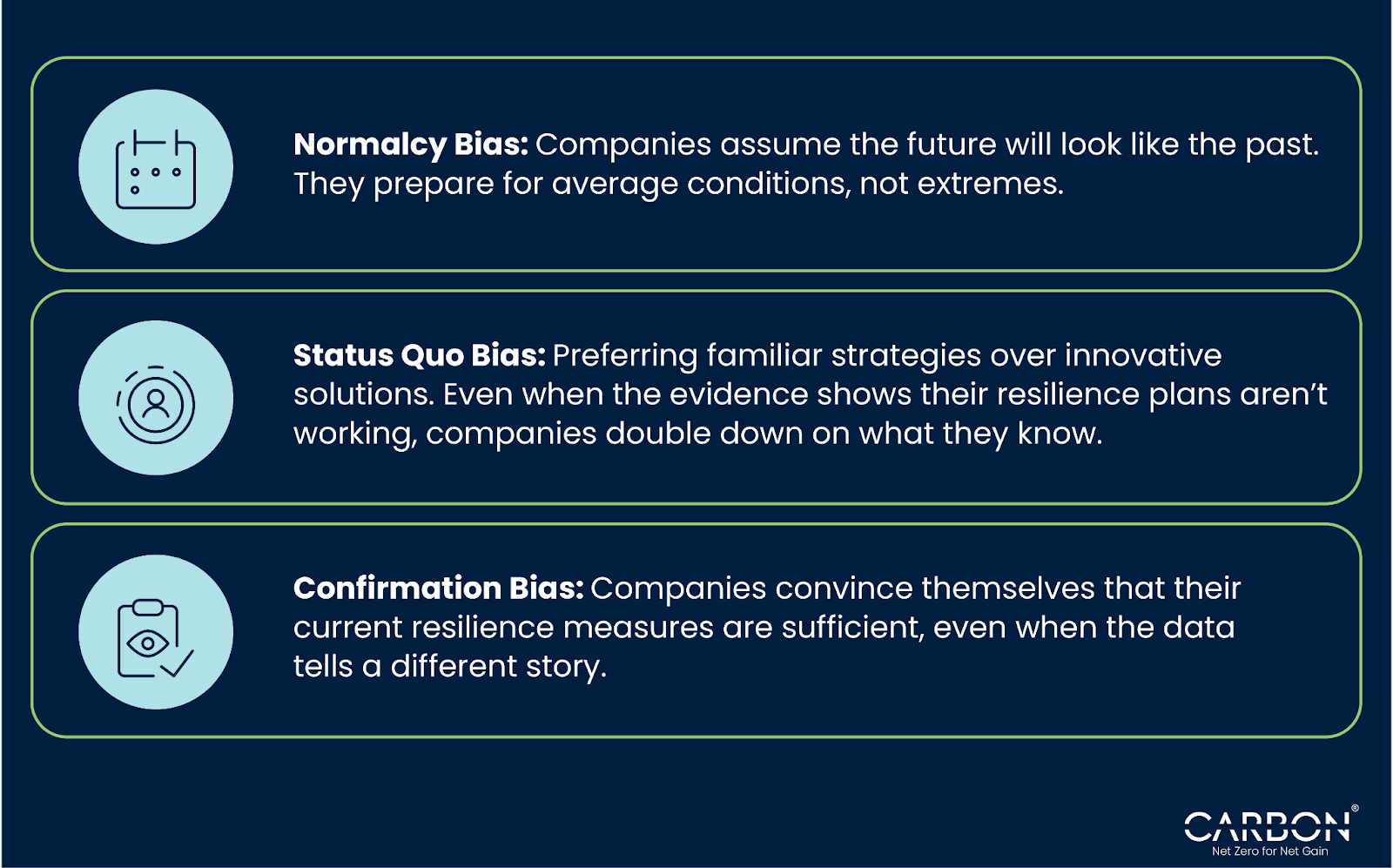

Biases Preventing Change

It’s not just about technology. It’s about the way companies think. And most companies are clinging to outdated frameworks because of deep-seated biases.

These biases are more than psychological quirks. They’re obstacles standing between you and the adaptability you need.

The Contrarian Viewpoint: Why Relying On Infrastructure Fortification Is A Strategic Mistake

Here’s the problem with treating resilience like a fortress: It’s built on the assumption that stability is the norm.

But when the climate itself has become unstable, building walls higher and thicker doesn’t work. It just drives up costs and reduces flexibility.

You might think resilience is about bracing for impact. But it’s actually about adapting to constant change. And the companies that rely solely on infrastructure fortification are setting themselves up for failure.

What’s the alternative? Building resilience into your operational processes, not just your physical structures.

Instead of trying to keep the storm out, you make sure your systems can function no matter what conditions they face.

And that’s where the Dynamic Resilience Optimization Model (DROM) comes in.

Why Real Resilience Is About Adaptation, Not Fortification

If your resilience strategy is built around making your systems stronger, more fortified, and harder to break, you’re already losing.

The companies that succeed in a world of hydroclimate whiplash aren’t the ones with the most robust infrastructure. They’re the ones with the most adaptive systems.

Because here’s the truth: You can’t outbuild climate volatility. But you can outmaneuver it.

And that’s what the Dynamic Resilience Optimization Model (DROM) is all about.

What Is DROM?

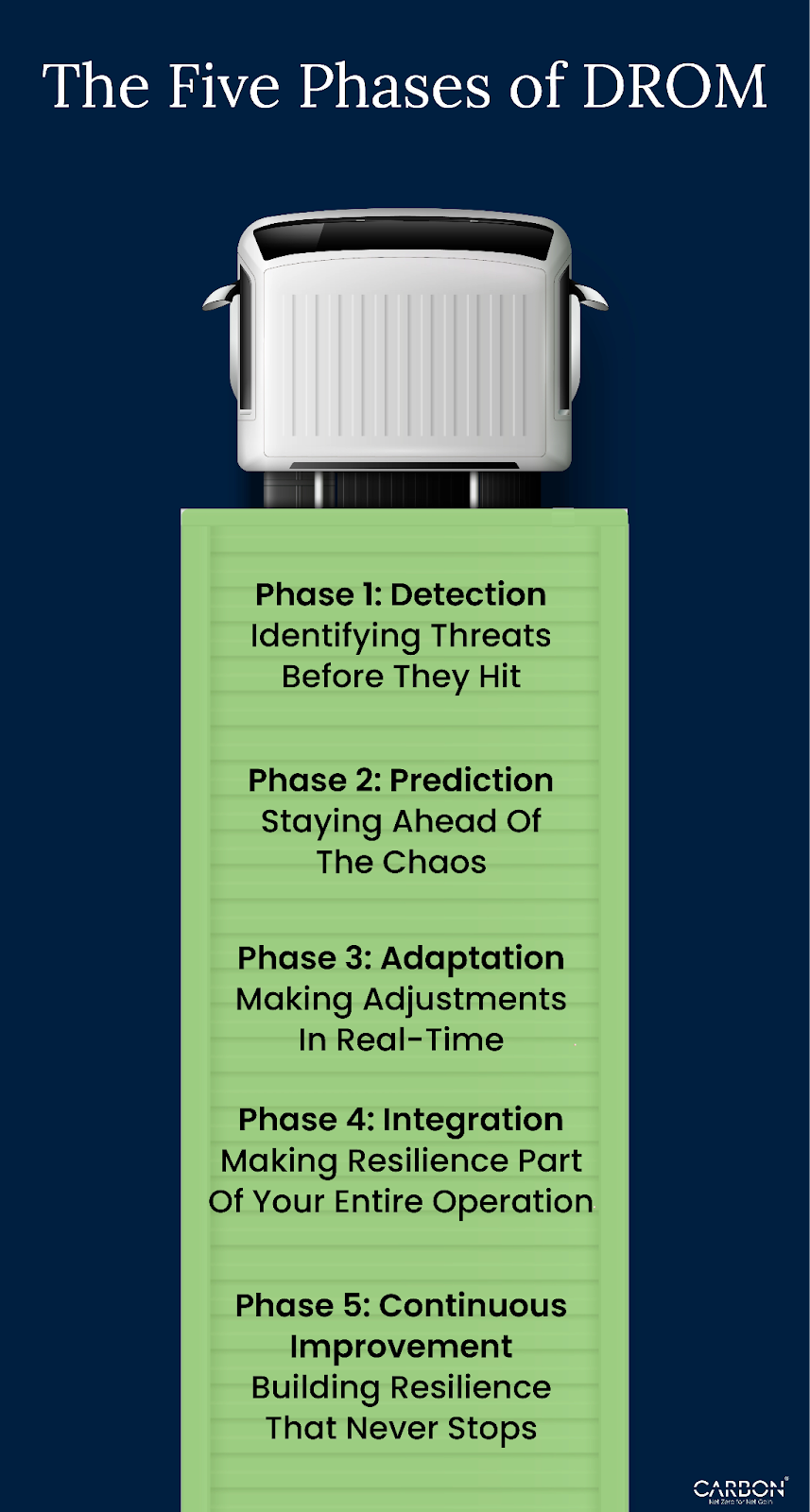

The Five Phases of DROM: How to Build Resilient Supply Chains in Extreme Weather

The DROM framework breaks down resilience into five distinct phases: Detection, Prediction, Adaptation, Integration, and Continuous Improvement.

By following these phases, companies can build resilience that’s proactive, adaptive, and constantly evolving.

Phase 1: Detection – Identifying Threats Before They Hit

You can’t adapt to a threat you don’t see coming.

The first phase of the DROM framework is Detection, using real-time monitoring systems to gather data on environmental conditions, operational performance, and resource availability.

This isn’t just about installing sensors and hoping for the best. It’s about building a system that tracks changes as they happen and recognizes patterns before they turn into crises.

Example: A chemical manufacturing facility using real-time monitoring could detect falling water levels in its cooling systems during an extended drought. By identifying the issue early, the facility might avoid costly shutdowns and prevent damage to sensitive equipment.

Phase 2: Prediction – Staying Ahead Of The Chaos

Once you have real-time data, the next step is turning it into foresight.

The Prediction phase uses AI-driven analytics to forecast disruptions before they occur. This involves identifying patterns, analyzing historical data, and generating predictive models that help companies anticipate what’s coming next.

And it doesn’t stop at predicting weather events. It’s about predicting how those events will impact your operations.

Example: A steel manufacturer could use predictive analytics to forecast the impact of upcoming heatwaves on its cooling systems. By adjusting operational processes in advance, it could reduce energy consumption and prevent equipment damage.

Phase 3: Adaptation – Making Adjustments In Real-Time

Here’s where most resilience strategies fall short. They’re built around static responses to dynamic threats.

But DROM is designed to adapt.

The Adaptation phase involves implementing strategies to optimize resource use and operational processes in real-time. This could mean adjusting cooling rates, modifying supply routes, or even temporarily scaling back operations to prevent catastrophic failures.

Reacting to disasters is one half of that coin. The other half is about making continuous, data-driven adjustments that keep your systems running efficiently even under stress.

Example: A food and beverage company operating in a drought-prone region could use DROM to adjust its water usage dynamically, prioritizing critical systems while temporarily scaling back non-essential processes.

The result? Reduced operational stress, lower energy consumption, and a smaller carbon footprint.

Phase 4: Integration – Making Resilience Part Of Your Entire Operation

The most common mistake companies make? Treating resilience like an isolated problem.

They build flood walls, reinforce buildings, and call it a day. But real resilience requires integration, tying predictive maintenance, resource management, and operational monitoring into a cohesive system.

The Integration phase of DROM ensures that your resilience efforts are connected to your broader sustainability goals and operational processes.

Example: A cement manufacturer could integrate predictive analytics into its entire production process, from material sourcing to transportation. By linking predictive resilience tools to its carbon accounting systems, the company might be able to track emissions reductions in real-time, making continuous improvements where needed.

Phase 5: Continuous Improvement – Building Resilience That Never Stops Improving

Resilience isn’t a one-time fix. It’s a continuous process.

The final phase of DROM is about creating a feedback loop where predictive analytics and real-time monitoring constantly refine your systems.

Every time you make an adjustment, you learn something. And every time you learn something, your systems get better.

Example: A petrochemicals firm using DROM could continuously improve its resilience systems by analyzing performance data after each extreme weather event. This ongoing optimization could lead to a reduction in operational downtime and a cut in emissions over five years.

Why Early Adopters Will Be The Last Ones Standing

Here’s the brutal truth: Most companies won’t adapt until it’s too late.

They’ll keep throwing money at infrastructure fortification. They’ll keep clinging to outdated strategies that can’t handle the unpredictable.

And when the next wave of hydroclimate whiplash hits, they’ll be left scrambling to clean up the mess.

But the companies that see the change coming and act now? They’re the ones who’ll dominate the future.

Predictive Analysis: Where Hydroclimate Whiplash Is Headed

If you think extreme weather events are bad now, just wait.

Climate models from the Intergovernmental Panel on Climate Change (IPCC) indicate that the frequency and intensity of extreme weather events will continue to rise over the next decade.

But it’s not just about more heatwaves, floods, and droughts. It’s about the way those events interact—hydroclimate whiplash, where extremes of wet and dry conditions occur in rapid succession.

According to a 2024 study by the World Meteorological Organization (WMO), areas that used to experience droughts and floods as separate, isolated events are now experiencing them within the same season.

The result?

- Water supply disruptions.

- Infrastructure stress and damage.

- Operational inefficiencies.

And the trend is accelerating. As global temperatures rise, the atmosphere holds more moisture, which means more intense rainfall events.

But it also means faster evaporation rates, leading to droughts that hit harder and last longer.

What does that mean for your operation? It means that waiting to adapt is a guaranteed way to get left behind.

The Regulatory Landscape: Compliance Is Just The Beginning

It’s not just the weather that’s changing. It’s the rules.

The Task Force on Climate-related Financial Disclosures (TCFD) and the Corporate Sustainability Reporting Directive (CSRD) are already pushing companies to disclose climate-related risks. But right now, most of that focus is on carbon emissions.

What’s next? Resilience metrics.

As hydroclimate whiplash continues to create operational disruptions, regulators are preparing to expand their frameworks to include resilience reporting. It’s not enough to measure your carbon footprint. You’ll need to prove that your operations can survive the extremes climate change is throwing at you.

According to the 2025 ESG Readiness Report, 80% of companies are unprepared for resilience-related reporting requirements. And the ones that adapt early will have a massive head start.

The writing’s on the wall. If you’re not integrating resilience into your broader sustainability strategy, you’re setting yourself up for compliance failures.

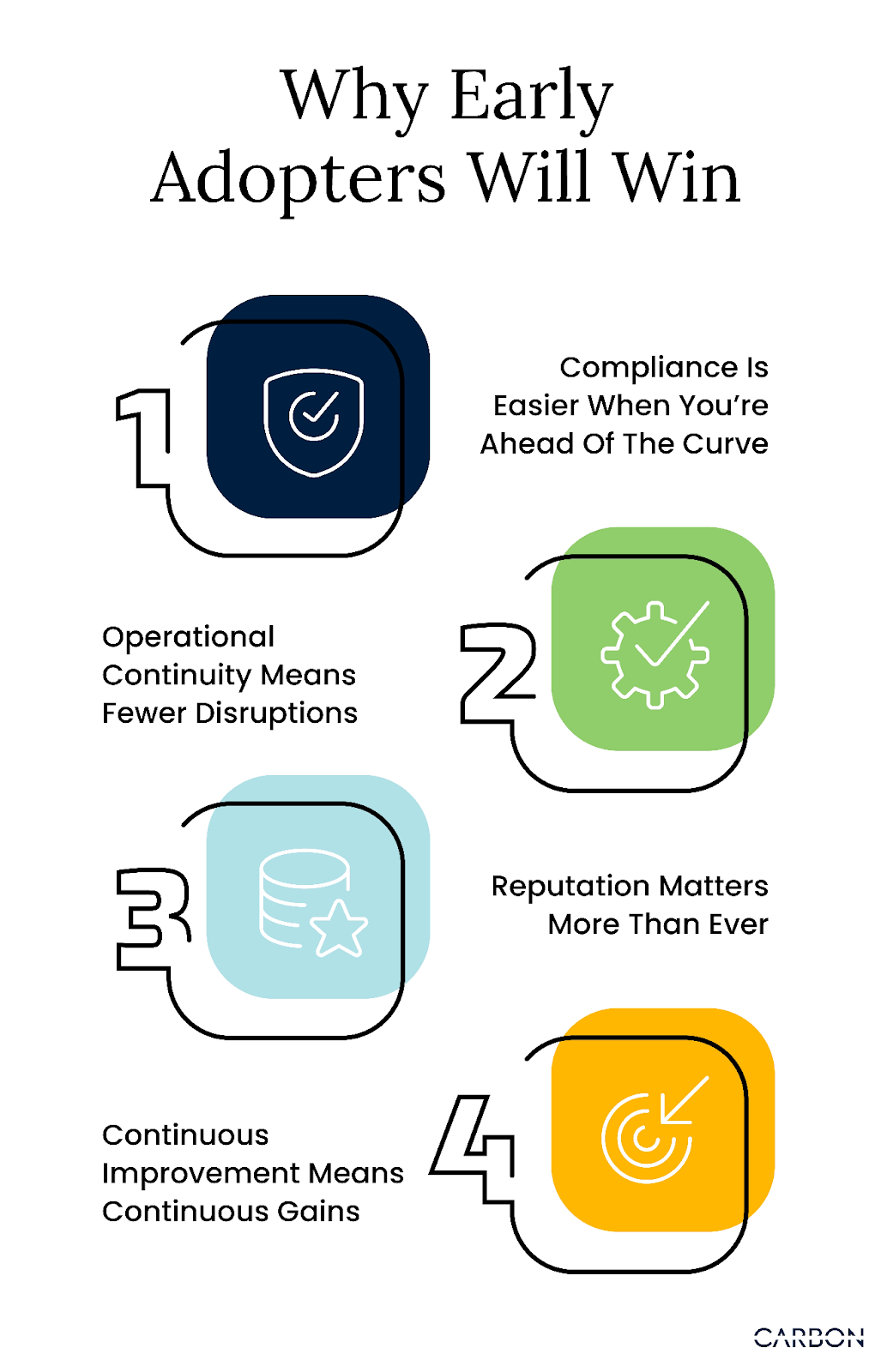

Why Early Adopters Will Win

The companies that embrace DROM now aren’t just preparing for the future. They’re creating a competitive advantage.

Here’s why:

1. Compliance Is Easier When You’re Ahead Of The Curve

If you’re waiting for regulators to force your hand, you’re already behind. Companies that adopt DROM now will be ready to meet future resilience metrics before they’re even required.

And when new reporting frameworks do become mandatory? You’ll be ready. Everyone else will be playing catch-up.

Example: A manufacturing firm that integrates DROM into its operational processes now could meet upcoming resilience metrics with minimal adjustments, while competitors scramble to retrofit outdated systems.

2. Operational Continuity Means Fewer Disruptions

Every time extreme weather disrupts your operations, you lose money. But the companies that use DROM to anticipate and adapt to those disruptions will keep running when everyone else shuts down.

It’s not just about surviving the chaos. It’s about profiting from it.

Example: A steel manufacturer using DROM could adjust cooling systems dynamically during heatwaves, reducing downtime and avoiding costly repairs. Competitors without predictive resilience tools might see extended shutdowns and increased emissions.

3. Reputation Matters More Than Ever

Consumers and investors aren’t just looking at your carbon footprint anymore. They want to know if your operation is built to last.

Adopting DROM demonstrates that you’re serious about sustainability—not just from an emissions standpoint, but from a resilience standpoint. And when regulations shift to include resilience metrics, you’ll already be ahead.

Example: A food and beverage company using DROM to protect its supply chain from drought-related disruptions could see its ESG score improve significantly, attracting investors looking for resilient, future-ready companies.

4. Continuous Improvement Means Continuous Gains

The beauty of DROM is that it never stops improving.

By using predictive analytics and continuous monitoring, you’re building a resilience system that learns from every disruption and gets stronger over time.

Every adaptation makes you better prepared for the next crisis. And every improvement adds to your competitive advantage.

Example: A chemicals company that continuously refines its resilience systems could cut energy consumption by 20% over five years, reduce Scope 3 emissions, and improve its carbon accounting accuracy.

Adapting Operations to Climate Volatility

The companies that survive the next decade will be the ones that understand a simple truth: Resilience shouldn’t be about building higher walls, but building smarter systems.

Those who act now will be the ones setting the standard. Those who don’t will be left wondering why their resilience strategies keep falling short.

The real question isn’t whether you’ll adapt. It’s whether you’ll do it before everyone else.

You Can’t Outbuild Climate Chaos—But You Can Adapt

You can’t control the weather. You can’t predict when the next drought, flood, or heatwave will hit.

But you can control how your systems respond.

And that’s what real resilience is all about. It’s not about reinforcing your infrastructure until it’s too rigid to adapt. It’s about creating systems that can respond, adjust, and improve, no matter what conditions they face.

The companies that adopt DROM now will be the ones thriving in the future.

They’ll be the ones with supply chains that stay operational during disruptions, energy systems that adapt to changing conditions, and resilience frameworks that learn from every challenge.

The ones who wait? They’ll be stuck fighting last year’s battles while everyone else moves forward.

Because here’s the truth: You can’t outbuild climate chaos. But you can outmaneuver it.

Every moment you wait is a moment you’re losing ground. And when the next wave of hydroclimate whiplash hits, the companies that act now will be the ones still standing.

It’s your move.

Know more at https://carbonminus.com/contact-us/

FAQs

Q: What exactly is hydroclimate whiplash?

It’s the rapid swing between extreme weather events—like droughts followed by floods—that disrupt supply chains, infrastructure, and resource availability in unpredictable cycles.

Q: Why aren’t traditional resilience strategies enough?

Because they’re reactive. They assume rare, predictable threats. Hydroclimate volatility demands dynamic systems that adapt in real-time.

Q: What’s the ROI of investing in adaptive resilience now?

Avoided downtime, reduced emissions, regulatory readiness, and reputational lift. Plus, long-term operational savings from smarter energy and resource use.

Q: Is DROM a tech platform or a methodology?

DROM is a strategic framework. CarbonMinus implements it using AI-driven monitoring, analytics, and integration tools tailored to your operations.

Q: Will regulators require resilience reporting soon?

Yes. CSRD, TCFD, and others are already evolving to include resilience metrics. Getting ahead now avoids costly future retrofits.