Key Takeaways

- The $2.3M Invisible Leak: Up to 40% of a foundry’s energy is lost to invisible waste like idle equipment and poor power quality, costing a typical operation over $2.3 million a year.

- The Aluminum Casting Penalty: Aluminum casting uses 381% more energy than iron, but most foundries are still using outdated, inefficient energy strategies that fail to account for this difference.

- The Smart Monitoring Fix: By implementing real-time, asset-level monitoring, leading foundries are cutting energy consumption by up to 25% and transforming a major liability into a powerful competitive advantage.

- ROI in Under 18 Months: Smart foundry energy optimization is not a cost center; it’s an investment that delivers a full ROI in under 18 months, unlocking significant annual savings and simplifying ISO 50001 compliance.

Why are their profit margins still silently eroding for plant managers in the global foundry market? In an industry set to cross $105 billion, it appears plant managers from Ohio to Gujarat are wrestling with the same frustrating puzzle.

They’ve meticulously optimized production schedules, squeezed every penny from raw material suppliers, and invested in furnace upgrades. They track uptime, output, and costs with military precision.

Yet their profit margins keep shrinking. Why?

Most attribute it to the usual suspects: volatile material prices and rising labor costs.

But what if the real culprit is something else entirely? What if the biggest financial leak in your operation isn’t on your balance sheet or in your supply chain?

What if it’s hiding in plain sight on your production floor?

Consider this perplexing fact: switching a single production line from iron to aluminum casting can increase its energy consumption by a staggering 381%. Every foundry manager accounts for the primary cost on their utility bill.

But almost all of them completely miss the secondary, and far more damaging, financial impact. It’s a cost that never appears on a standard energy audit.

What is this secondary impact, and why does it remain invisible to even the most experienced operators?

This is what we will unravel. This guide isn’t another checklist of obvious energy tips. It’s an investigation.

We will follow the trail of clues that most foundries overlook to expose the true source of this margin erosion.

Forget what you think you know about foundry energy optimization. We are going on a hunt for the hidden culprit that is quietly costing you millions.

The Hunt for the Energy Culprit: A Trail of Dead Ends

Every experienced foundry manager knows where to look first when energy costs spike: the melting furnace.

As the heart of the operation, it’s responsible for a massive 55% of a foundry’s total energy consumption. The conventional wisdom has always been straightforward: to cut energy costs, you must optimize the melt.

Foundries have spent billions on this logic, upgrading from older, less efficient cupola furnaces to modern induction furnaces, chasing incremental efficiency gains.

And yet, the puzzle remains.

Even foundries with the latest, most advanced melting technology watch in frustration as their energy bills continue to climb. They’ve followed the industry playbook to the letter by optimizing charge materials, fine-tuning melt cycles, and minimizing holding times.

They’ve tackled the biggest, most obvious energy consumer head-on. But they are still losing the battle. This leads to a critical question: If the problem isn’t the furnace itself, then what is it?

It’s a dead end. Focusing solely on furnace efficiency is like trying to fix a leaky bucket by polishing the handle. The real leaks are somewhere else entirely.

Let’s look at another clue: The bewildering challenge of aluminum.

As demand for lightweight components grows, more foundries are shifting production from iron to aluminum. On paper, the cost is clear: aluminum’s higher melting point requires more energy.

But the 381% increase in energy intensity per ton is a number so extreme it should be a major red flag. Most managers simply accept this as a fixed cost of doing business, trying to mitigate it by tweaking melt parameters.

But the financial damage remains. They are treating a symptom, not the disease.

Because if the two most obvious culprits, the furnace itself and the type of metal being melted, don’t fully explain the millions of dollars vanishing from the bottom line, what does?

We’ve hit a second dead end.

It seems the real source of the waste is not in how you melt, but in the dozens of unmonitored, invisible processes happening around the melt.

The foundries that will win in this growing market will be the ones that look beyond the obvious. They’ll be the ones who finally identify and stop the invisible leaks that their competitors continue to ignore.

So, where does the hunt lead us next?

To a place most operators see every day but never truly measure. It’s in the moments you’ve been trained to ignore: the quiet, unmeasured gaps between production cycles. The next clue is found by asking a deceptively simple question:

What is your equipment costing you when it’s doing nothing at all?

Cut holding Furnace Idle Time Energy Costs with Smart Controls

That question: What is your equipment costing you when it’s doing nothing at all? is where we find our first real clue.

The answer is staggering. For many foundries, as much as 40% of their total energy bill is consumed by equipment that is not actively producing anything.

This is the ghost in your machine: a multi-million-dollar energy drain happening during shift changes, on weekends, and in the quiet moments between production runs.

Individually, they seem like minor costs. But together, they create a constant, low-level hum of energy waste that bleeds your operation dry. One analysis found that idle equipment alone can account for up to a quarter of a facility’s entire energy consumption.

But idle time is only one of the invisible culprits. There’s another, even more stealthy drain on your profits: poor power quality.

Hidden on your utility bill are penalties for something called a low “power factor.” In simple terms, this is a fine your utility company charges you when your equipment uses energy inefficiently, creating electrical “sludge” in the system.

Most foundry owners and managers don’t even know they’re paying this penalty, yet it can add up to tens or even hundreds of thousands of dollars a year.

So why have these two massive sources of waste, idle energy and power quality penalties, remained invisible for so long?

Because you’ve been given the wrong tool for the job, relying on your main utility meter to find these leaks is like trying to find a needle in a haystack.

Your monthly bill tells you that you used a lot of energy, but it gives you zero information about how, where, or when it was wasted.

If the main meter is blind to these leaks, how can you possibly find them? You need to see your operation in a completely new way.

How Do Foundries Cut Energy Costs Without New Furnaces

The reason your best efforts have hit a wall is that you’ve been fighting an invisible enemy.

Your monthly utility bill tells you that you lost the battle for efficiency last month, but gives you zero clues about how to win it today.

The revolution in foundry energy optimization lies in shifting from historical guesswork to real-time visibility. The solution is asset-level energy monitoring solution for foundries: a network of smart sensors that act like a fleet of tiny, dedicated accountants, tracking energy consumption for every single piece of equipment in your facility, every second of the day.

It’s about giving your operation a nervous system. It’s how you can fix low power factor penalties in foundries without replacing furnaces and cut energy use by up to 25% to achieve a full ROI in under 18 months.

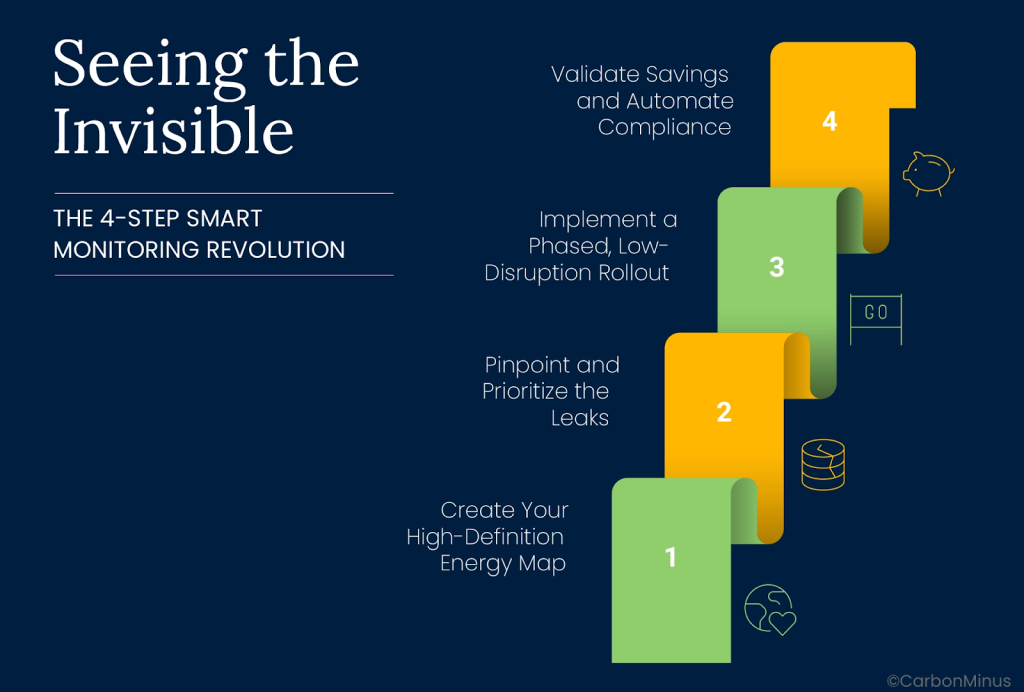

Here is the 4-step framework they use:

Step 1: Create Your High-Definition Energy Map

The first step is to attach smart sensors to your highest-consuming assets: your furnaces, compressors, and key production lines. Instantly, you get a live, high-definition map of your energy flow.

For the first time, you can see the “ghost load” of your idle equipment and fix low power factor penalties in foundries without replacing furnaces. The invisible becomes visible.

Step 2: Pinpoint and Prioritize the Leaks

With this new vision, you will no longer be wondering which foundry assets waste the most energy off shift because the waste has nowhere to hide. Your monitoring platform will automatically flag the biggest drains:

- The holding furnace that idles for three hours between shifts, wasting thousands.

- The air compressor that cycles on and off all weekend, leaking compressed air and money.

- The specific motor that’s creating poor power quality and driving up utility penalties. You stop guessing and start targeting your efforts where they will have the most financial impact.

Step 3: Implement a Phased, Low-Disruption Rollout

This isn’t a rip-and-replace overhaul. A smart implementation is a phased campaign. You start with the worst offenders identified in Step 2.

By tackling the biggest leaks first, you generate immediate savings that can fund the expansion of the monitoring system across your entire facility. It’s a self-funding cycle of continuous improvement that minimizes production disruption.

Step 4: Validate Savings and Automate Compliance

Every fix is instantly validated. The same system that finds the leak proves that you’ve fixed it, showing you the precise ROI in real-time on your dashboard.

This data-driven approach transforms your foundry energy optimization strategy from a cost center into a profit center. The granular data automates much of the reporting required for standards like ISO 50001, turning a tedious compliance burden into a simple, automated process.

With the framework you’re no longer hunting for ghosts because you’re giving yourself the power to see everything.

ROI Validation: The $144,000 Proof and Beyond

Theory is one thing, results are another. The most compelling reason to adopt this new way of seeing is the undeniable financial return.

This isn’t a ten-year infrastructure investment. Foundries implementing this strategy are seeing dramatic results, fast.

One well-documented case study showed that by identifying and correcting issues with their melting process and support equipment, a foundry was able to achieve $144,000 in annual energy savings.

Another facility, by focusing on optimizing its furnace charging and idle times through real-time monitoring, cut its energy consumption by a staggering 17%.

Smart energy management is no longer a sustainability initiative relegated to a corporate social responsibility report. It is one of the single most powerful levers a foundry can pull to directly impact its bottom line, protect itself from market volatility, and build a more resilient, competitive, and profitable operation.

From Surviving to Thriving

For decades, foundry operators have been forced to manage energy with one hand tied behind their backs.

The frustration of hitting an efficiency plateau, the mystery of eroding margins despite best efforts, and the slow bleed from invisible costs have been the accepted reality of a tough industry.

That era is now over.

The solution to the puzzle wasn’t a bigger, better furnace. It was a new way of seeing.

By making the invisible waste from idle equipment and poor power quality visible, asset-level energy monitoring solutions for foundries has turned a chronic, unsolvable problem into a straightforward, manageable opportunity.

It provides the tool to finally hunt down the ghosts in your machinery and reclaim the millions of dollars that were vanishing into thin air.

The choice is no longer between investing in production or investing in efficiency. Smart monitoring is an investment in production, profitability, and future-proofing your entire operation.

In a market that is only getting more competitive, the foundries that thrive will be the ones that work smarter.

Stop hunting for clues. It’s time to turn on the lights.

If you need help to understand how do foundries cut energy costs without new furnaces, reach out to us today – www.carbonminus.com. We have helped companies in heavy industries reduce the expenditure drastically with modern energy management solutions – https://youtu.be/uk9dUWPhYQ0

FAQs

1. Is installing an energy monitoring system disruptive to my operations?

No. A modern, phased implementation is designed for minimal disruption. Sensors can often be installed during planned maintenance or downtime to understand which foundry assets waste the most energy off shift to prove the concept before expanding.

2. My foundry is old. Will this technology work with my legacy equipment?

Yes. One of the primary benefits of asset-level monitoring is its ability to work with a wide range of equipment, both old and new. It can help you identify which legacy machines are the least efficient and provide a clear business case for either retrofitting or replacement.

3. What is the typical upfront cost of a smart monitoring system?

Costs can vary based on the size of your facility and the number of assets you want to monitor. However, many providers offer flexible pricing models, and because the ROI is so rapid (often under 18 months), the system typically pays for itself very quickly.

4. We already have a building management system (BMS). Isn’t this the same thing?

Not at all. A BMS typically controls HVAC and lighting at a building level. It does not provide the granular, real-time, asset-level data on production equipment (like furnaces, motors, and compressors) needed to uncover the deep inefficiencies discussed in this guide.

5. How quickly can I expect to see savings?

You can often identify low-hanging fruits like equipment left on overnight or during weekends within the first few days of monitoring. Significant savings from optimizing processes and correcting power factor issues can typically be realized within the first 3 to 6 months.

References

- https://www.credenceresearch.com/report/foundry-market

- https://www.foundrymag.com/melt-pour/article/21928478/seven-steps-to-energy-efficiency-for-foundri

- https://www.foundrymag.com/issues-and-ideas/article/21249875/to-protect-vulnerable-assets-optimize-power-quality-power-factors-september-2022

- https://news.bpx.co.uk/how-mitsubishi-electric-helped-a-uk-foundry-slash-energy-costs/

- https://focusonenergy.com/success-stories/waupaca-foundry-backs-up-its-competitiveness-with-energy-efficiency

- https://www.iso.org/iso-50001-energy-management.html