Key Takeaways

- Reactive maintenance costs 3x more than planned, predictive maintenance across renewable energy assets, silently eroding profit margins for most O&M providers.

- AI-driven predictive analytics has been proven to reduce unplanned downtime by 47% and slash annual operational costs by hundreds of thousands of dollars in large-scale solar installations.

- Reduce unplanned downtime in solar plants with predictive maintenance cutting overall maintenance costs by 25-30% and reduce equipment breakdowns by up to 75%, allowing service providers to scale operations five times faster than their reactive competitors.

- Leading providers are leveraging these savings and efficiencies to move beyond commodity pricing, justifying 15-20% higher service fees through demonstrable value and transparent, automated reporting.

Last year was a record-breaker for the solar industry. Global solar installations soared, pushing the Operations & Maintenance (O&M) market to an unprecedented $14.51 billion. By next year, it’s projected to cross $32 billion, representing a massive wave of opportunity. Yet, a strange paradox is unfolding: while the market booms, the vast majority of service providers are struggling.

Industry data reveals a startling trend: an estimated 80% of renewable service companies are failing to scale beyond regional operations. They are trapped in a cycle of high operational costs, intense pricing pressure, and shrinking profit margins. They hire more technicians, cut service fees, and work harder, but the needle refuses to budge.

What if the answer to scaling isn’t about working harder, but smarter? What if the top 20% of successful providers have discovered a fundamental shift that allows them to predict and prevent problems before they cripple their operations? This is a completely different approach to O&M that turns maintenance from a costly liability into a strategic advantage.

The secret lies in moving from a reactive to a predictive model. The question is, how are they doing it?

The Hidden Crisis: Why Traditional O&M Models Are Breaking

For many O&M providers, the daily reality is a high-stakes game of whack-a-mole. An inverter fails at a site 200 miles away. A string of panels goes offline without warning. A client calls, angry about underperformance they noticed before you did.

This is a symptom of a broken model.

The Scaling Trap Most Providers Fall Into

The traditional approach to solar O&M is fundamentally reactive, and this model has a built-in ceiling that prevents sustainable growth. Providers fall into three common traps:

- Manual Inspection Dependency: The industry still heavily relies on manual inspections, with some reports indicating as many as 80% of service providers are stuck in this reactive loop. This approach is not only labor-intensive and expensive but also impossible to scale. Doubling your portfolio means nearly doubling your field staff, leading to diminishing returns and logistical chaos.

- The Data Fragmentation Challenge: As portfolios grow, so does the complexity of managing them. Different sites use different inverters, various monitoring systems, and multiple data platforms. This creates data silos where crucial information is scattered and disconnected, making it impossible to get a single, unified view of asset health across the entire portfolio. You can’t optimize what you can’t see.

- The Unavoidable Cost Spiral: This reactive model forces you into a punishing cost spiral. Because you only fix problems after they occur, you are constantly paying for expensive emergency repairs, truck rolls, and rushed replacement parts leading to costs that are three times higher than planned maintenance.

The Numbers That Reveal the Problem

This is a verifiable crisis reflected in hard numbers.

- Performance Leaks: A staggering 20% of potential energy generation and revenue is lost to something as simple as dust and soiling, which requires constant, data-driven monitoring to manage effectively. Add to that an average annual panel degradation rate of 0.5-1%, and the losses compound quickly.

- The Price Squeeze: While your internal costs are spiraling up, the market is pushing service prices down. Intense competition has led to significant pricing pressure, forcing providers to offer more for less, directly squeezing already thin profit margins.

But what puzzled industry analysts is that some of the most successful providers who were scaling rapidly, were actually charging more. They had discovered something else entirely, a way to escape the reactive trap that their competitors were still caught in.

Market Opportunity: The $100M+ Scaling Framework

The reactive model isn’t just inefficient; it’s a strategic dead end in a market that is moving at lightning speed. While struggling providers are caught in the weeds of daily repairs, a massive, multi-billion-dollar opportunity is unfolding for those who can see the bigger picture.

Why Now Is the Perfect Storm for Predictive O&M

Three powerful forces are converging to create a once-in-a-generation shift in the solar O&M landscape:

- Explosive Asset Growth: The sheer volume of solar assets requiring maintenance is staggering. Global solar installations have skyrocketed, with total capacity now measured in terawatts. There has never been a larger portfolio of assets that desperately needs intelligent, efficient management. For example, predictive fault detection for PV strings inverters and combiner boxes.

- The Technology Has Arrived: For years, “predictive analytics” was a buzzword reserved for massive corporations with deep pockets. That has changed. The costs of IoT sensors, cloud computing, and advanced AI algorithms have plummeted, making these powerful tools accessible and cost-effective for solar O&M providers of all sizes for the first time in history.

- Maturing Client Expectations: Asset owners are no longer satisfied with basic reactive services. They are more sophisticated, demanding data-driven proof of performance, transparent reporting, and demonstrable ROI on their O&M investments. This shift in expectations makes predictive analytics not just a competitive advantage but a market necessity.

A Global Gold Rush for Savvy Providers

This is a global phenomenon creating distinct opportunities in key markets:

- In India: The solar market has experienced a phenomenal 3,450% growth since 2014, reaching over 100 GW of installed capacity. This rapid expansion has created a massive need for scalable O&M solutions that can keep pace.

- In the US: The market continues to show leadership in O&M volume, adding 13 GW of new capacity requiring maintenance services in a single year.

- In Emerging Markets: Regions like Latin America are demonstrating the fastest growth, with O&M markets expanding at an incredible 36% year-over-year, signaling a worldwide demand for advanced maintenance services.

The market is ripe for the taking. The capital is there, the assets are in the ground, and the demand for excellence is clear. Yet most providers are still fighting yesterday’s battles with outdated tools, while the winners have already moved on to tomorrow’s game.

So what does that game actually look like? It looks like real-world results and undeniable ROI.

The Solar O&M Predictive Analytics Revolution: Real Case Studies

Across the globe, forward-thinking operators are leveraging predictive analytics to achieve transformative results that leave their reactive competitors behind. These are game-changing improvements in efficiency, cost savings, and overall performance.

Arizona Success Story: From Reactive Chaos to Predictive Control

- The Challenge: A sprawling 75MW solar installation in Arizona was plagued by unpredictable maintenance costs and frequent, costly downtime. Technicians were constantly reacting to failures, with an average response time of 72 hours for critical issues.

- The Solution: The operator deployed an AI-driven predictive maintenance platform to monitor the plant’s assets in real time, using machine learning to detect subtle anomalies that preceded equipment failure.

- The Results: The impact was immediate and dramatic. The facility achieved a 47% reduction in unplanned downtime, and operational savings topped $425,000 annually. Most impressively, the average response time for critical maintenance alerts plummeted from 72 hours to just 4 hours, allowing technicians to fix problems before they could escalate.

University of California: Maximizing Energy Yield and Efficiency

- The Challenge: A university system with significant solar assets was struggling to maximize its energy generation due to reliance on traditional, schedule-based maintenance, which often missed developing issues.

- The Solution: By implementing AI-driven predictive protocols, the university was able to analyze performance data and identify underperforming assets in real time, moving from a “best guess” to a data-driven maintenance strategy.

- The Results: The shift led to a 27% increase in overall energy yield and a 15% reduction in downtime, directly boosting the financial return on their solar investments and proving the power of predictive optimization.

European Multi-Site Study: Preventing Failures at Scale

- The Challenge: An asset manager overseeing multiple solar facilities across Europe faced the complex task of optimizing performance across a geographically diverse and technologically varied portfolio.

- The Solution: Machine learning algorithms were deployed to analyze data from across all sites, identifying patterns and predicting potential failures before they occurred.

- The Results: The program was a resounding success, preventing an incredible 89% of potential failures and leading to a 31% improvement in operational efficiency. Over three years, the initiative saved the company a documented €2.3 million in maintenance costs and lost production.

The pattern was clear. Across different geographies, scales, and operating conditions, predictive analytics delivered undeniable results. But the breakthrough wasn’t in adopting the technology itself. It was in how these successful operators implemented it. They followed a structured framework that turned raw data into actionable, profitable insights.

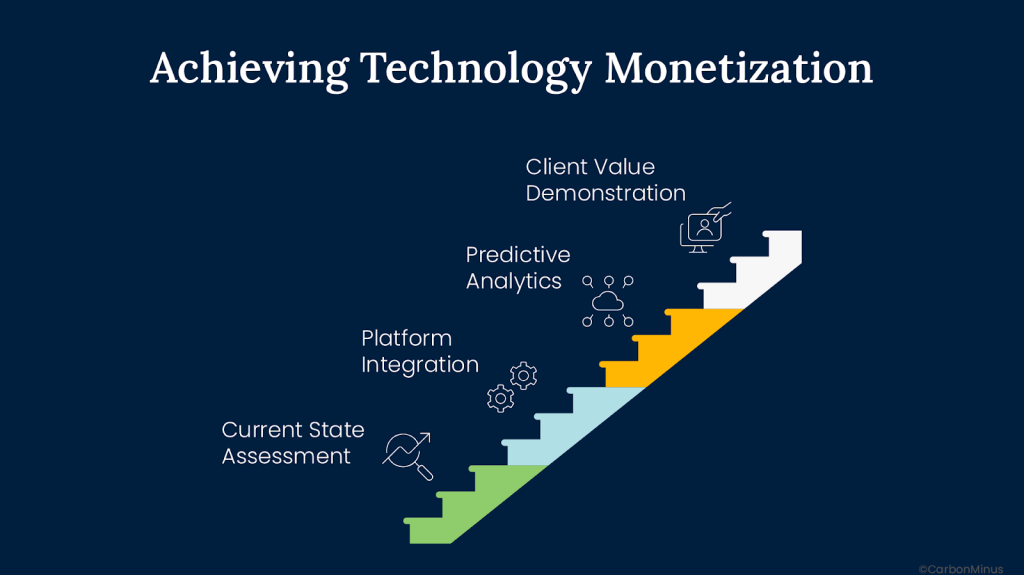

Technology Implementation Framework: The 4-Stage Scale Model

The successful operators adopted a new operational philosophy rather than betting on a new software. They followed a disciplined, four-stage framework to transform their business from the ground up.

This methodical approach is precisely what allows them to unlock the full potential of predictive analytics and achieve scalable, profitable growth.

This is where the 20% who succeeded did something radically different from the 80% who failed.

Stage 1: Current State Assessment & Digital Foundation

Before you can build the future, you must understand the present. This foundational stage is about conducting a brutally honest audit of your current operations.

- Map Your Data Streams: Identify every source of data across your portfolio like inverters, string monitors, weather stations, and maintenance logs. The goal is to pinpoint every data silo and source of fragmentation.

- Calculate Your True Reactive Costs: Go beyond surface-level expenses. Quantify the costs of emergency truck rolls, technician overtime, lost production during downtime, and inventory carrying costs for emergency parts. This number is almost always shockingly higher than leaders assume.

- Establish Performance Baselines: Using your existing data, establish clear benchmarks for asset performance, degradation rates, and maintenance intervals. This data will become the yardstick against which you measure all future improvements.

Stage 2: Platform Integration & Centralization

With a clear understanding of your starting point, the next stage is to break down the data silos and create a single source of truth.

- Deploy a Centralized Dashboard: The goal is to create one unified platform that provides a comprehensive, real-time view of every asset in your portfolio, regardless of its location or the OEM equipment used.

- Integrate Disparate Systems: This is a critical step where a powerful energy analytics platform like CarbonMinus shines. It ingests data from your various monitoring systems and normalizes it, allowing for true apples-to-apples comparisons across your entire fleet.

- Enhance Data Collection: Where necessary, deploy smart IoT sensors to fill data gaps and provide the granular, high-frequency data needed for accurate predictive modeling.

Stage 3: Solar O&M Predictive Analytics Deployment

This is where the transformation from reactive to predictive happens. With a clean, centralized data stream, you can now apply machine learning algorithms to unlock actionable insights.

- Activate AI-Driven Scheduling: The platform’s algorithms analyze asset performance data, weather forecasts, and historical failure rates to move you from a fixed maintenance schedule to an optimized, dynamic one. Technicians are dispatched based on data-driven need, not a blind guess.

- Enable Early Warning Systems: The system learns the unique “heartbeat” of each asset and automatically flags subtle deviations that indicate a developing fault, long before it triggers a critical failure alarm.

- Forecast Performance and Failures: The platform doesn’t just tell you what’s happening now. It predicts what will happen next. It forecasts energy generation with high accuracy and identifies which components are at the highest risk of failure, allowing you to prioritize resources effectively.

Stage 4: Client Value Demonstration & Monetization

This final stage is what truly separates the leaders from the pack. It’s about using this powerful new capability to fundamentally change your relationship with clients and your position in the market.

- Automate Reporting and Transparency: Replace outdated monthly PDFs with real-time, dynamic dashboards for your clients. Give them transparent access to their asset performance, the maintenance activities you’ve performed, and the value you’re delivering.

- Document and Prove ROI: Use the platform to generate reports that explicitly document the ROI of your service, showing increased uptime, improved energy yield, and quantifiable cost savings from prevented failures.

- Shift from Commodity to Value-Added Partner: Armed with this data, you are no longer just another maintenance vendor competing on price. You are a strategic partner helping clients maximize their asset value. This is how you justify higher service fees, secure longer-term contracts, and build a powerful competitive moat around your business.

The ROI Mathematics: Why Solar O&M Predictive Analytics Pays for Itself

For any business leader, the most critical question is: What’s the return on this investment? The financial case for predictive analytics in solar O&M is overwhelmingly positive.

The technology pays for itself through a powerful combination of cost reduction, revenue enhancement, and improved scalability.

Deep Cost Reduction Metrics

The most immediate impact is on your operational expenses. By shifting from a reactive to a predictive model, you systematically eliminate the biggest cost drivers in your business.

- Slash Maintenance Costs: Case studies consistently show that it’s possible to reduce unplanned downtime in solar plants with predictive maintenance by 25-35%. This comes from optimizing technician schedules, reducing unnecessary site visits, and catching issues before they require expensive, large-scale repairs.

- Drastically Cut Downtime: The financial drain from unplanned outages is enormous. Predictive analytics has been proven to reduce unplanned downtime by up to 70%, keeping your clients’ assets generating revenue and avoiding performance-related penalties.

- Extend Equipment Lifespan: By monitoring equipment health and addressing minor issues proactively, you reduce wear and tear on critical components like inverters and trackers. This can extend the operational lifespan of your assets by 20-25%, deferring costly capital replacements and maximizing long-term value.

Significant Revenue Enhancement

Beyond just cutting costs, predictive analytics actively helps you generate more revenue both for your clients and for your own business.

- Optimize Performance and Generation: Smart analytics can boost annual energy production by 3-5% simply by optimizing cleaning schedules based on real-time soiling data and weather forecasts. For a large-scale plant, this translates into a significant revenue uplift such as through predictive fault detection for PV strings inverters and combiner boxes.

- Increase Client Retention and Value: When you can provide clients with transparent reports showing exactly how you’ve increased their uptime and boosted their energy yield, your service becomes indispensable. This locks in long-term contracts and drastically reduces client churn.

- Justify Premium Pricing: With a proven, data-backed value proposition, you can confidently command 15-20% higher service fees than competitors stuck in the reactive, low-price commodity trap. You are no longer selling a cost; you are selling a guaranteed return.

Unlocking Profitable Scalability

Perhaps most importantly, predictive analytics breaks the linear relationship between portfolio growth and operational cost. It allows you to scale profitably in a way that is impossible with manual models.

- Boost Labor Efficiency: With optimized scheduling and remote diagnostics, you can significantly reduce the need for manual inspections, leading to a 40% decrease in associated labor costs. Your existing team can manage a much larger portfolio of assets without being overworked.

- Enable Centralized Remote Management: A unified platform allows a small, centralized team to monitor a vast, geographically distributed portfolio. This unlocks the ability to expand into new regions without the massive overhead of setting up new operational hubs.

- Create Operational Leverage: As you add new assets to the platform, the incremental cost is minimal. The system scales effortlessly, allowing your revenue to grow much faster than your operational expenses, the true definition of a scalable business model.

Competitive Advantage: The Differentiation Framework

In a crowded market, the only sustainable advantage is to be different. Solar O&M predictive analytics allows you to fundamentally transform your service model and create a powerful competitive moat that insulates you from the price wars that plague the rest of the industry.

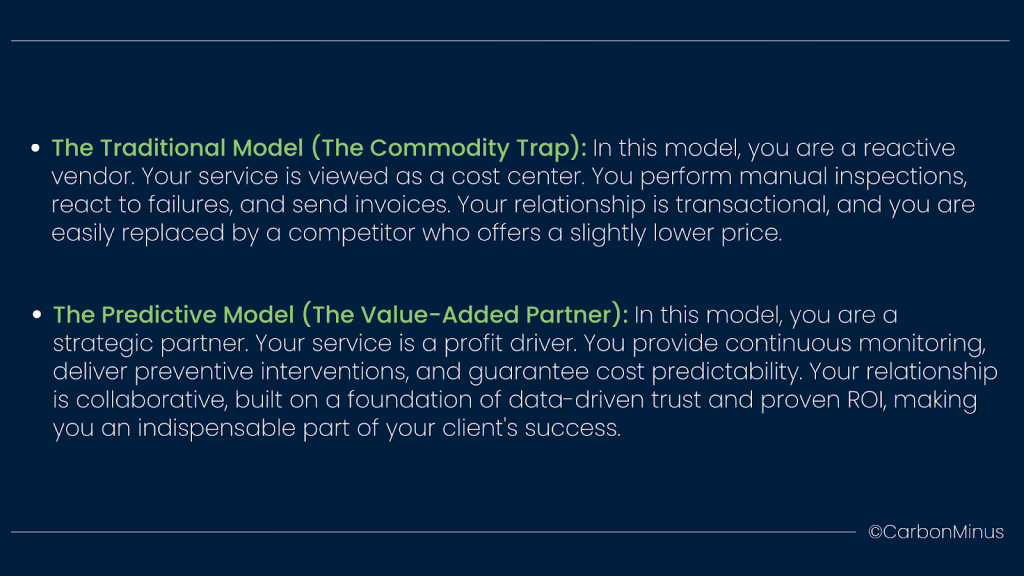

From Reactive Vendor to Predictive Partner

This technology enables a complete evolution of your business model and your relationship with clients.

Building an Unbeatable Market Position

This transformation allows you to reposition your entire company in the market.

- Rewrite Your Value Proposition: You are no longer just “maintaining” assets; you are “optimizing asset value.” This shift allows you to move beyond commodity pricing and structure your contracts around the value you deliver: shared savings, performance guarantees, and uptime commitments.

- Educate the Market: Use the transparent, automated reports from your platform to educate your clients. Show them the tangible financial benefits of your service. When clients understand the ROI you provide, price becomes a secondary consideration.

- Create a Technological Moat: While your competitors are still trying to hire enough technicians to keep up, you are scaling with technology. This creates a significant barrier to entry and a competitive advantage that is difficult and expensive for others to replicate.

Implementation Roadmap: Your 90-Day Transformation Plan

Transitioning to a predictive model is a strategic initiative, but it doesn’t have to be a multi-year ordeal. With a focused approach, you can achieve a dramatic transformation in just one quarter.

Days 1-30: Foundation and Planning

- Conduct Your Assessment: Perform the detailed audit of your current operations as outlined in the framework. Identify your pilot sites and establish your baseline performance metrics.

- Select Your Technology Partner: Choose a platform like CarbonMinus that specializes in integrating disparate data sources and providing powerful, user-friendly solar O&M predictive analytics tools.

- Define Success Metrics: Establish clear, quantifiable goals for the pilot program (e.g., reduce truck rolls by 20%, improve response time by 50%).

Days 31-60: Deployment and Integration

- Install Hardware (If Needed): Deploy any necessary IoT sensors on your pilot sites to ensure a rich, high-frequency data stream.

- Integrate the Platform: Work with your technology partner to connect all your data sources to the centralized dashboard. Begin collecting and normalizing data, like SCADA CMMS integration for predictive work orders in solar O&M.

- Train Your Core Team: Get your key operational staff comfortable with using the new platform, interpreting its insights, and acting on its recommendations.

Days 61-90: Optimization and Scaling

- Validate the Algorithms: Let the platform’s machine learning algorithms train on your initial data. Compare the system’s predictions with real-world outcomes to validate its accuracy.

- Launch Your First Predictive Dispatches: Begin using the platform’s insights to schedule maintenance activities and prove the model’s effectiveness.

- Prepare Client-Facing Reports: Use the platform to build your first set of automated, transparent performance reports. Prepare to present these powerful new insights to your pilot client.

The secret the successful 20% discovered was about implementing it with discipline and speed, timing their transformation perfectly to capture the market’s momentum.

Future-Proofing Your O&M Business

The pace of innovation isn’t slowing down. Adopting predictive analytics today is about building a foundation that allows you to stay ahead for years to come.

Technology Trends to Watch

- Advanced AI and Digital Twins: AI will become even more sophisticated, enabling the creation of “digital twins” which are virtual replicas of your physical assets, that allow for even more accurate failure prediction and simulation.

- Drone and Robotic Inspection: Solar O&M predictive analytics will integrate seamlessly with autonomous drones and robotic inspection tools, further automating the process of data collection and physical maintenance.

- Blockchain for Transparency: Blockchain technology may be used to create immutable, auditable records of maintenance activities and performance data, providing unparalleled transparency for asset owners and investors.

Market Evolution Predictions

- Accelerated Consolidation: The gap between the tech-enabled leaders and the reactive laggards will widen, leading to further market consolidation.

- Increased Client Sophistication: As asset owners become more accustomed to data-driven insights, their demands for transparency and proven performance will become standard.

- Evolving Regulatory Requirements: Governments and regulatory bodies will likely begin to mandate higher standards for performance and reliability, making predictive capabilities a requirement for compliance.

The Choice That Defines Your Future

Two roads diverged in a wood and there stood the solar O&M industry with a choice to make.

The path of traditional, reactive maintenance leads to a future of shrinking margins, intense competition, and a constant struggle to scale. It’s the path that 80% of the industry is currently on.

But there is another path. It’s a path defined by data, intelligence, and foresight. It leads to higher profits, delighted clients, and a truly scalable business model. It is paved with predictive analytics and a commitment to operational excellence. This is the path the top 20% are taking.

The window of opportunity to make this transition is open now, but it won’t stay open forever. The early adopters are already building their competitive moats, capturing market share, and setting a new standard for performance.

The choice is yours. Will you remain in the struggling majority, or will you join the ranks of the predictive pioneers who are defining the future of energy?

Know more about the impact of solar O&M predictive maintenance on reducing operational costs and increasing energy savings. Visit www.carbonminus.com. We have helped companies reduce their cost and become more energy efficient despite their energy-intensive processes. Know all about it here – https://youtu.be/uk9dUWPhYQ0

FAQs

How long does it really take to implement a predictive analytics system?

Our 90-day transformation plan is a realistic timeline for a pilot deployment. Full-fleet integration can be phased over 6-12 months, with value being generated from the very first quarter.

Is this affordable for a mid-sized O&M provider?

Absolutely. Modern SaaS models make this technology highly affordable. The focus should be on ROI as our platform typically delivers cost savings that far exceed its subscription fee, often within the first year.

Will this system integrate with my existing monitoring tools?

Yes. Platforms like CarbonMinus are designed to be technology-agnostic. They excel at integrating with a wide variety of inverters, sensors, and legacy software to create a single, unified view.

What if my team isn’t tech-savvy?

The best platforms are designed with a user-friendly interface. The goal is to provide clear, actionable insights, not complex data science problems. We provide comprehensive training and support to ensure your team is confident and effective.

Reference

- https://www.precedenceresearch.com/solar-panel-operation-and-maintenance-market

- https://www.linkedin.com/pulse/solar-operations-maintenance-persistent-challenges-opportunities-m-no6we

- https://www.npws.net/blog/renewable-energy-scaling-challenges

- https://iea-pvps.org/wp-content/uploads/2022/11/IEA-PVPS-Report-T13-25-2022-OandM-Guidelines.pdf

- https://unisunpowersolutions.com/top-7-challenges-in-starting-a-solar-business/

- https://www.moserbaersolar.com/uncategorized/smart-solar-how-ai-powered-predictive-maintenance-is-revolutionizing-pv-system-performance/

- https://www.solarfeeds.com/mag/understanding-the-role-of-predictive-analytics-in-solar-energy-management-systems/

- https://www.residentialsolarpanels.org/uncategorized/smart-solar-maintenance-how-ai-cuts-your-panel-service-costs/