Many of the futuristic movies we have seen in Hollywood usually have a scene where a scientist is standing at the edge of a lab, watching some state-of-the-art tech make some mind-blowing discovery.

It’s a separate issue that a notorious villain later steals that tech and threatens to destroy the world. But coming back to the point at hand.

That tech we used to see only in movies is now becoming an integral part of our lives —- crunching through millions of data points. In hours, it identifies sustainable materials that are lighter than steel, tougher than titanium, and produced with far less carbon.

This is Generative AI. And it’s increasingly being used for material science.

From Trial and Error to Predictive Modeling

For decades, developing new alloys relied on trial, error, and patience. Researchers mixed elements, tested properties, and repeated the cycle endlessly. Now, AI is changing the game. Generative models use massive datasets and simulation tools to create alloys with properties tailored to exact needs, cutting years of development into days.

What We’ll Explore

In this blog, we’ll look at how generative AI is revolutionizing material science. From designing alloys that reduce carbon emissions to creating smarter, more efficient processes.

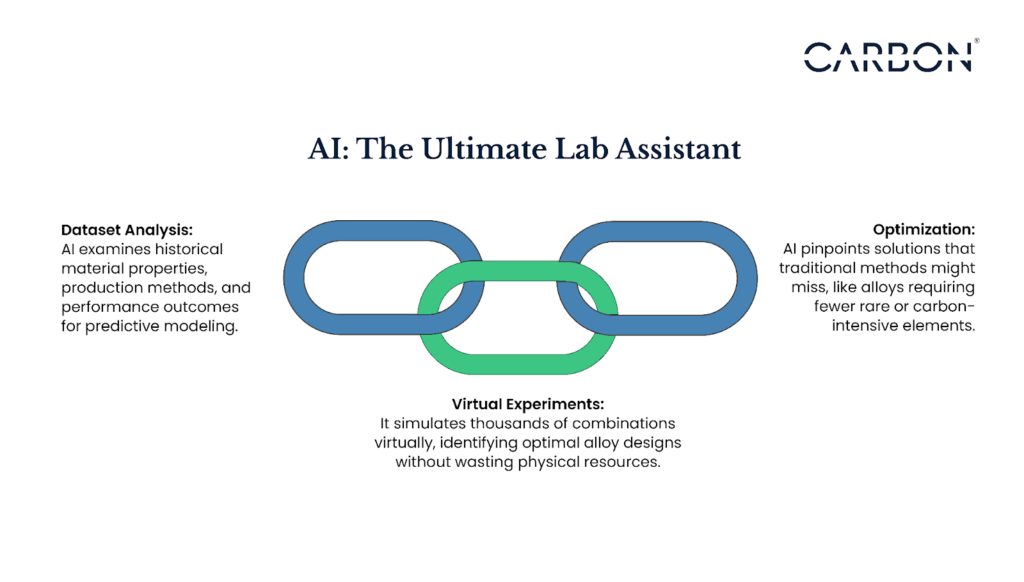

AI: The Ultimate Lab Assistant

Do you have a lab assistant who never gets tired, works 24/7, and can run thousands of experiments in minutes? Now you do. Generative AI analyzes massive datasets, predicts the best combinations of elements to achieve specific properties, and creates sustainable materials that are lighter and stronger.

AI models operate on a simple yet powerful principle: data-driven predictions. Here’s how:

- Dataset Analysis: AI examines historical material properties, production methods, and performance outcomes for predictive modeling.

- Virtual Experiments: It simulates thousands of combinations virtually, identifying optimal alloy designs without wasting physical resources.

- Optimization: AI pinpoints solutions that traditional methods might miss, like alloys requiring fewer rare or carbon-intensive elements.

What is A Smart Alloy?

Here’s where AI truly shines: its ability to uncover unexpected solutions. For example:

- Designing an alloy that uses less cobalt, a rare and ethically challenging material.

- Identifying a combination of metals that reduces production emissions.

- Suggesting alternatives that improve strength while cutting material costs.

Why This Matters

By reducing trial and error, cutting resource waste, and optimizing designs for sustainability, AI helps industries meet the growing demand for smarter, greener materials. That too quickly.

AI Meets Industry Challenges

Generative AI makes it possible to design sustainable materials that make vehicles lighter, airplanes more efficient, and buildings more eco-friendly—all while cutting emissions. And multiple industries from automotive to aerospace are already reaping the benefits.

Automotive Innovations

Car manufacturers are leading the charge in using generative AI to design lightweight alloys that transform performance:

- Hyundai’s G80 Electrified: Partnering with NVIDIA, Hyundai reduced drag by 7.9%, boosting driving range by 50 miles.

- Volkswagen’s Retro Microbus: By redesigning wheels with AI, VW made them 18% lighter, improving rolling resistance and cutting development time from 1.5 years to just months.

Aerospace Achievements

Aerospace companies are also turning to lightweight materials to reduce fuel consumption and emissions:

- Boeing’s Efficiency Gains: A 20% weight reduction in the Boeing 787 led to a 10-12% improvement in fuel efficiency.

- Advanced Aluminum Alloys: Making up 70-80% of civil aircraft weight, these alloys offer unmatched strength-to-weight ratios and corrosion resistance.

The EV Revolution

Electric vehicles (EVs) face unique challenges, especially the weight of batteries and motors. Generative AI is stepping in to:

- Offset battery weight with lightweight components.

- Enable smaller, more cost-effective batteries.

- Improve range and efficiency, making EVs more practical and accessible.

Lighter Materials, Bigger Savings

The impact of weight reduction is also measurable:

- Reducing vehicle weight by 10% improves fuel economy by 6-8%.

- Lightweight materials could save over 5 billion gallons of fuel annually by 2030.

Why It Matters

By designing smarter, lighter, and sustainable materials, generative AI is helping industries tackle one of their biggest challenges: reducing emissions without compromising performance. It’s a game-changer for businesses committed to both innovation and sustainability.

Your Opportunity to Lead the Change

By enabling rapid simulations and data-driven insights, GenAI is making it possible to design materials that outperform traditional alloys in strength, sustainability, and cost-efficiency.

Here’s the untapped potential:

- Carbon Footprint Reduction: Generative AI helps develop alloys that require less energy-intensive processing, cutting emissions from the start.

- Resource Efficiency: It identifies alternatives to rare metals, reducing environmental impact and supply chain dependencies.

- Circularity Integration: AI-designed sustainable materials are easier to recycle, supporting closed-loop manufacturing systems that reduce waste.

Are you ready to unlock the full potential of AI in your operations? Contact us today to explore how we can transform your sustainability strategy with AI-powered insights.

Book a demo at www.carbonminus.com