Key Takeaways

- Water use drives major Scope 3 emissions

- Treatment, heating, and cooling burn hidden energy

- Most companies fail to track these emissions

- Scope 3 gaps create financial and compliance risks

- Real-time monitoring unlocks visibility

- Predictive maintenance cuts waste before it hits

- Optimization delivers fast, measurable results

- Renewable energy reduces water-related carbon load

- CarbonMinus connects the full water-emission cycle

You’re chasing down every leak you can find, scrutinizing every line item on your carbon ledger, optimizing energy use, retrofitting equipment, slashing Scope 1 and Scope 2 emissions like your future depends on it.

But water? It’s hiding in plain sight.

Most industries are drowning in their own blind spots. They focus so hard on direct emissions that they ignore the silent heavyweight of carbon output—water use.

And it’s not just about turning on a faucet or running a pipe. Every drop that gets pumped, treated, heated, or cooled leaves a carbon trail.

Water treatment, water heating, water cooling—these processes burn energy like it’s going out of style. But because the emissions don’t show up on the factory floor or in the company’s immediate operations, they slip through the cracks.

They fall under Scope 3, the category everyone knows is important but no one’s really tackling.

It’s a problem. And it’s huge.

Industries like steel, chemicals, textiles, and food and beverage are missing the mark by ignoring the carbon cost of water. Every cubic meter of water consumed can generate about 10.6 kg of CO₂.

Multiply that by millions of cubic meters, and you’re looking at a mountain of emissions hiding right under your nose.

You can’t fix what you’re not tracking. And right now? The data is crystal clear: Water is your biggest unseen liability.

In this article, we’ll show you how water use contributes to Scope 3 emissions, why it’s so easy to overlook, and what you can do to stop the bleeding.

Because here’s the thing, those hidden emissions aren’t just a regulatory risk. They’re an opportunity.

The Emissions You Can’t See Are Costing You

You’re counting carbon molecules like your life depends on it. Every ton of CO₂ that slips through your fingers feels like a crack in your sustainability armor.

You’ve got Scope 1 and Scope 2 emissions pinned down with precision. But Scope 3? It’s the mess you never see coming.

And when it comes to water? That mess is huge.

Let’s break it down.

Scope 3 emissions cover everything indirectly connected to your operation, the stuff that doesn’t come from your own smokestacks or boilers but still adds up.

And the worst part? Water-related emissions are practically built to hide in Scope 3.

Here’s what you’re missing:

- Water Treatment: Every time you treat water, whether it’s filtration, desalination, or chemical dosing, you’re burning energy. Lots of it. And that energy use is generating CO₂ emissions you’re not tracking.

- Water Heating: Boiler feedwater systems, steam generation, industrial washing—every time you heat water, you’re pumping out carbon. And those emissions are usually buried under third-party processes.

- Water Cooling: Cooling towers, refrigeration systems, and condensers are all burning electricity to keep operations from melting down. But the emissions tied to these processes? They’re lumped into Scope 3 like an afterthought.

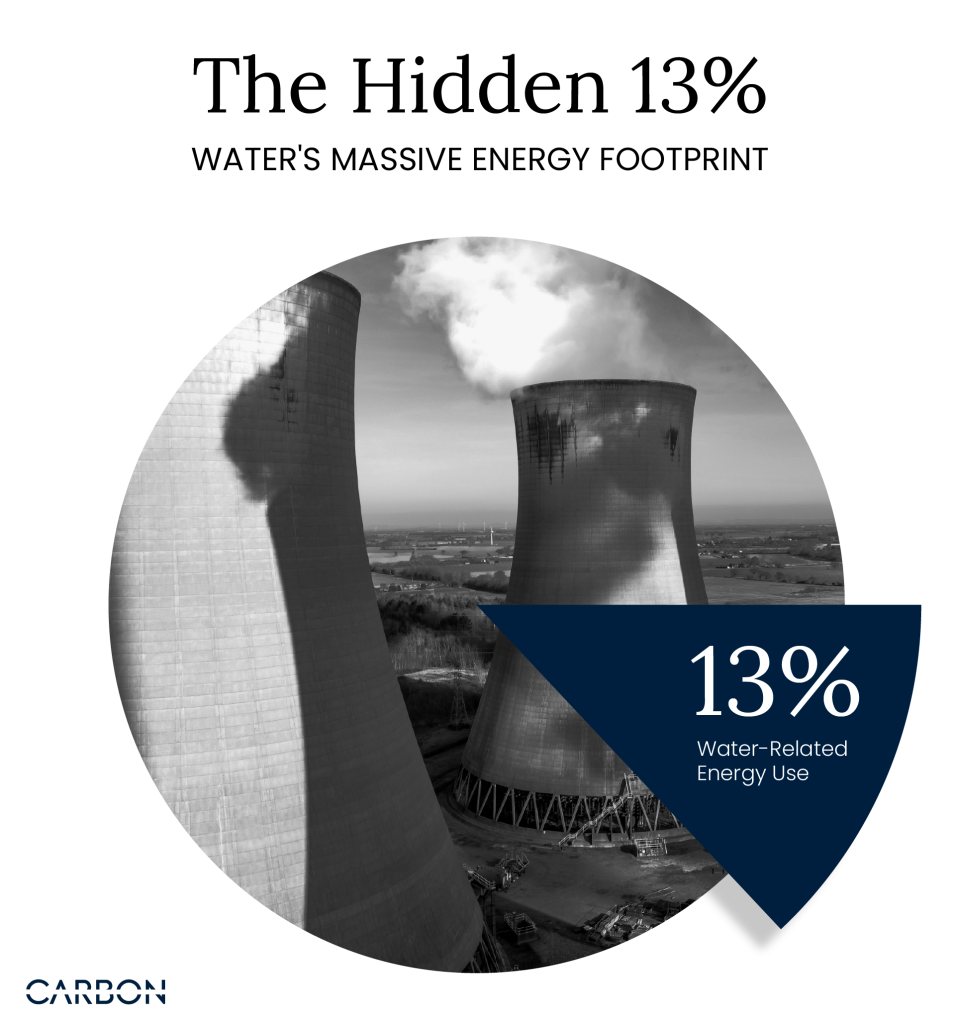

Here’s the kicker. Water-related energy use accounts for approximately 13% of U.S. electricity consumption.

That’s not a typo. Thirteen percent.

Now, consider how much of that energy is getting burned up in industrial processes. Every time a cooling tower spins or a boiler fires up, you’re churning out emissions most companies never bother to count.

And it gets worse. According to the EPA, each cubic meter of water consumed generates about 10.6 kg of CO₂. It’s the hidden carbon trail running through your entire operation.

But why do so many companies miss it?

Because Scope 3 emissions are designed to be invisible. They’re indirect, spread out, and tangled up in processes nobody wants to unravel.

Especially when those processes are buried under contracts with water suppliers or outsourced treatment systems.

This isn’t just a technical problem. It’s a psychological one.

- The Curse of Knowledge: You’re trained to focus on direct emissions because that’s what’s easy to measure. The stuff you can see, touch, and quantify. Water-related emissions? They’re abstract, buried, and overlooked.

- Social Proof: If everyone else is ignoring them, why wouldn’t you? If your competitors aren’t getting dinged for water-related Scope 3 emissions, it’s easy to assume you won’t either.

- Goodhart’s Law: What gets measured gets managed. But when your measurements leave out entire systems, your carbon management plan is built on a foundation of sand.

Here’s the reality: If you’re not counting water-related emissions, you’re not counting your real carbon footprint. And the longer you ignore it, the worse it gets.

Steel. Chemicals. Textiles. Food and Beverage. These industries burn through water like it’s free. And every gallon that gets pumped, treated, heated, or cooled leaves a carbon scar.

The EPA estimates that the U.S. industrial sector uses over 18.2 billion gallons of water per day. Imagine the carbon footprint tied to that volume. Then imagine how much of it goes completely unreported.

Water isn’t just a resource. It’s a liability. And right now, it’s a liability you’re not even tracking.

The Real Cost of Staying in the Dark

You can’t solve a problem you refuse to see. And when it comes to water-related emissions, most industries are still flying blind.

Why? Because the emissions are tangled up in the parts of your operation you rarely think about.

The hidden energy it takes to treat, heat, or cool water doesn’t fit neatly into the usual carbon accounting boxes. So, it gets ignored. Pushed off to Scope 3 and buried under a pile of indirect processes.

But just because it’s out of sight doesn’t mean it’s not costing you.

Every time you overlook the carbon tied to water use, you’re setting yourself up for financial risk, reputational damage, and compliance headaches that could’ve been avoided.

Here’s what it looks like when the numbers catch up with you:

- Missed Scope 3 Emissions: When you fail to count the energy used for water processes, your carbon reporting is incomplete. It’s not just an oversight, it’s a credibility gap. And if regulators catch it before you do, that’s a penalty waiting to be levied.

- Financial Exposure: Water-related processes aren’t just energy-intensive; they’re expensive. The more energy you burn through untracked water use, the more money you’re throwing away. And as energy prices climb, so do your losses.

- Reputation Damage: Companies that overpromise and underdeliver on sustainability targets end up on the wrong side of headlines. And if your Scope 3 accounting is missing a critical piece of the puzzle, it’s only a matter of time before someone calls you out on it.

Everyone’s chasing net-zero emissions targets, but the ones who get there first will be the ones who see the whole picture.

Right now? Most of your competitors are stumbling around with blinders on.

You have the chance to do better.

But only if you’re willing to look where others refuse to.

How to Reduce Scope 3 Emissions from Water Use

After all the doom and gloom, here’s the good news: Once you start tracking water-related emissions, you can cut them down faster than you think.

Most companies have their heads down, grinding away at Scope 1 and Scope 2 because that’s what the frameworks reward. Meanwhile, Scope 3 emissions tied to water use are left untouched—like loose threads in an otherwise clean-cut operation. But pulling on those threads? That’s where the real opportunity lies.

The ones who figure this out will lead. The rest will keep playing catch-up.

Start With the Right Tools

You need clarity before you can fix anything. And clarity starts with real-time monitoring.

If you’re still running on outdated data reports that take weeks to compile, you’re already behind. What you need is a system that’s not just watching but analyzing every drop of water you use 24/7.

AI-driven systems are changing the game. Instead of relying on manual audits or rough estimates, you get live feedback on everything from water intake to wastewater discharge.

And that means you can pinpoint inefficiencies before they turn into problems.

But monitoring alone isn’t enough.

Get Ahead With Predictive Maintenance

Most companies treat water systems like fire alarms. They only think about them when something breaks.

But waiting for problems to announce themselves? That’s burning money and burning carbon.

Predictive maintenance changes that. It’s about anticipating failures, not reacting to them. When you combine predictive analytics with real-time monitoring, you can see inefficiencies building up before they cause damage.

A chiller that’s pulling more power than it should? Fix it before it becomes an energy hog.

A cooling tower that’s about to clog up? Clear it before it sends your energy bills through the roof.

Every malfunction you prevent is a step closer to real carbon reduction. And the best part? It’s all measurable.

Optimize Your Systems. Then Optimize Again.

You don’t just fix problems. You make sure they never come back. And that takes optimization.

Water-related processes are notoriously inefficient. Old pumps, boilers, chillers, and cooling towers are almost never running at peak efficiency.

And the more outdated your systems, the higher your carbon costs.

Here’s what optimization looks like:

- Process Efficiency: Streamlining water use in every part of your operation. Cutting out unnecessary steps, rerouting water where it’s most needed, and recycling whenever possible.

- Equipment Upgrades: Swapping out outdated pumps, boilers, and chillers for newer, energy-efficient models. It’s an upfront investment, sure. But the payoff is massive.

- Predictive Analytics: Using AI tools to constantly fine-tune your operations. If something’s burning more energy than it should be, you know about it before it becomes a problem.

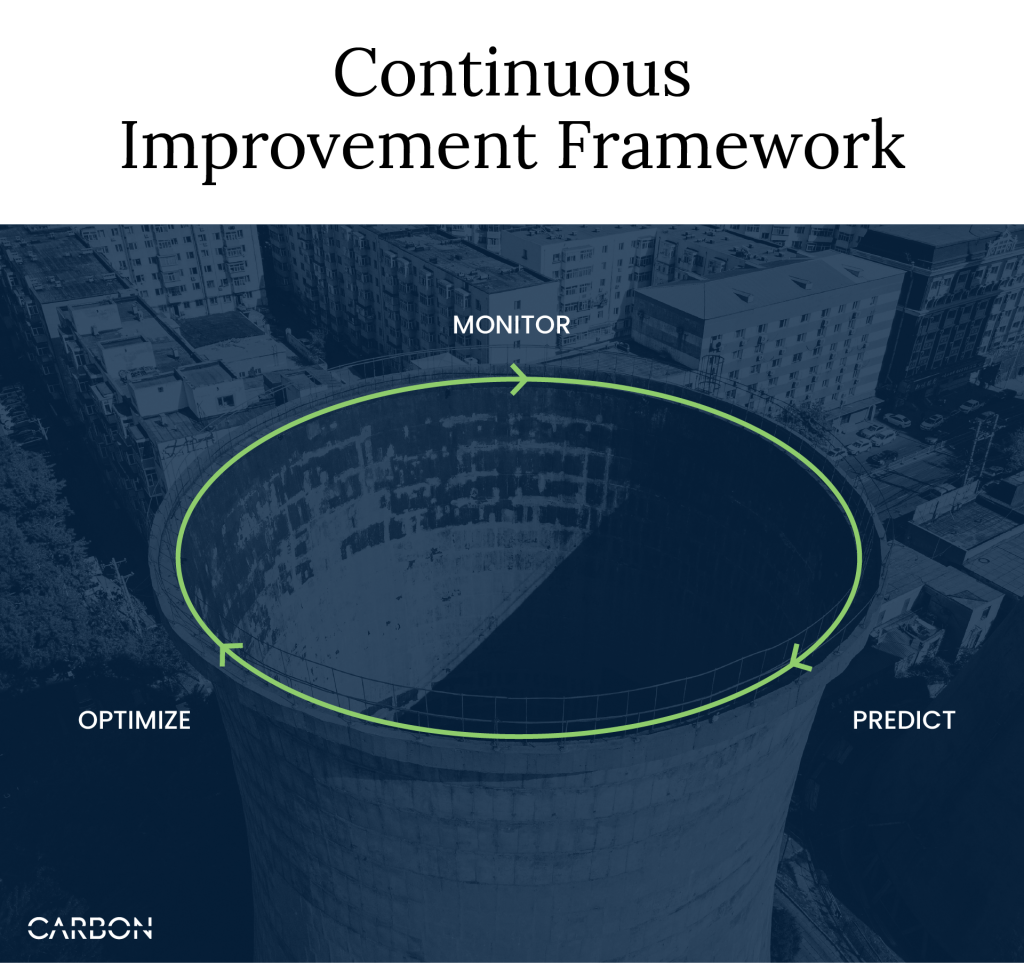

The goal is to create a feedback loop that never stops improving. Monitor. Predict. Optimize. Repeat.

Power Your Water Processes With Renewable Energy

Here’s the next level: Using green energy to power your water-related processes.

When you run your water heating, cooling, and treatment systems on renewables, you’re not stopping at cutting emissions, but reducing them as much as possible. Solar, wind, and hydropower are all options depending on your operation’s size and location.

And if you think renewables are just for Scope 1 and Scope 2, think again. If you’re outsourcing water processes to third-party providers, you can demand that they switch to green energy.

Or better yet, integrate those processes into your own renewable grid.

Use A Framework That Keeps You On Track

Technology is great. But without a framework to tie everything together, it’s just another gadget on the pile.

This is where CarbonMinus comes in. Our tools are built to do more than just monitor or optimize. They create a continuous improvement system where every piece of your operation is accounted for, analyzed, and improved on a loop.

Here’s how it works:

- Real-Time Monitoring: Track water use in real-time. Know exactly where your energy is going.

- Predictive Maintenance: Anticipate breakdowns before they happen. Fix problems before they cost you.

- Process Optimization: Keep refining your systems. The goal isn’t just efficiency—it’s continuous improvement.

- Renewable Integration: Use green energy where it counts the most. Turn Scope 3 emissions into zero-emissions.

The best part? Every improvement is measurable. You’re not guessing anymore but proving the reductions.

To know more, you can reach us at https://carbonminus.com/contact-us/

Industry-Specific Strategies

Every industry burns water differently. Here’s how you can start cutting down emissions based on your sector:

- Steel: Install predictive maintenance systems for cooling towers and chillers. These processes are energy hogs when they fall out of calibration.

- Chemicals: Optimize heating and cooling systems used in chemical reactions. That’s where most of your energy loss is hiding.

- Textiles: Target water heating and wastewater treatment. Upgrade outdated boilers and integrate AI to manage flow rates and temperatures.

- Food & Beverage: Monitor and optimize every stage of water use from washing and rinsing to boiling and cooling. And power everything you can with renewables.

Whatever your industry, the strategy is the same: Stop treating Scope 3 emissions like an afterthought.

Start tracking, predicting, and optimizing. And use renewables wherever you can.

You’re either leading the pack or trying to catch up. And the difference comes down to how fast you’re willing to make water work for you, not against you.

You’re Closer to a Solution Than You Think

You’ve been running your operation like everyone else, fixating on Scope 1 and Scope 2 because that’s where the spotlight shines.

Meanwhile, water-related emissions have been lurking in the background, hiding under Scope 3 like a broken pipeline beneath your factory floor.

Now you know better.

You can’t afford to ignore the carbon trail tied to water use. Not when every cubic meter generates over 10 kgs of CO₂.

Not when water-related processes account for roughly 13% of U.S. electricity consumption. That’s a staggering amount of carbon left untracked.

But here’s the thing: You’re not as far off as you think. The tools you need are already within reach. The strategy is clear:

- Track water-related emissions in real-time.

- Use predictive maintenance to eliminate inefficiencies before they cause damage.

- Optimize your processes relentlessly.

- Power everything you can with renewables.

You don’t need to overhaul your entire operation overnight. Just start with the leaks you’ve been ignoring. The pieces are already there.

All you have to do is connect them.

The ones who figure this out now? They’ll own the future.

Everyone else will spend their time playing catch-up.

The choice is yours.

Know more at https://carbonminus.com/contact-us/

FAQs

Q: Why do Scope 3 water emissions matter if they’re indirect?

Because indirect doesn’t mean optional. Scope 3 is where most emissions—and risk—hide. Regulators and investors are already shifting their focus here.

Q: How do I convince leadership to invest in water emissions tracking?

Use ROI. Show how much energy water systems consume. Quantify the savings from predictive maintenance and efficiency upgrades. Then tie it to compliance and reputation risk.

Q: Are there industry benchmarks for water-related emissions?

Not yet across the board—but CarbonMinus helps establish internal benchmarks, track improvements, and align with ISO50001, ISO14064, and BRSR frameworks.

Q: What if my water systems are outsourced?

You can still demand data. Push vendors to report emissions and switch to renewables. Or better—bring systems in-house and monitor them directly.

Q: How long does it take to see impact after tracking begins?

With real-time monitoring and predictive analytics, impact is visible within weeks—especially in energy-intensive operations with outdated equipment.