Key Takeaways

- The Unified Problem: Industry 4.0 reveals that energy waste and equipment downtime are not separate issues, but two symptoms of the same core problem: a lack of operational intelligence.

- Uptime Drives Efficiency: The pursuit of 99.99% uptime through AI-powered predictive maintenance in manufacturing directly causes a 15-20% reduction in energy consumption, as the most reliable machines are also the most efficient.

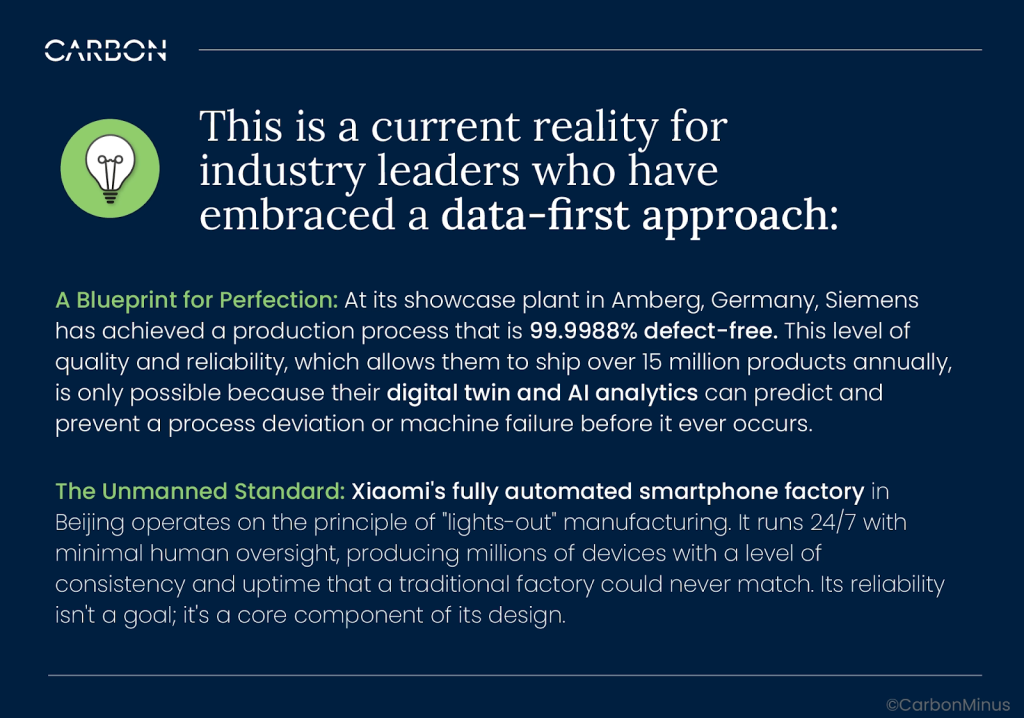

- Proven, Not Theoretical: This is not future tech. Global leaders like Siemens and Xiaomi are already achieving near-perfect uptime and quality rates by leveraging digital twins and AI-driven automation.

- Rapid & Compounding ROI: The financial returns are significant and fast. Studies show leaders achieving up to 184% ROI within three years from a combination of reduced downtime, lower maintenance costs, and energy savings.

- A Phased, Achievable Roadmap: Successful transformation is not a single leap but a three-phase journey: 1) Build a data foundation, 2) Activate AI intelligence, and 3) Scale to enterprise dominance.

For the past decade, manufacturing leaders have been told a simple story: embrace Industry 4.0 to get “smarter.” But “smarter” has remained a vague, often unquantifiable promise.

It has left executives wrestling with two very real, very expensive problems that refuse to disappear: the relentless rise of energy costs and the catastrophic impact of unplanned downtime.

Factories have treated these as separate wars. The energy team chases percentage points off utility bills through annual audits and bulk purchasing agreements. The maintenance team, armed with wrenches and spreadsheets, heroically fights the daily fires of equipment failure.

Each operates in its own silo, winning small battles while the war for profitability is steadily lost.

This is a critically outdated approach.

The true impact of Industry 4.0 and energy-efficiency in industrial plants

More than connecting machines, it’s about connecting problems. Industry 4.0 reveals that energy waste and equipment failure are symptoms of the same disease: a fundamental lack of operational intelligence.

The subtle energy fluctuations that signal an overworked motor are the same tremors that precede a catastrophic bearing failure. The inefficiencies that inflate your energy bill are the same ones that stress your equipment to its breaking point.

This guide is not another abstract report on the “factory of the future.” It is a strategic analysis for the leaders of today, providing a data-driven case that the single most powerful way to slash energy consumption is by relentlessly pursuing uptime.

We will demonstrate, with verified market data and real-world examples, how AI-powered predictive analytics are delivering a 20% reduction in energy use as a direct consequence of achieving near-perfect 99.99% equipment availability.

This is the new paradigm. Stop fighting two separate wars. It’s time to win the single battle for intelligence that solves both problems at once.

The New Math of Predictive Maintenance in Manufacturing: Deconstructing the 99.99% Uptime Promise

For decades, the pursuit of uptime has been a game of inches, where an improvement from 95% to 97% was considered a massive victory. The figure “99.99%” seemed like a theoretical limit, a marketing gimmick reserved for mission-critical data centers, not the messy reality of a factory floor.

Let’s translate what this number actually means. A factory running at 95% uptime loses 438 hours of production to unplanned downtime each year. At 98%, that number is still 175 hours.

At 99.99% uptime, you lose just 52 minutes.

This is a complete transformation of what is possible. This is the mathematical proof of the shift from reactive to predictive operations. It’s a world where you are no longer surprised by failure.

How is this possible? The answer is predictive maintenance in manufacturing

AI-powered predictive maintenance in manufacturing has fundamentally changed the equation. By analyzing thousands of operational variables like vibration, temperature, power consumption, and acoustics AI models can identify the faint signals of impending failure weeks or even months in advance.

The result is a proven 35-45% reduction in unplanned downtime and a 25-30% cut in maintenance costs.

These examples are not meant to be intimidating. They are meant to be a blueprint. They demonstrate that when you shift your focus from fixing breakdowns to reliability-centered maintenance, you redefine the operational and financial limits of your entire business.

The relation between energy waste and reliability-centered maintenance

For years, a Chief Financial Officer saw two separate, frustrating line items: the money spent on maintenance to keep machines running, and the money spent on energy to power them.

The common wisdom was that these were opposing forces. To increase output (and thus energy consumption), you often had to push machines harder, risking reliability.

Industry 4.0 intelligence reveals this assumption to be fundamentally flawed. In fact, the exact opposite is true. Energy waste is the earliest, most reliable symptom of poor equipment health and process inefficiency. A machine that is wasting energy is a machine that is on the path to failure.

This symbiotic relationship is visible across the entire factory floor:

- The Language of Motors: A healthy motor running a stable process has a consistent, predictable energy signature. When a bearing begins to wear, or lubrication fails, the motor must draw more power and generate more heat to overcome the increased friction. Energy anomaly detection or a spike in energy consumption is a loud, clear signal of an impending failure that an AI can detect weeks before the human ear detects a change in sound. By flagging the energy anomaly for proactive maintenance, you not only prevent a costly breakdown, but you also eliminate the weeks of wasted energy the struggling motor was consuming.

- The Cost of Process Deviations: Consider a furnace that must maintain a precise temperature. A faulty sensor or a degrading heating element can cause temperature fluctuations that lead to off-spec products. This is not just a quality control issue; it represents a massive energy waste. All the kilowatts consumed to heat that furnace and process that material are thrown away with the rejected batch. An AI that monitors and maintains perfect process integrity is, by definition, an AI that eliminates this form of energy waste.

- The Inefficiency of Stop-and-Start: Unplanned downtime is an energy consumption nightmare. The process of shutting down and restarting a complex production line is one of the most energy-intensive events in a factory’s daily cycle. Each startup draws a massive inrush of current, putting immense strain on both the grid and the equipment. By reducing unplanned downtime by 35-45%, predictive maintenance in manufacturing directly attacks and minimizes these high-cost, high-waste events.

This is why factories implementing AI-driven reliability strategies are seeing a corresponding 15-20% reduction in their overall energy consumption. The energy savings are not the result of a separate, parallel initiative. They are the direct, inevitable, and profitable consequence of running a healthier, more reliable, and more intelligent operation.

You are buying unparalleled efficiency with more uptime.

Uptime and Energy Efficiency with Industry 4.0

The transition to an AI-driven operation is not a single, terrifying leap. It is a strategic, three-phase journey that minimizes risk, proves value at every stage, and builds a foundation for lasting competitive advantage. This is the blueprint successful manufacturers are using to navigate their transformation.

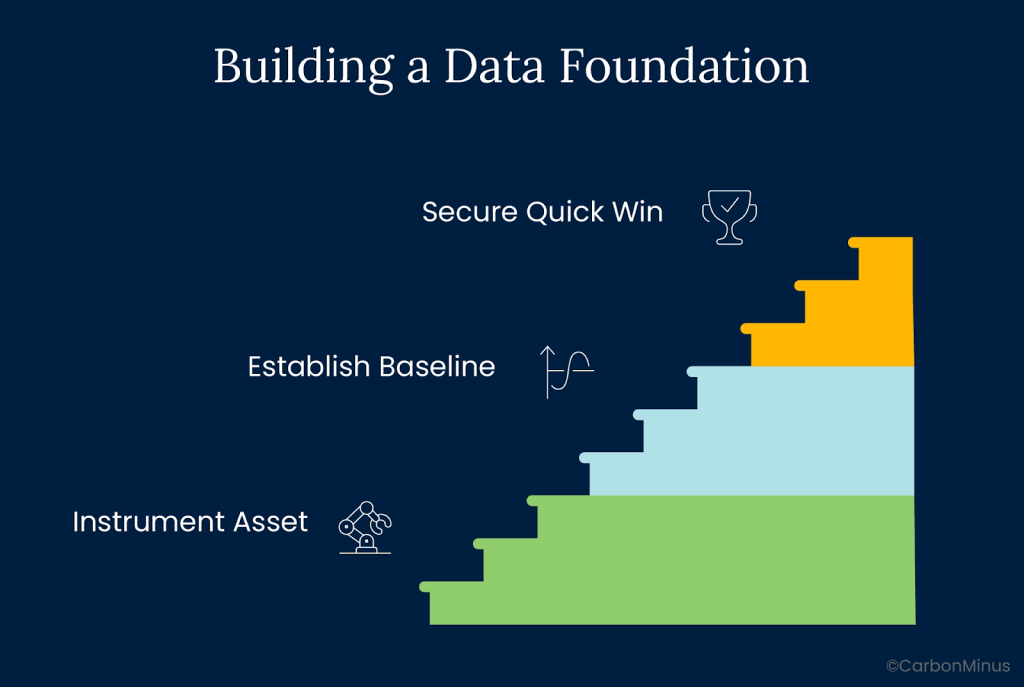

Phase 1: Build Your Data Foundation (The “Prove It” Stage)

The first and most critical phase is about making your factory “data-rich.” You cannot manage what you cannot measure.

- The Goal: To establish a single source of truth for your operational and energy data and to secure a quick, undeniable win that builds momentum for the entire program.

- Key Actions:

- Instrument a Critical Asset: Select one high-value, problem-prone production line. Deploy IoT sensors to capture key variables—energy consumption, vibration, temperature, and output.

- Establish a Baseline: Collect data for several weeks to create a detailed, undeniable baseline of its current performance, including its true energy cost and its pattern of minor stops and full breakdowns.

- Secure the Quick Win: By simply visualizing this new data, your team will immediately spot low-hanging fruit—inefficient startup procedures, energy spikes during idle times, or abnormal vibrations. Addressing these will deliver a quick, measurable improvement (e.g., a 5-10% reduction in downtime on that specific asset) that proves the value of data to even the most skeptical CFO.

Phase 2: Activate Intelligence with Energy Anomaly Detection (The “Predict and Optimize” Stage)

With a proven data foundation, you can now layer on the intelligence that drives transformative results.

- The Goal: To shift from reacting to problems to proactively preventing them, and to begin optimizing your processes based on AI-driven insights.

- Key Actions:

- Deploy the AI Platform: Integrate an AI-powered platform like CarbonMinus. The platform will ingest the data from your pilot asset and begin learning its unique operational signature.

- Enable Predictive Alerts: The AI will quickly start identifying patterns that precede failure. Your reliability-centered maintenance team will shift from a time-based schedule to a condition-based one, acting on alerts like, “Motor on Line 3 shows a 70% probability of bearing failure within 14 days.” This is where you’ll see downtime plummet by 35-45%.

- Begin Energy Anomaly Detection: The same AI will identify energy waste patterns. It will flag machines that are drawing too much power for their current workload, allowing you to optimize settings and achieve a 15-20% reduction in energy use on that line.’

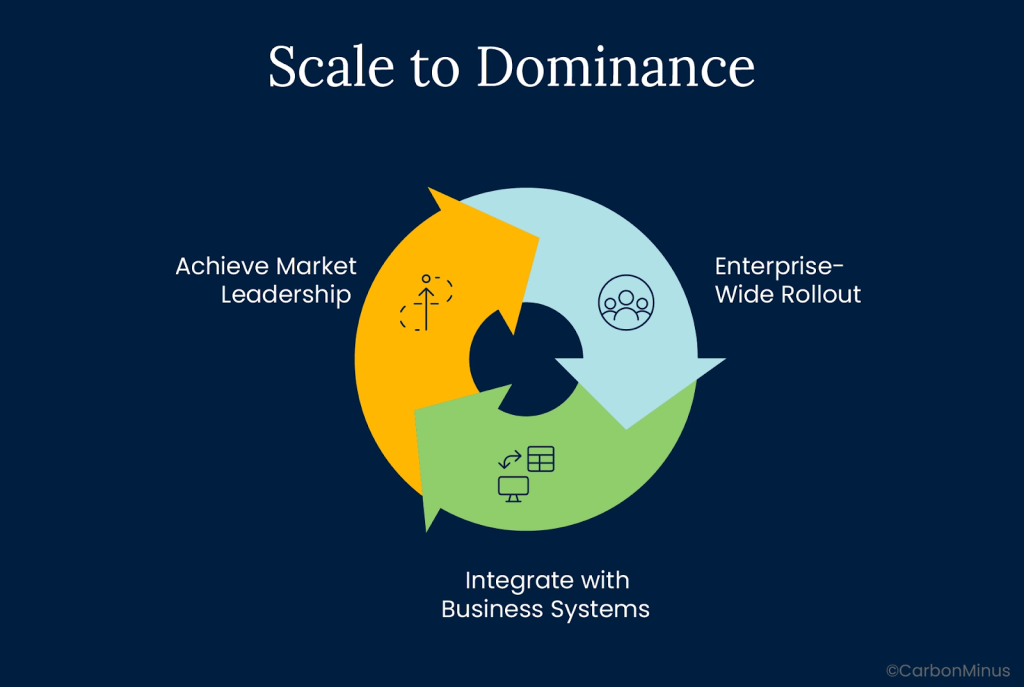

Phase 3: Scale to Dominance (The “Automate and Lead” Stage)

With a proven model, a clear ROI, and a trained team, you are now ready to scale this intelligence across your entire operation.

- The Goal: To embed data-driven intelligence into the DNA of your entire manufacturing process, creating an automated, self-optimizing system.

- Key Actions:

- Enterprise-Wide Rollout: Expand the sensor and AI platform deployment across all critical assets and facilities.

- Integrate with Business Systems: Connect the AI platform’s insights into your existing ERP and SCADA systems. This allows for automated adjustments to production schedules based on maintenance needs and real-time energy pricing.

- Achieve Market Leadership: At this stage, your factory is no longer just a place that makes products. It is a highly efficient, predictable, and resilient system. The massive savings from near-zero downtime and optimized energy use can be reinvested into innovation, more aggressive pricing, and faster growth, cementing your position as a market leader.

Seizing the Competitive Edge in Industrial Manufacturing

The path to Industry 4.0 is paved with both immense opportunity and legitimate concerns. Acknowledging and addressing the tough questions head-on is the mark of a sound strategy.

Objection #1: The ROI is not proven and the payback is too long

This is the most common myth, and the data proves it false. This isn’t a speculative, decade-long bet. Real-world implementations show a clear and rapid return. A comprehensive study of smart factory initiatives revealed that leaders are achieving as high as 184% ROI within three years. The savings are not theoretical; they are the direct result of slashing downtime, eliminating energy waste, and boosting output.

Objection #2: This is too complex. My existing systems can’t handle it, and my team doesn’t have the skills

This concern is valid, which is why a “rip and replace” strategy is the wrong approach. The right strategy, and the one embedded in platforms like CarbonMinus, is built on seamless integration and empowerment.

- On Technology: Modern Industry 4.0 solutions are designed for “brownfield” environments. They use intelligent gateways and IoT sensors to pull data from your existing legacy equipment, layering AI intelligence on top of your current infrastructure without requiring a disruptive overhaul.

- On People: The goal of a well-designed AI platform is not to replace your team, but to augment their expertise. It translates billions of data points into simple, actionable alerts through energy anomaly detection (e.g., Motor on Line 3 is under/overperforming, showing a 70% probability of bearing failure within 14 days). This empowers your existing reliability-centered maintenance and operations staff to make smarter, data-driven decisions, transforming them into proactive problem-solvers.

The Cost of Inaction is Your Biggest Risk

The global market for smart manufacturing is not just growing; it’s creating a new class of hyper-efficient leaders. We are already seeing AI-native startups achieve $100 million in revenue with teams as small as 45 people.

That’s a level of productivity that is mathematically impossible for a traditional, reactive manufacturer to compete with.

Every day you wait, the gap widens. Your competitors who are adopting these tools now are not just cutting costs; they are creating a formidable, data-driven moat around their business. They are using their savings from eliminating downtime and reduced energy consumption to fund innovation, lower their prices, and capture market share.

The choice is stark. You can continue to fight a losing, two-front war against energy costs and downtime, or you can embrace the single solution that conquers both.

This is no longer a question of if, but when. And when it comes to securing a dominant position in your market, “when” is always “now.”

Ready to turn your operational data from a missed opportunity into your greatest competitive asset?

Sign up with CarbonMinus today and take the first, decisive step into the future of manufacturing.

FAQs

What kind of energy savings can AI really achieve in a factory?

By using AI for real-time process optimization and predictive maintenance in manufacturing, factories are consistently achieving 15-20% reductions in their overall energy consumption. This is accomplished by eliminating waste from inefficient machine performance and avoiding energy-intensive shutdowns and restarts.

Is 99.99% uptime a realistic goal for a typical manufacturing plant?

While 99.99% (just 52 minutes of downtime per year) is the gold standard, it is becoming increasingly achievable for factories that fully embrace AI-driven predictive maintenance in manufacturing. More importantly, the journey toward that goal delivers massive value, with typical downtime reductions of 35-45%.

How can I implement this AI technology with my older, legacy equipment?

This is a key challenge that modern Industry 4.0 platforms are built to solve. Through “brownfield” deployment, IoT sensors and intelligent gateways are used to extract data from your existing machinery, allowing you to layer on AI intelligence without needing to rip and replace your current systems.

What is the real ROI on an Industry 4.0 project like this?

The ROI is multifaceted and rapid. Studies have shown leading manufacturers achieving as high as 184% ROI within three years. This return is driven by a combination of direct energy cost savings, drastically reduced reliability-centered maintenance expenses, and the significant revenue gains from increased production capacity and uptime.

Will I need to hire a team of data scientists to run this?

No. The goal of a modern AI platform like CarbonMinus is to democratize data science. It translates billions of complex data points into simple, actionable alerts and recommendations for your existing operations and maintenance teams, empowering them to make smarter decisions without needing a Ph.D. in statistics.

References

Core Concepts: Industry 4.0, AI, and Energy Efficiency

- CarbonMinus – How IoT and AI Revolutionize Energy Management: https://carbonminus.com/how-iot-and-ai-revolutionize-energy-management/

- CarbonMinus – AI vs. Carbon Emissions: A Sustainability Revolution: https://carbonminus.com/ai-vs-carbon-emissions-a-sustainability-revolution/

- NextGenInvent – Optimize Energy Consumption in Manufacturing Industries Using AI: https://nextgeninvent.com/blogs/ai-reducing-energy-consumption-in-manufacturing/

- RACE for 2030 – Industry 4.0 for energy productivity: https://www.racefor2030.com.au/project/b2-industry-4-0-for-energy-productivity/

- SAP – Industry 4.0: The Future of Manufacturing: https://www.sap.com/india/products/scm/industry-4-0/what-is-industry-4-0.html

Uptime and Predictive Maintenance

- CarbonMinus – Why Smart Factories Switch to Predictive Maintenance in 2025: https://carbonminus.com/why-smart-factories-switch-to-predictive-maintenance-in-2025/

- CarbonMinus – AI-Powered Predictive Maintenance: https://carbonminus.com/ai-powered-predictive-maintenance-for-sustainability-efficiency/

- Binary Semantics – Predictive Analytics and Its Impact on the Manufacturing Industry: https://www.binarysemantics.com/blogs/predictive-analytics-and-its-impact-on-the-manufacturing-industry/

- Okta – 99.99% Uptime For Every Customer: https://www.okta.com/blog/2020/07/99-point-99-percent-uptime-for-all/

- UptimeAI – Case Studies Archives: https://www.uptimeai.com/resources/category/case-studies/

ROI, Business Impact, and Market Trends

- SL Controls – Benefits of Industry 4.0: https://slcontrols.com/benefits-of-industry-4-0/

- HighGear – Industry 4.0 Benefits for Manufacturers: https://www.highgear.com/blog/benefits-of-industry-4-0/

- Startus Insights – Future of Manufacturing Trends: https://www.startus-insights.com/innovators-guide/future-of-manufacturing/

- FactoryEye – Can you improve ROI using Industry 4.0?: https://factoryeye.magicsoftware.com/blog/roi-check-in-can-you-improve-roi-using-industry-4-0/

- Datalumina – Exploring how small teams build $100M+ AI companies: https://www.datalumina.com/insights/insight/exploring-how-small-teams-build-usd100m-ai-companies

Implementation Challenges and Solutions

- insightsoftware – Common Predictive Analytics Challenges & Solutions: https://insightsoftware.com/blog/the-4-common-challenges-of-predictive-analytics-solutions/

- Hexagon – Addressing current issues in predictive analytics: https://aliresources.hexagon.com/operations-maintenance/addressing-current-issues-in-predictive-analytics

- VirtusLab – What is Industry 4.0: benefits and challenges: https://virtuslab.com/blog/business-insights/industry-4-0-benefits-and-challenges/