TL;DR

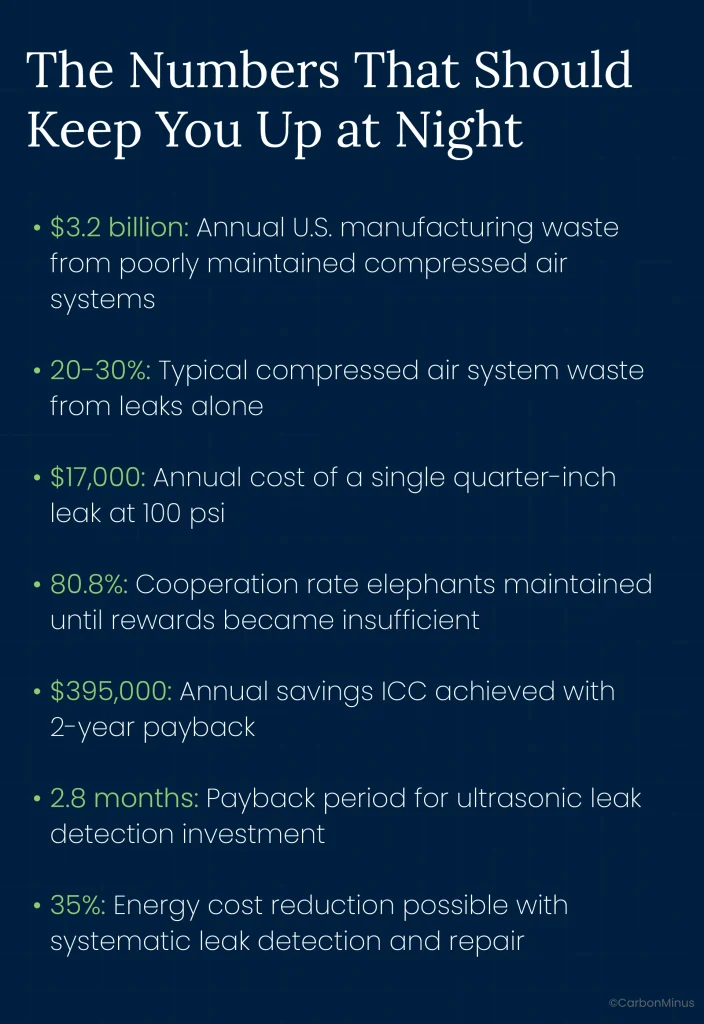

- A single quarter-inch compressed air leak costs foundries $17,000 annually, yet most facilities lose 20-30% of their compressor output to preventable leaks.

- When Indianapolis Casting Corporation’s compressed air system collapsed from internal dysfunction, maintenance couldn’t fix leaks fast enough.

- They implemented ultrasonic leak detection, stabilizing system pressure, and cross-functional accountability.

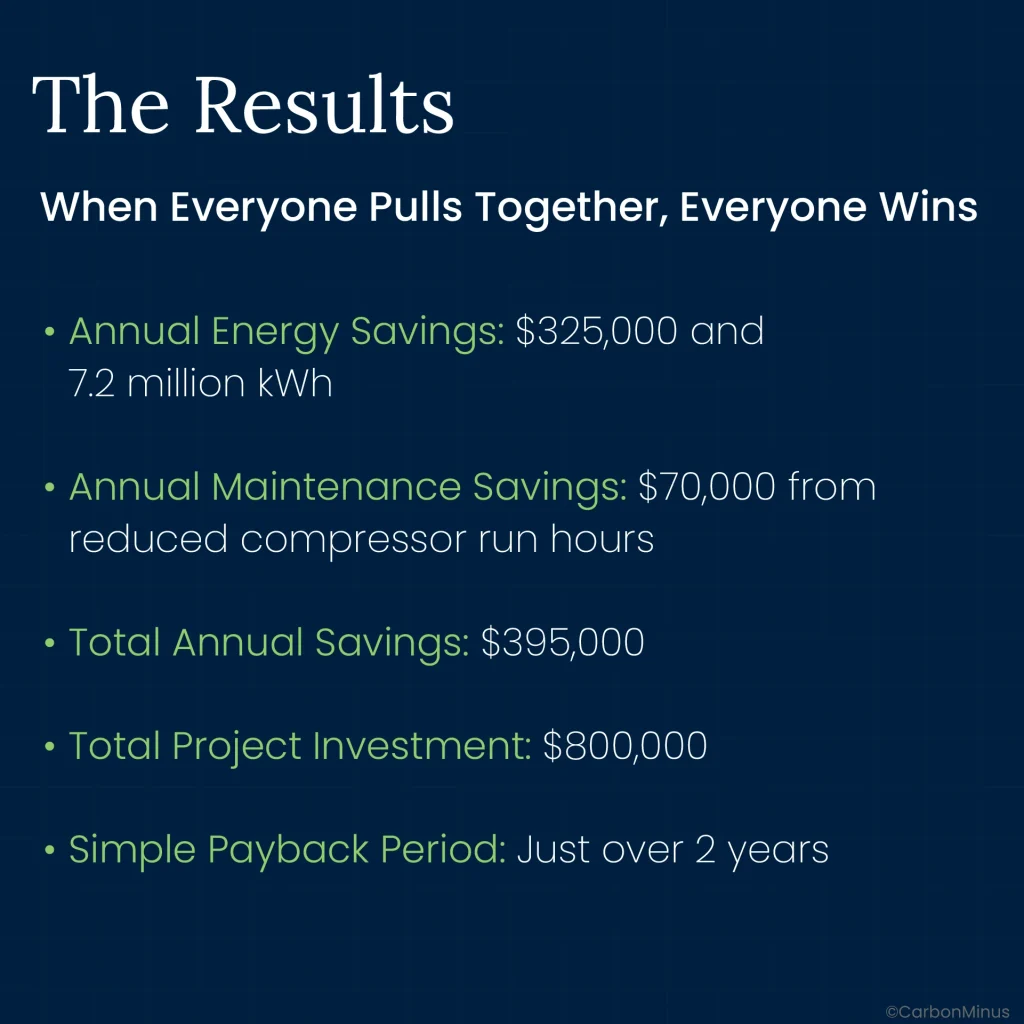

- They eliminated 7.2 million kWh in waste and saved $395,000 annually with a 2-year payback on their $800,000 investment.

- The breakthrough was getting departments to cooperate around shared data instead of competing priorities.

In 2021, researchers at Thailand’s Elephant Conservation Center handed pairs of Asian elephants an ingenious challenge: pull both ends of a rope simultaneously to drag a platform loaded with food toward them. The elephants crushed it, maintaining an impressive 80.8% cooperation rate across 45 sessions.

But here’s where it gets interesting for foundry managers.

The researchers introduced competition—placing food where only one elephant could easily access it. Initially, cooperation held strong. The elephants deployed sophisticated strategies: blocking, fighting back, leaving, moving aside, and submission. They balanced self-interest with teamwork beautifully.

Until the rewards became insufficient. Then cooperation didn’t decline gradually, it collapsed completely.

Sound familiar?

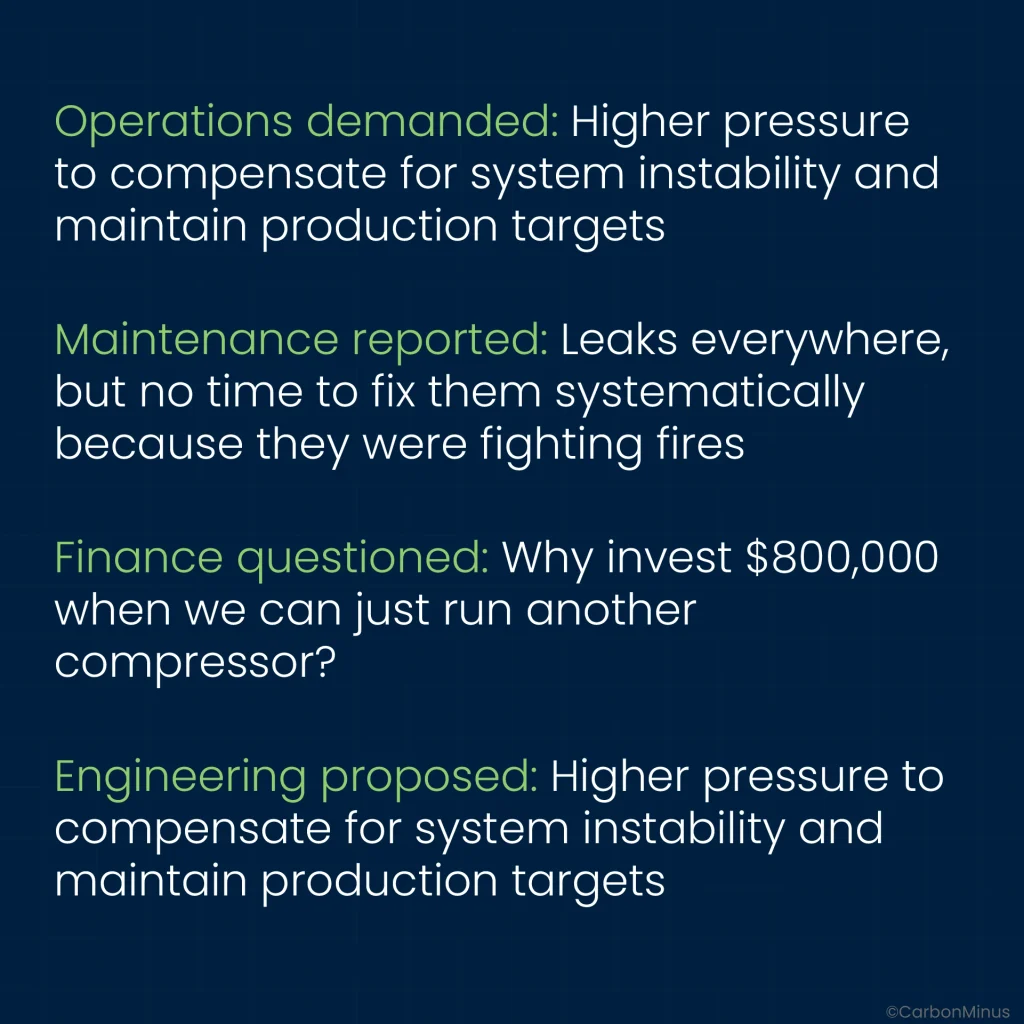

That’s exactly what happens in your compressed air system every single day. Maintenance knows about the leaks but can’t get budget approval.

Operations cranks up pressure to compensate for losses instead of fixing the root cause.

Finance questions every repair because they can’t see the invisible waste.

Engineering proposes solutions that get shelved for “more urgent” priorities.

Everyone’s pulling their own rope. Nobody’s getting fed.

And while your departments fight over priorities, a single quarter-inch leak is draining $17,000 annually from your bottom line. Multiply that by dozens of leaks scattered across your facility, and you’re looking at $200,000 to $500,000 in annual waste that nobody owns.

The Invisible Money Drain That’s Bankrupting Your Margins

Here’s a number that should make every foundry manager’s stomach turn: 20-30% of your total compressor output is escaping through leaks right now.

Not someday. Not in underperforming facilities. Right now. In your plant.

The Compressed Air & Gas Institute puts it bluntly: improperly maintained compressed air systems waste $3.2 billion annually across U.S. manufacturing. That’s not a typo. Billions with a “B.”

Let’s make this concrete:

The Cost of Doing Nothing.

- A 1/8-inch leak (pinhole-sized): $3,900/year

- A 1/4-inch leak (quarter-sized): $17,000/year

- System-wide 20-30% waste: $200,000-$500,000/year for typical foundries

That constant hissing sound in your facility? That’s the sound of profit evaporating into thin air while everyone walks past it daily without seeing it.

For every $1,000 you spend on electricity, $510 vanishes into thin air before it does any productive work. Compressed air leaks are the single largest contributor to this silent theft.

Most facilities treat compressed air like it’s free. It’s not. Every leak is cash flowing directly out of your facility, cash that could be funding equipment upgrades, employee bonuses, or competitive pricing advantages.

When Your Departments Stop Talking, Your Compressors Keep Running

Indianapolis Casting Corporation (ICC), a 500-employee foundry producing engine blocks for International Truck and Engine Corporation faced a compressed air crisis that perfectly mirrored the elephant cooperation study.

The dysfunction was organizational, not technical.

The result? ICC was running excess compressor capacity while still experiencing production interruptions. They were spending massive energy dollars, maintenance teams were overwhelmed, and production still suffered from pressure fluctuations.

Sound familiar? That’s the compressed air paradox: more capacity, worse performance, higher costs.

It’s the industrial equivalent of elephants pulling separate ropes while the food stays out of reach.

What Actually Worked: The $395K Turnaround Story

In the late 1990s, ICC implemented something radical: they made all departments pull the same rope.

Here’s what changed.

They Made the Invisible Visible

Ultrasonic leak detection revealed the scope of waste that everyone knew existed but nobody could quantify. Suddenly, maintenance had hard data, finance had ROI projections, and operations had a path to stable pressure.

The technology detects high-frequency sounds produced by air leaks—sounds inaudible to human ears but devastating to energy budgets. Implementation happens within days, not months.

Ultrasonic leak detection provides precise, non-destructive assessment supporting cost savings and operational excellence. Facilities implementing this technology reduce energy costs by up to 35%.

They Stabilized Pressure Instead of Cranking It Higher

Rather than operating compressors at elevated discharge pressure to compensate for losses, ICC lowered and stabilized system pressure to the minimum practical level. This reduced air consumption, leak rates, and overall energy demand.

Operating at unnecessarily high pressure is like driving with one foot on the accelerator and one on the brake—expensive and destructive.

They Fixed Leaks Systematically, Not Reactively

Armed with data and cross-functional buy-in, maintenance repaired leaks systematically, starting with the largest drains. They identified misapplied end uses (applications that shouldn’t use compressed air at all) and eliminated artificial demand.

They Installed Adequate Storage and Controls

ICC added two 12,500 scfm-rated dryers and proper receiver tank capacity to handle demand fluctuations without pressure swings. Automatic sequencing brought compressors online only when needed, eliminating the “panic mode” operations that killed efficiency.

Proper storage allows systems to anticipate peak demands without running excess compressor capacity continuously.

They Eliminated Moisture and Contaminants

Severe moisture and lubricant carryover was causing production quality issues and equipment failures. Improved air treatment delivered drier, cleaner air that reduced scrap rates and extended equipment lifespan.

But the financial returns tell only half the story. ICC also achieved:

Stable, consistent air pressure that eliminated production interruptions

Improved product quality with reduced scrap rates from cleaner, drier air

Increased production capacity by eliminating downtime from pressure fluctuations

Enhanced system reliability that allowed predictive maintenance instead of emergency repairs

The breakthrough wasn’t buying better equipment. It was getting departments to cooperate around shared data instead of competing priorities.

Converting to and maintaining a well-designed, stable, and uncontaminated supply of air is important for compressed air systems to operate efficiently. It leads to energy savings, improved production, and competitive advantage.

The Cooperation Framework: Making Optimization Stick

The elephant study revealed something profound: cooperation thrives when all parties see clear, consistent rewards. The moment rewards become uncertain or unevenly distributed, cooperation collapses rapidly.

ICC’s success came from creating a framework where every department saw tangible, immediate benefits.

For Operations

- Stable pressure eliminated production interruptions

- Predictable system performance improved throughput

- Reduced scrap rates from cleaner air quality

For Maintenance

- Lower compressor run hours reduced emergency repairs

- Systematic leak detection replaced firefighting mode

- Predictive maintenance became possible with stable baselines

For Finance

- $395,000 annual savings with 2-year payback

- Reduced power demand lowered utility costs

- Quantifiable ROI justified continued optimization investment

For Engineering

- Real-time monitoring data enabled continuous improvement

- System reliability metrics validated design changes

- Documented success secured budget for future projects

When everyone pulls the same rope toward visible, shared rewards, cooperation compounds.

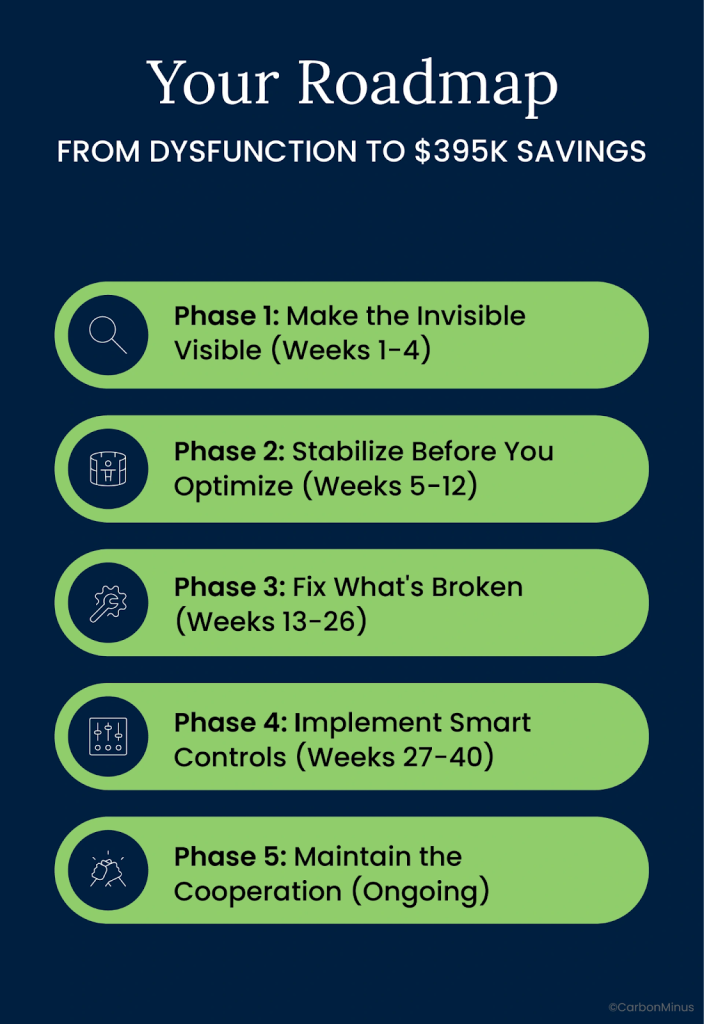

Your Roadmap: From Dysfunction to $395K Savings

Based on ICC’s documented success and industry best practices, here’s your implementation framework:

Phase 1: Make the Invisible Visible (Weeks 1-4)

Conduct ultrasonic leak detection survey across your entire facility. Document leak locations, sizes, and estimated annual costs. This creates the shared data foundation that makes cooperation possible.

Expected investment: $15,000-$40,000 for detection equipment and training

Expected ROI: 2.8 months for detection investment alone

Phase 2: Stabilize Before You Optimize (Weeks 5-12)

Measure current system pressure profile at multiple points to identify pressure drops and unstable zones. Target the lowest practical operating pressure for your applications—every 2 psi reduction saves 1% in energy consumption.

Install or upgrade receiver tank capacity to handle demand fluctuations without pressure swings. Central receivers regulate compressor load/unload cycles; local receivers at high-demand areas prevent sudden pressure drops.

Phase 3: Fix What’s Broken (Weeks 13-26)

Repair leaks systematically, starting with the largest. Target reducing leak rates from typical 20-30% to less than 10%.

Eliminate misapplied end uses: applications inappropriately using compressed air when alternatives exist. Challenge every point-of-use requirement.

Upgrade air treatment systems (dryers, filters) to deliver appropriate air quality without over-treating.

Phase 4: Implement Smart Controls (Weeks 27-40)

Deploy automatic sequencing controls so only the number of compressors required to meet real-time demand are operating. Only one compressor should run in “trim” mode.

Install real-time monitoring systems that track pressure, flow, power consumption, and leak rates continuously. Real-time monitoring delivers 4x better results than traditional annual audits, achieving 20% savings vs. 5% from conventional approaches.

Phase 5: Maintain the Cooperation (Ongoing)

Create cross-functional energy teams with representatives from operations, maintenance, finance, and engineering. Establish shared KPIs that align departmental incentives.

Implement quarterly leak detection audits to prevent regression. New leaks develop continuously, vigilance is the price of sustained savings.

Track and communicate wins across all departments to maintain buy-in and justify continued optimization investment.

When Cooperation Becomes Your Competitive Advantage

The elephant researchers discovered something that applies directly to your compressed air system: cooperation is strategic. Animals (and departments) cooperate when the visible rewards outweigh the effort and uncertainty.

ICC succeeded because they made cooperation the path of least resistance:

They eliminated uncertainty with real-time data everyone trusted

They aligned incentives so every department benefited from optimization

They delivered quick wins that proved the strategy before asking for bigger investments

They maintained visibility into results so cooperation didn’t collapse when priorities shifted

Your compressed air system isn’t failing because of bad equipment. It’s failing because your departments are pulling separate ropes.

The technology to fix it: ultrasonic detection, smart controls, proper storage, optimized pressure already exists and pays for itself in months, not years. The hard part isn’t technical. The hard part is getting everyone to pull together.

But when you do, you don’t just save $395,000 annually. You create a competitive advantage that’s invisible to competitors and impossible to replicate without the same organizational cooperation.

That constant hissing sound? It’s not just air escaping. It’s your competition pulling together while your departments pull apart.

The only question left is: Are you ready to make everyone pull the same rope?

How CarbonMinus Helps Foundries Eliminate Compressed Air Waste

CarbonMinus provides real-time energy monitoring and optimization platforms specifically designed for heavy industries like foundries. Our system makes compressed air waste visible, quantifiable, and actionable, creating the data foundation that drives cross-functional cooperation.

Real-time leak detection and quantification: See exactly where you’re losing money, 24/7

Automated alerts and prioritization: Focus maintenance efforts on the highest-impact repairs first

ROI tracking and reporting: Justify optimization investments with clear, department-specific benefits

Cross-functional dashboards: Align operations, maintenance, finance, and engineering around shared data

To learn more about reducing compressed air costs through real-time energy visibility, visit carbonminus.com

or calculate your potential savings at roi.carbonminus.com

FAQs

How much does a compressed air leak actually cost?

A quarter-inch compressed air leak operating continuously at 100 psi costs approximately $17,000 annually in wasted electricity. Even a pinhole-sized 1/8-inch leak costs over $3,900 per year. Most foundries have dozens of these leaks scattered throughout their facilities, creating total system waste of 20-30% of compressor output, which translates to $200,000-$500,000 in annual losses for typical operations.

What ROI can we expect from compressed air optimization?

Indianapolis Casting Corporation achieved $395,000 in annual savings (energy plus maintenance) with a total investment of $800,000, yielding a simple payback of just over 2 years. Ultrasonic leak detection equipment alone delivers ROI in as little as 2.8 months for medium-sized facilities. Facilities implementing systematic leak detection and repair typically reduce energy costs by up to 35%.

How do we identify compressed air leaks in a noisy foundry environment?

Ultrasonic leak detection equipment detects the high-frequency sounds produced by compressed air leaks—sounds that are inaudible to human ears but easily identified by specialized sensors. This technology works effectively even in extremely noisy manufacturing environments where traditional auditory detection is impossible. Implementation typically takes days, not months, and provides precise leak location, size estimation, and cost quantification data.

Why do compressed air optimization projects fail?

Most compressed air optimization projects fail due to organizational dysfunction, not technical limitations. When operations, maintenance, finance, and engineering departments operate with competing priorities and limited visibility into shared costs, optimization initiatives get deprioritized despite clear ROI. Successful projects create cross-functional cooperation by providing real-time data that makes invisible waste visible and aligns departmental incentives around measurable, shared benefits.

What’s the fastest way to reduce compressed air costs?

The fastest path to compressed air savings combines three actions: (1) Conduct ultrasonic leak detection to quantify waste and prioritize repairs (2.8-month payback); (2) Repair the largest leaks first to achieve immediate 10-20% reduction in system waste; and (3) Lower system operating pressure to the minimum practical level—every 2 psi reduction saves 1% in energy consumption. These interventions require minimal capital investment and deliver results within weeks.

How does compressed air waste impact production quality?

Unstable compressed air pressure causes production interruptions, inconsistent process performance, and increased scrap rates. When ICC stabilized their system pressure and improved air treatment to eliminate moisture and lubricant carryover, they achieved not only $395,000 in annual energy and maintenance savings but also improved product quality with reduced scrap and eliminated production downtime from pressure fluctuations. Stable, clean compressed air directly impacts bottom-line profitability through both energy savings and production reliability.

What maintenance practices prevent compressed air waste from returning?

Sustainable compressed air efficiency requires quarterly ultrasonic leak detection audits since new leaks develop continuously through normal wear, vibration, and thermal cycling. Pairing these efforts with thermal energy storage solutions can further stabilize plant energy demand, reduce peak loads, and improve overall system efficiency. Implement automatic monitoring systems that track pressure, flow, and power consumption in real-time to detect degradation before it becomes catastrophic. Create cross-functional energy teams with shared KPIs that align operations, maintenance, and finance around sustained optimization rather than one-time projects.