Thirty times.

That’s how much more potent methane is as a greenhouse gas compared to carbon dioxide, according to the Environmental Defense Fund (EDF).

Oil and gas companies are facing mounting pressure to tackle methane emissions—pressure coming from regulators, environmental watchdogs, and even investors.

The urgency to reduce methane emissions has never been greater, but traditional methods of monitoring leaks and emissions are falling short.

Not only are they insufficient, but they’re also incredibly costly and inefficient, leaving producers scrambling for better solutions.

So, how can the industry move forward?

Can new technologies like IoT and AI revolutionize methane monitoring?

Advanced methane and air quality monitoring systems powered by real-time data and automation are proving to be game-changers.

With these tools, oil and gas companies can detect leaks faster, reduce emissions more effectively, and stay compliant with stringent regulations—all while cutting costs.

It’s no longer a question of if the industry needs change, but how fast it can adopt the technology to make that change happen.

The Role of IoT Sensors in Real-Time Methane Detection

Gone are the days of waiting for scheduled inspections to detect methane leaks.

With the rise of IoT sensors, oil and gas companies can now monitor methane emissions in real time, 24/7. These smart sensors are revolutionizing the industry, allowing companies to detect and respond to leaks the moment they happen, not hours or even days later.

But scalability is the real game-changer

IoT solutions can be deployed across a single well or an entire oil field, making it accessible for both large corporations and smaller producers. The data collected is invaluable, providing detailed insights into methane trends and helping companies stay ahead of methane detection requirements.

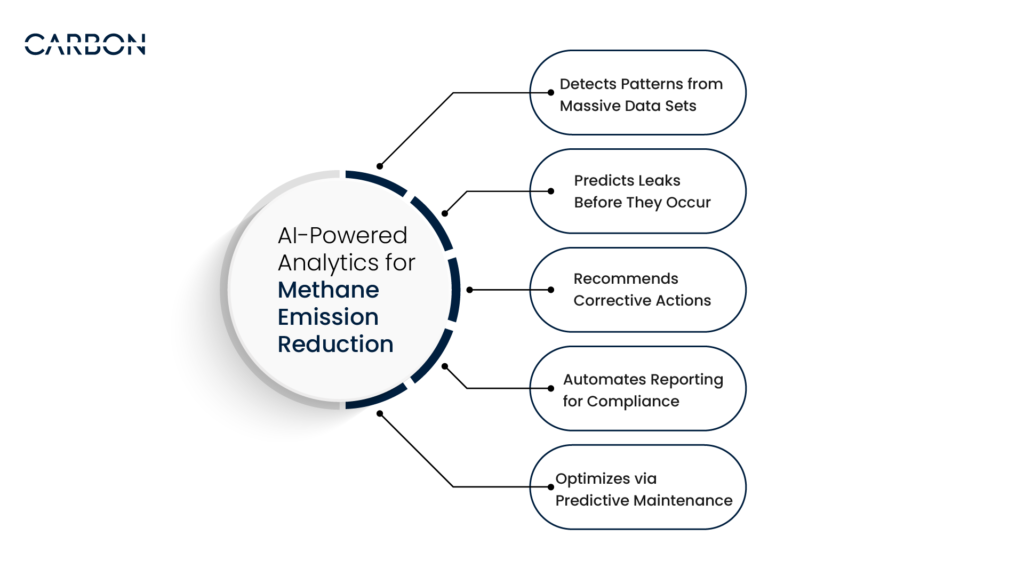

AI-Powered Analytics for Methane Emissions Reduction

What if you could prevent methane leaks before they even happen? With AI-powered analytics, oil and gas companies are now doing just that.

Here’s how AI is transforming methane emission reduction:

- Detects Patterns from Massive Data Sets: AI processes huge amounts of data from sensors, looking for patterns that might signal a potential leak. It can spot subtle shifts in pressure or temperature that often go unnoticed by human operators.

- Predicts Leaks Before They Occur: Using predictive analytics, AI identifies risk factors and trends, enabling oil producers to take action before a leak even happens. This proactive approach means fewer costly emergencies.

- Recommends Corrective Actions: Once a potential issue is detected, AI provides actionable recommendations. Whether it’s adjusting pressure or scheduling maintenance, AI’s insights can prevent leaks from ever occurring.

- Automated Compliance Management: AI also streamlines the reporting process, automatically generating real-time compliance reports that help companies stay in line with regulatory requirements.

- Optimizes Maintenance Through Predictive Maintenance: AI helps plan maintenance schedules by identifying which areas are most likely to fail, allowing companies to optimize their resources and avoid unnecessary downtime.

By predicting problems and offering real-time solutions, AI turns methane management into a proactive, cost-saving strategy.

CarbonMinus steps in as a holistic solution, designed to track, report, and manage GHG emissions across your operations. While not limited to methane, we help companies monitor their overall environmental impact, offering insights into energy use, emissions trends, and environmental compliance. By leveraging AI-powered analytics, our comprehensive picture of your operations enables companies to meet their sustainability goals efficiently. Know more at www.carbonminus.com.

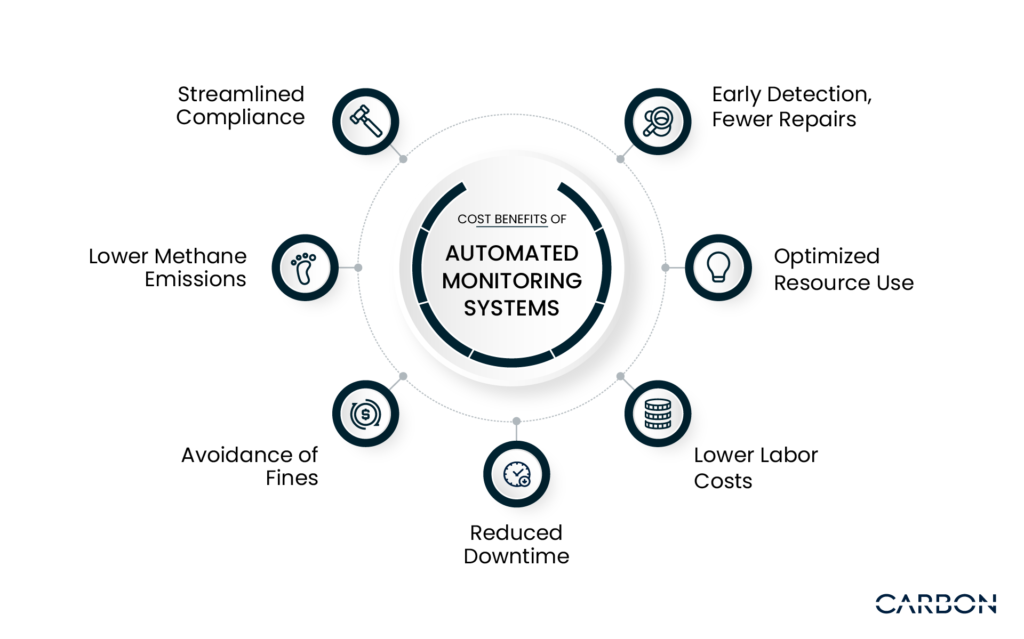

Cost Benefits of Automated Monitoring Systems

What if you could cut costs while boosting efficiency? That’s the power of automated methane monitoring systems.

These systems don’t just make detecting leaks easier—they’re designed to lower costs across the board by reducing the need for manual intervention and simplifying environmental compliance.

Here’s how:

- Lower Labor Costs: Automated systems continuously monitor methane emissions, reducing the need for frequent manual inspections, which means lower labor costs and more efficient resource allocation.

- Early Detection, Fewer Repairs: Catching leaks early means smaller issues are addressed before they escalate, saving money on large-scale repairs or equipment replacement.

- Streamlined Compliance Management: Automated systems generate real-time reports, making it easier to meet regulatory requirements without needing extensive administrative work to file manual reports.

- Avoidance of Fines: Non-compliance with methane regulations can lead to hefty fines, but with automated systems ensuring constant monitoring, companies reduce the risk of missing crucial inspections or deadlines.

- Reduced Downtime: By identifying potential issues early, automated systems help prevent equipment failure, reducing costly downtime and keeping operations running smoothly.

- Lower Methane Emissions: Early leak detection and constant monitoring ensure fewer methane emissions, aligning companies with sustainable energy goals and offering long-term savings on environmental compliance.

- Optimized Resource Use: Automation allows companies to allocate their workforce and technology investments more effectively, ensuring resources are used where they matter most.

How Energy Management Links to Methane Emissions Reduction

Energy management systems do more than monitor energy consumption—they’re a critical tool for optimizing operations and reducing emissions.

While methane emissions are often directly linked to leaks in pipelines or faulty infrastructure, there’s a deeper connection between energy efficiency and methane reduction. When companies actively manage their energy use, they can pinpoint inefficiencies that lead to excess emissions, including methane leaks.

Efficient energy management means better resource use, less waste, and fewer opportunities for methane to escape into the atmosphere.

A well-integrated energy management system gives companies the data they need to track their entire emissions profile, from greenhouse gasses (GHGs) to specific methane leaks.

By using this data to optimize processes, companies can reduce emissions across the board, ensuring compliance with stringent regulations and improving sustainability.

Future-Proofing Methane Management with Technology

Explore how CarbonMinus can help you seamlessly integrate these technologies for better GHG emission monitoring and long-term savings. Book a demo at www.carbonminus.com.

By adopting advanced tools like AI analytics and automated systems, companies can significantly reduce emissions and costs.

Frequently Asked Questions

1. How do IoT sensors help detect methane leaks in real-time?

IoT sensors are deployed across pipelines and facilities, continuously collecting data on methane levels. When a leak is detected, the sensor sends immediate alerts, enabling companies to address the issue in real-time. This constant monitoring helps reduce emissions and prevents larger operational risks by ensuring prompt responses to leaks.

2. What role does AI play in methane emission reduction?

AI analyzes vast amounts of data from methane monitoring systems to detect patterns, predict potential leaks, and recommend preventive actions. AI-driven analytics can identify subtle trends that human operators might miss, enabling predictive maintenance and optimizing methane reduction strategies by flagging high-risk areas before leaks occur.

3. How can advanced monitoring systems improve regulatory compliance?

Advanced monitoring systems automate the tracking of methane emissions, offering real-time data and automated reporting. This ensures that companies stay within regulatory limits and meet compliance deadlines, while also simplifying the reporting process, minimizing manual errors, and reducing the risk of non-compliance penalties.

4. What are the cost benefits of automated methane monitoring technologies?

Automated monitoring systems reduce the need for manual inspections, cutting labor costs and increasing efficiency. They also help companies detect leaks earlier, preventing costly repairs and fines for non-compliance. In the long run, these systems provide operational savings by ensuring that methane leaks are managed more efficiently.

5. How can predictive analytics prevent methane leaks before they happen?

Predictive analytics uses data from sensors and monitoring systems to identify patterns that suggest potential leaks. By predicting where and when a leak might occur, companies can take preventive actions—such as scheduled maintenance—before an issue arises, minimizing methane emissions and avoiding costly repairs or shutdowns.