Imagine the pipelines crisscrossing oil-rich landscapes, reminders of a world powered by fossil fuels. Today, many lie dormant—symbols of an industry grappling with change. But what if these pipelines could be transformed to carry hydrogen instead of oil, fueling a clean energy future?

The future of energy isn’t about starting from scratch. It’s about transformation. Hydrogen hubs—centralized systems connecting hydrogen production, storage, and distribution—are quietly reshaping what’s possible. These hubs turn stranded assets into opportunities, bringing us closer to a low-carbon energy future faster and more affordably than we thought possible.

So, what does it take to make this vision a reality? Let’s explore.

What Makes Hydrogen Hubs the Missing Link in Clean Energy?

Hydrogen hubs aren’t just another clean energy innovation—they’re a blueprint for how we can connect the dots in the transition to low-carbon energy.

Picture a network where renewable energy powers hydrogen production in one location, storage facilities stabilize supply, and pipelines seamlessly distribute this low-carbon fuel to industries and cities miles away.

This isn’t a far-off concept. It’s already taking shape in regions like Australia, where hydrogen hubs are bridging the gap between renewable energy resources and urban demand.

The Real Genius of Hydrogen Hubs Lies in Their Flexibility

They can integrate hydrogen from multiple sources—whether it’s green hydrogen produced from solar and wind or blue hydrogen extracted from natural gas with carbon capture. This adaptability ensures that even regions with different energy resources can adopt hydrogen as part of their decarbonization strategy.

The question isn’t whether hydrogen hubs will play a role in the future of energy—it’s how fast we can scale them to meet the growing demand for clean energy solutions.

How Old Pipelines Can Lead Us to a Cleaner Future

The thing about scaling hydrogen hubs isn’t just about ambition, but about speed. The faster we scale, the sooner hydrogen can bridge the gap between renewable energy production and industrial demand.

That said, scalability requires more than vision, it needs practical solutions that work today. That’s where existing infrastructure—pipelines, storage tanks, and refineries—offers an unexpected advantage.

Repurposing Oil and Gas Infrastructure Provides A Head Start

- Pipelines designed for natural gas, for example, can be adapted for hydrogen with relatively minor upgrades.

- Storage tanks once filled with crude oil can be re-engineered to hold hydrogen safely.

These modifications drastically reduce the time and cost required to build entirely new systems, making it easier to scale hydrogen hubs quickly.

This Approach is Already Taking Shape

In Europe, hydrogen corridors are being created by converting pipelines to connect renewable energy production in coastal regions with heavy industrial demand inland. This model demonstrates how repurposed infrastructure can accelerate the clean energy transition while maximizing existing assets.

The Economics of Scaling Hydrogen Hubs

What businesses must realise is that scaling hydrogen hubs is more than a clean energy strategy—it’s an economic win.

The Challenge and the Opportunity

The cost of building new hydrogen pipelines and storage facilities can be prohibitively high, running into billions for large-scale projects. Yet, with existing oil and gas infrastructure in place, industries have a unique opportunity to save time, money, and resources by retrofitting instead of rebuilding.

The Financial Case for Retrofitting is Compelling

Studies have shown that adapting existing natural gas pipelines for hydrogen can cost up to 80% less than constructing new hydrogen pipelines. For example, Europe’s Hydrogen Backbone initiative has identified over 40,000 kilometers of pipelines that can be repurposed, saving billions while accelerating deployment timelines.

Benefits Beyond Direct Cost Savings

By leveraging existing infrastructure, industries can reduce operational downtime and avoid the hidden costs associated with supply chain disruptions and permitting delays. Every dollar saved here can be reinvested in scaling hydrogen production, expanding distribution networks, or funding renewable energy projects.

The Long-Term Economics are Just As Promising

Hydrogen hubs create efficiencies that lower the cost per unit of hydrogen, making it competitive with fossil fuels over time. They also attract government incentives and private investment, further reducing the financial burden on individual companies.

By prioritizing economics alongside sustainability, industries can position themselves as leaders in the clean energy revolution without breaking the bank.

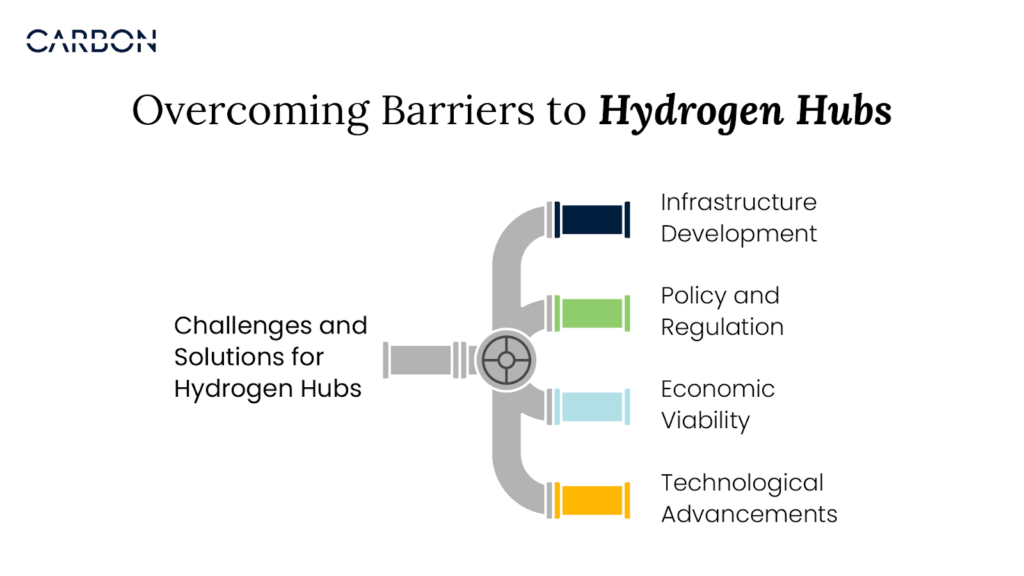

What’s Standing in the Way of Hydrogen Hubs—and How Do We Fix It?

The road to scaling hydrogen hubs isn’t without obstacles. But each of these challenges presents an opportunity for innovation and collaboration.

Technical Challenges

One of the biggest technical concerns is hydrogen embrittlement—the tendency of hydrogen to weaken metal pipelines over time. This makes adapting older infrastructure complex.

However, advances in material science are providing solutions, such as coatings and polymer liners that protect hydrogen pipelines while maintaining cost-effectiveness. Additionally, hydrogen-compatible pipeline designs are being developed for future-proofing new infrastructure.

Regulatory Hurdles

The lack of global standards for hydrogen infrastructure creates uncertainty for companies. Differing safety protocols, quality standards, and emissions targets can slow progress.

Governments and industries must work together to establish clear, unified regulations, as seen with Europe’s Hydrogen Strategy, which provides a roadmap for creating cross-border hydrogen corridors.

Market Readiness

Scaling hydrogen hubs requires a delicate balance of supply and demand. Without sufficient industrial or transportation customers, investments can stall.

Pilot projects, like those in Japan and South Korea, are bridging this gap by creating “hydrogen clusters” where localized production and consumption build momentum before scaling further.

The Path Forward

The challenges are significant, but they’re not insurmountable. Technical innovations, like advanced pipeline materials, are already closing the gap.

Collaborative policymaking is creating a foundation for consistent standards. And public-private partnerships are ensuring that hydrogen hubs can scale sustainably and efficiently.

Are Hydrogen Hubs the Key to a Cleaner Future?

We started with the question whether hydrogen hubs will drive the future of energy. Now, the question has changed — will industries seize this opportunity or risk being left behind?

Hydrogen hubs represent a broader opportunity: the chance to lead in building a sustainable energy future. Industries that act now will not only shape their own trajectories but also contribute to a cleaner, more resilient world.

FAQs

1. What is a hydrogen hub, and how does it support the clean energy transition?

A hydrogen hub is a centralized system that connects hydrogen production, storage, and distribution. By integrating renewable energy sources, industrial demand, and transportation networks, hydrogen hubs make it easier and more cost-effective to scale clean energy solutions. They act as key enablers in the global push toward decarbonization.

2. How can oil and gas infrastructure be repurposed for hydrogen production and distribution?

Existing oil and gas pipelines, storage tanks, and refineries can often be adapted for hydrogen with minimal upgrades. Pipelines designed for natural gas, for example, can carry hydrogen after undergoing material modifications to address technical challenges like hydrogen embrittlement. Storage facilities and refineries can also be re-engineered to handle hydrogen, saving time and costs compared to building new infrastructure.

3. What are the cost-saving benefits of converting existing pipelines and storage facilities for hydrogen?

Repurposing infrastructure can cost up to 80% less than building new systems, according to studies on hydrogen pipeline retrofits. It also accelerates deployment timelines, reducing capital expenditures and operational delays. Additionally, retrofitting minimizes environmental impacts by avoiding the need for new materials and construction.

4. What challenges exist in creating hydrogen hubs, and how can they be overcome?

Challenges include technical issues like hydrogen embrittlement, regulatory inconsistencies, and balancing supply with demand. These can be addressed through:

- Advances in materials and coatings for pipeline safety.

- Global collaboration to establish unified hydrogen standards.

- Pilot projects that create localized hydrogen clusters to build early demand.

5. Why are hydrogen hubs critical to scaling the hydrogen economy?

Hydrogen hubs centralize and streamline the production, storage, and distribution of hydrogen, making the clean energy transition faster, cheaper, and more efficient. By repurposing existing infrastructure, they also ensure scalability, turning hydrogen into a viable competitor to fossil fuels for industrial and transportation applications.